Patents

Literature

116results about How to "Normal output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

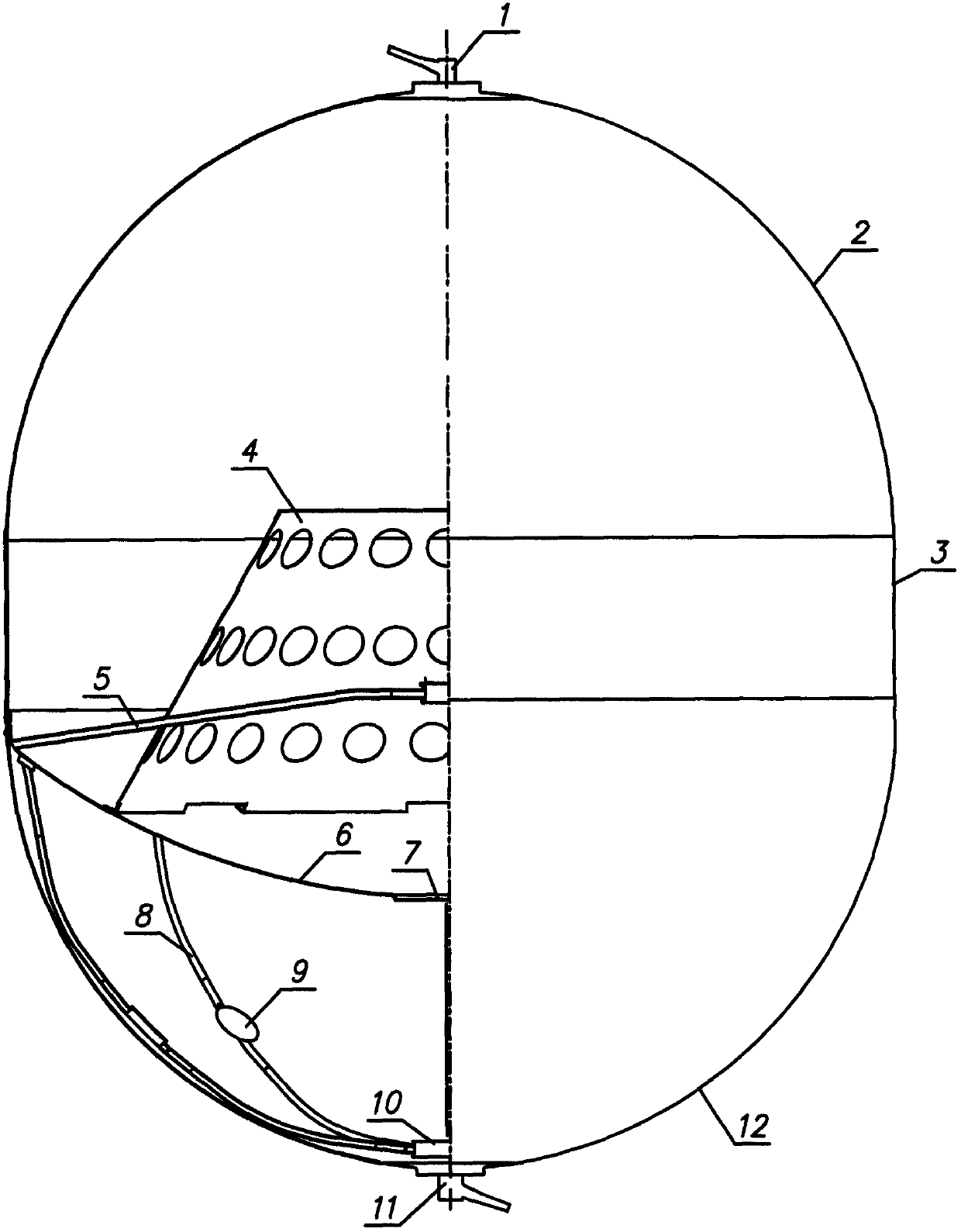

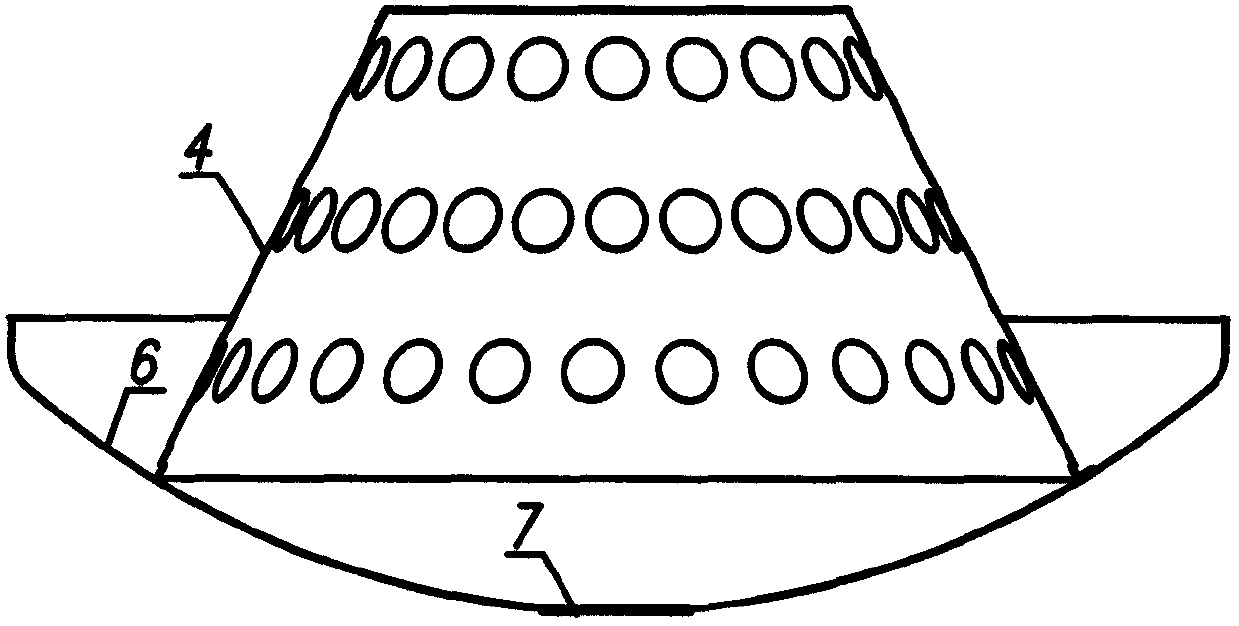

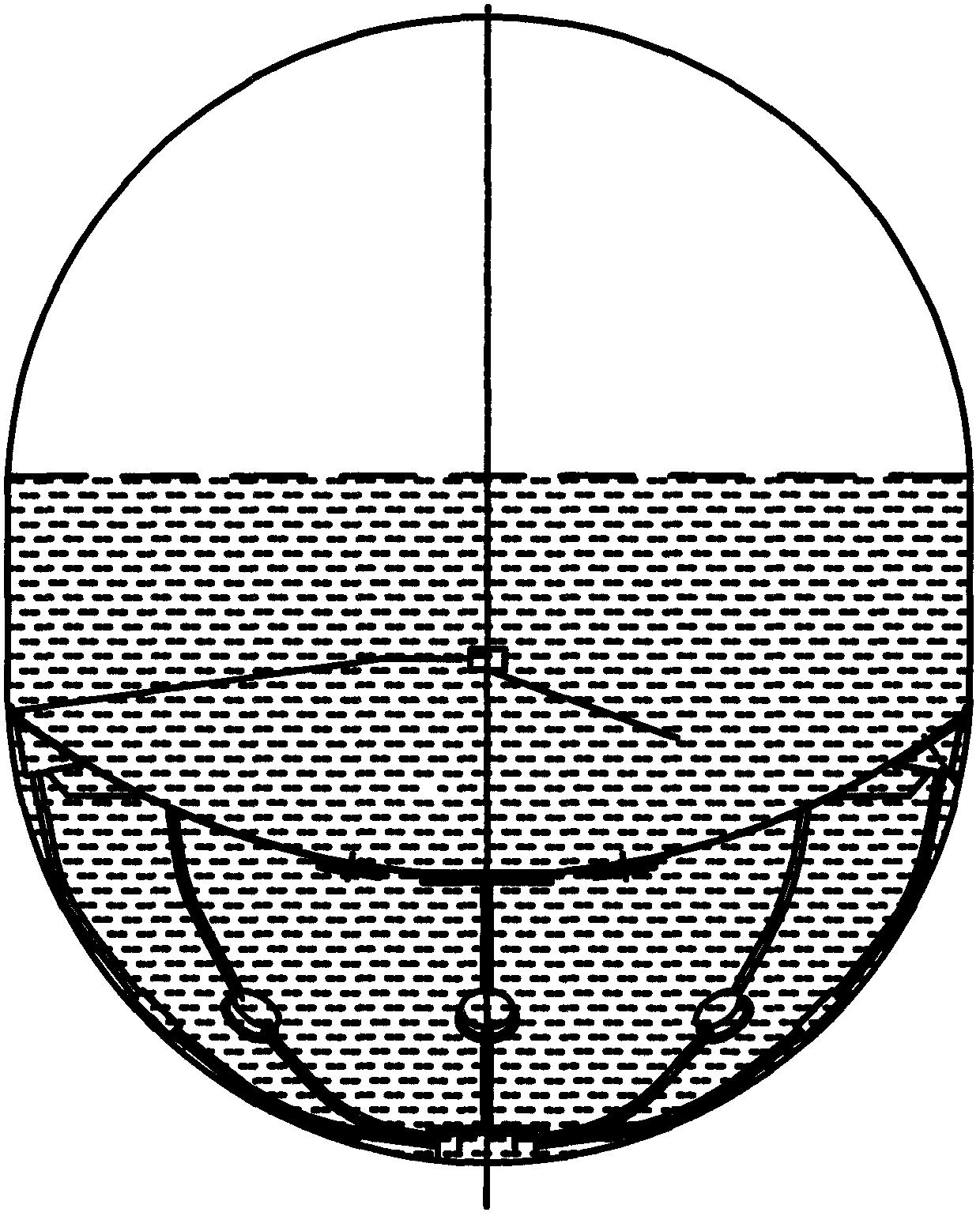

Light mesh-type surface tension storage tank

ActiveCN102991729AReduce intensityReduce weightCosmonautic propulsion system apparatusEngineeringSpherical form

The invention discloses a light mesh-type surface tension storage tank comprising a gas port, an upper half spherical head, a cylindrical section, an anti-sloshing cone, an exhaust cup, a middle bottom partition plate, a middle bottom collector, a collector connecting pipe, a middle connector, an air bubble trap, a liquid port and a lower half spherical head; the upper half spherical head is in argon arc welding with the cylindrical section, the gas port is in argon arc welding with the upper half spherical head, and the liquid port is in argon arc welding with the lower half spherical head; the middle bottom partition plate is welded together with the cylindrical section and the lower half spherical head and used for dividing the storage tank into an upper cabin and a lower cabin; the middle bottom collector is located on the middle bottom partition plate; the anti-sloshing cone and the middle bottom partition plate are welded and fixed together and located in the upper cabin of the storage tank; and the collector connecting pipe, the middle collector and the air bubble trap are connected to form a propellant management device and arranged in the lower cabin of the storage tank. The light mesh-type surface tension storage tank can be applied to various satellites and has the advantages of light weight, liquid sloshing inhibition, strong mechanical environment resistance capability and the like. After the height of the cylindrical section of the storage tank is modified, the volume of the storage tank can be expanded on the basis of not changing the installation way, so that serialization products can be formed.

