Swing-resistant electromagnetic hybrid active actuation mechanism

An electromagnetic hybrid and actuator technology, applied in the direction of electromagnets, electromagnets with armatures, mechanical equipment, etc., can solve problems such as less consideration of anti-sway performance, achieve simple and reliable installation methods, avoid stagnation, and increase magnetic field strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

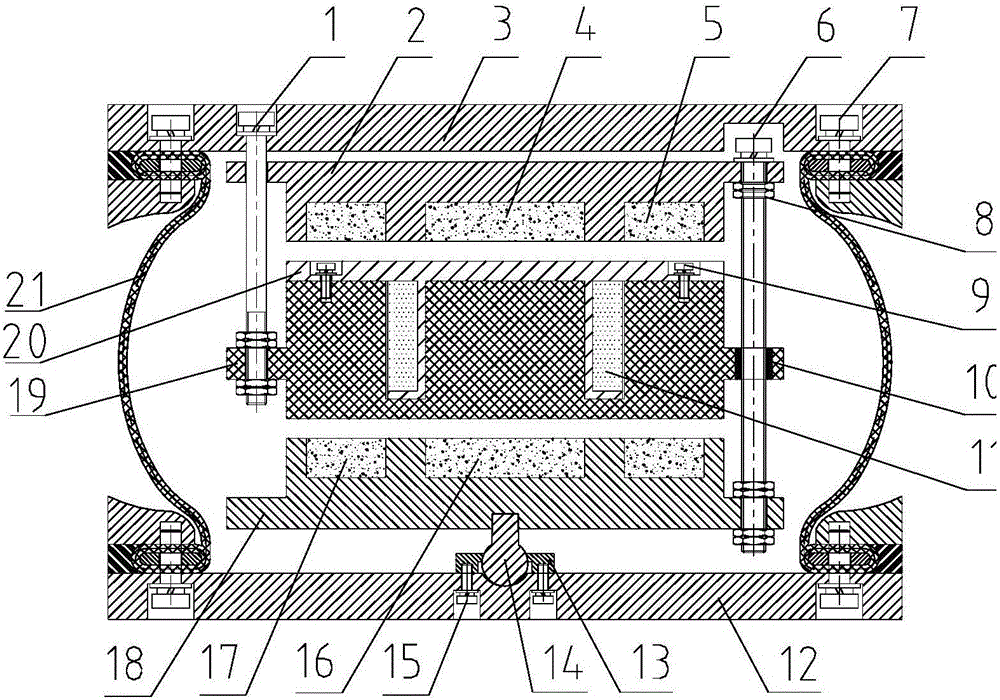

[0020] Refer to the attached drawings, an anti-sway electromagnetic hybrid actuator, which includes: middle screw 1, upper armature 2, upper cover plate 3, upper circular permanent magnet 4, upper annular permanent magnet 5, fixed screw 6, shell Locking bolt 7, locking nut 8, coil cage fixing bolt 9, linear bearing 10, coil winding 11, lower cover 12, ball head cover 13, ball head shaft 14, ball head shaft fixing bolt 15, lower circle Shaped permanent magnet 16, lower annular permanent magnet 17, lower armature 18, middle armature 19, coil holder 20 and airbag shock absorber body 21;

[0021] The overall structure from top to bottom is: upper cover 3, upper armature 2, coil holder 20, middle armature 19, lower armature 18 and lower cover 12;

[0022] The upper circular permanent magnet 4 and the upper annular permanent magnet 5 are respectively embedded in the central groove of the lower end surface of the upper armature 2 and the annular groove coaxial with the central groove;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com