Owner:BEIJING INST OF CONTROL ENG

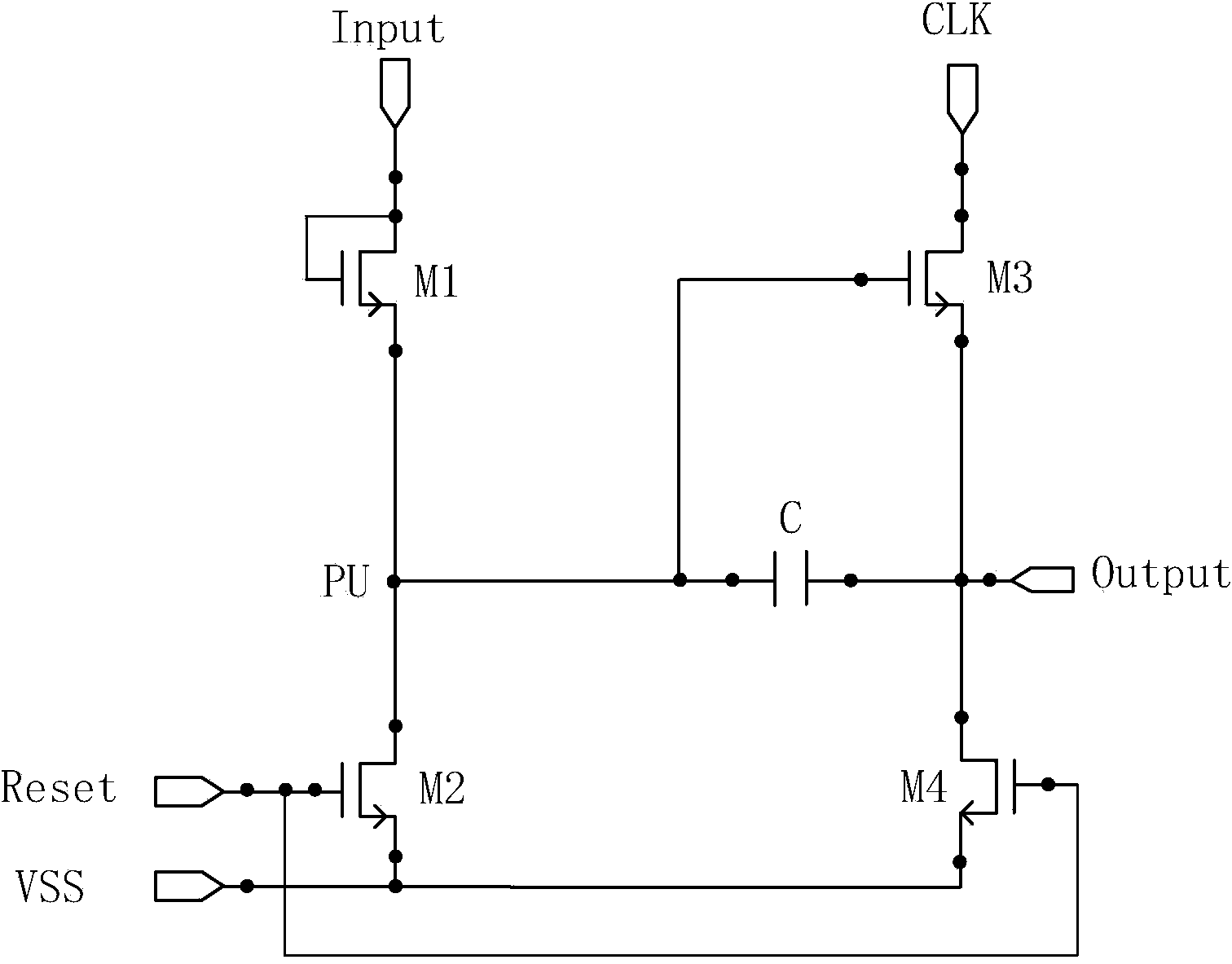

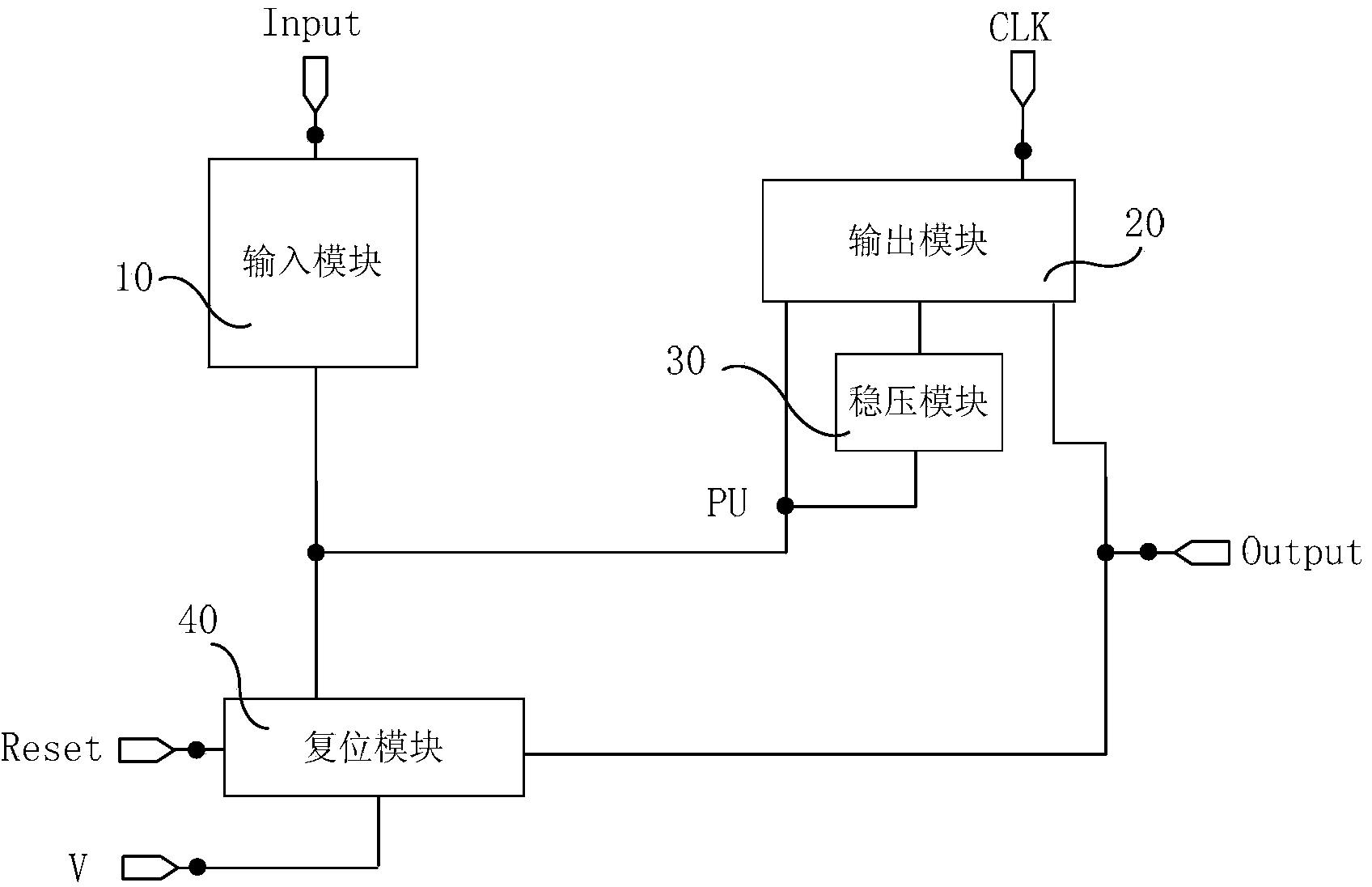

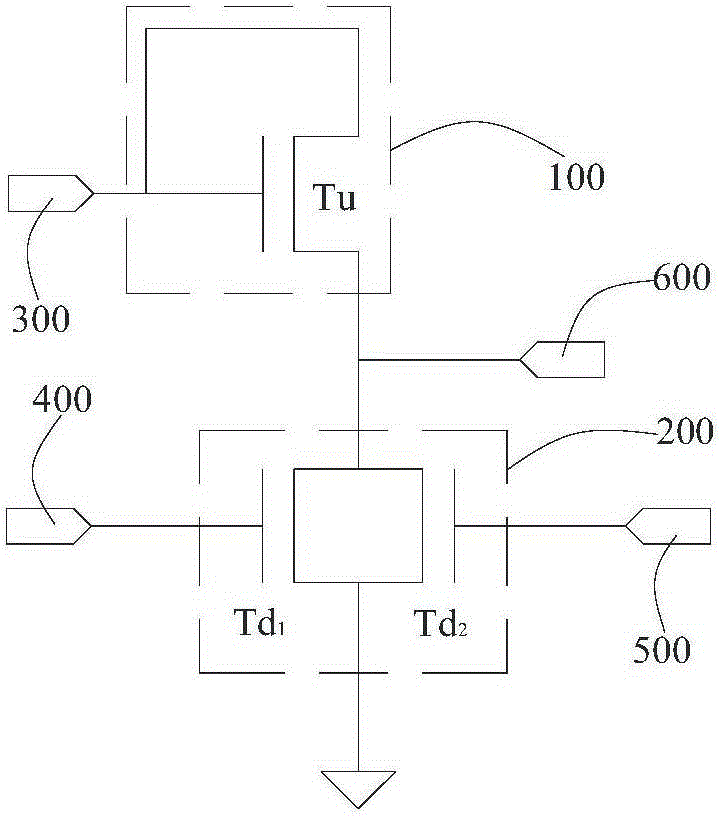

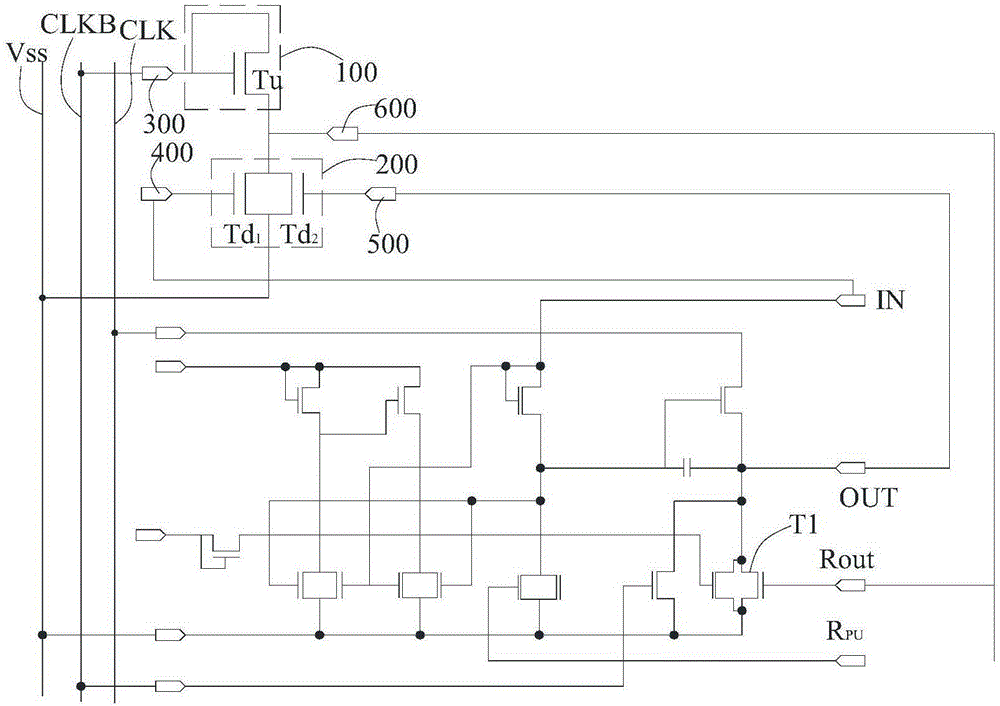

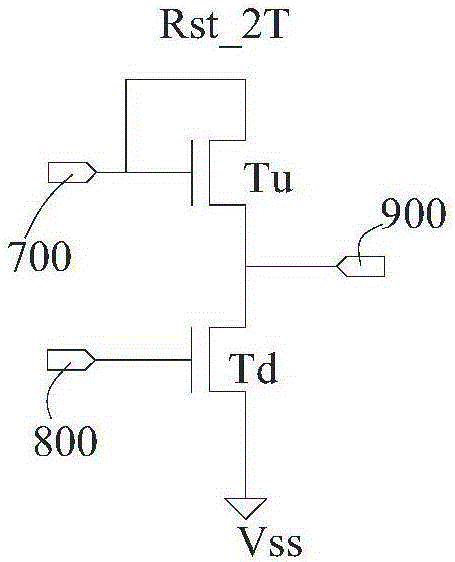

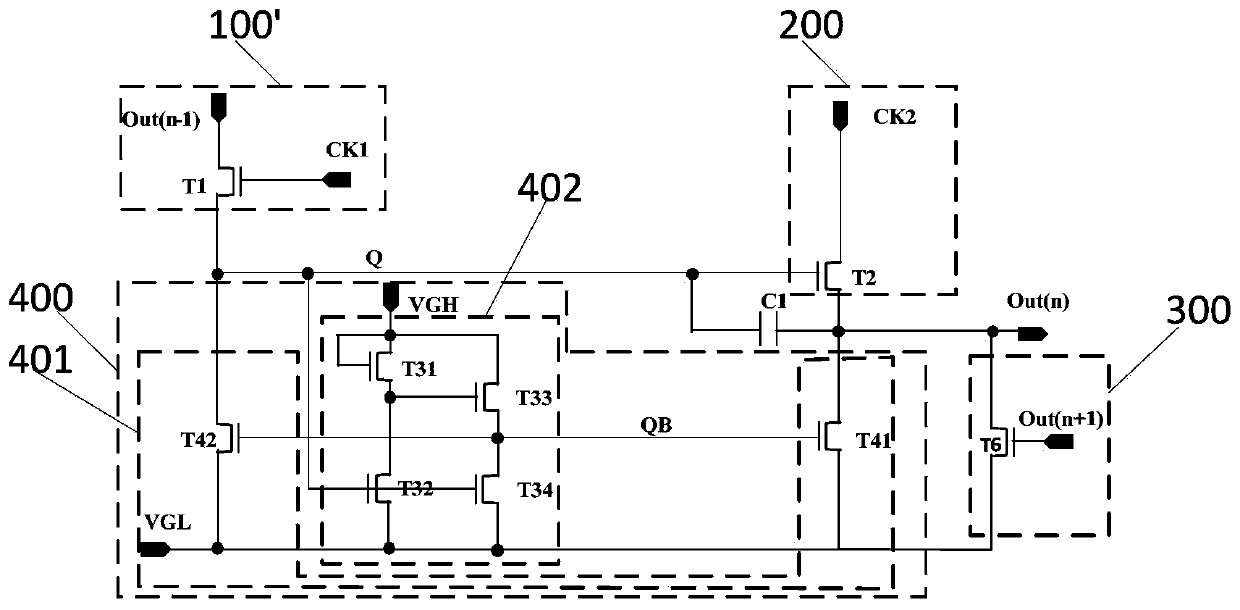

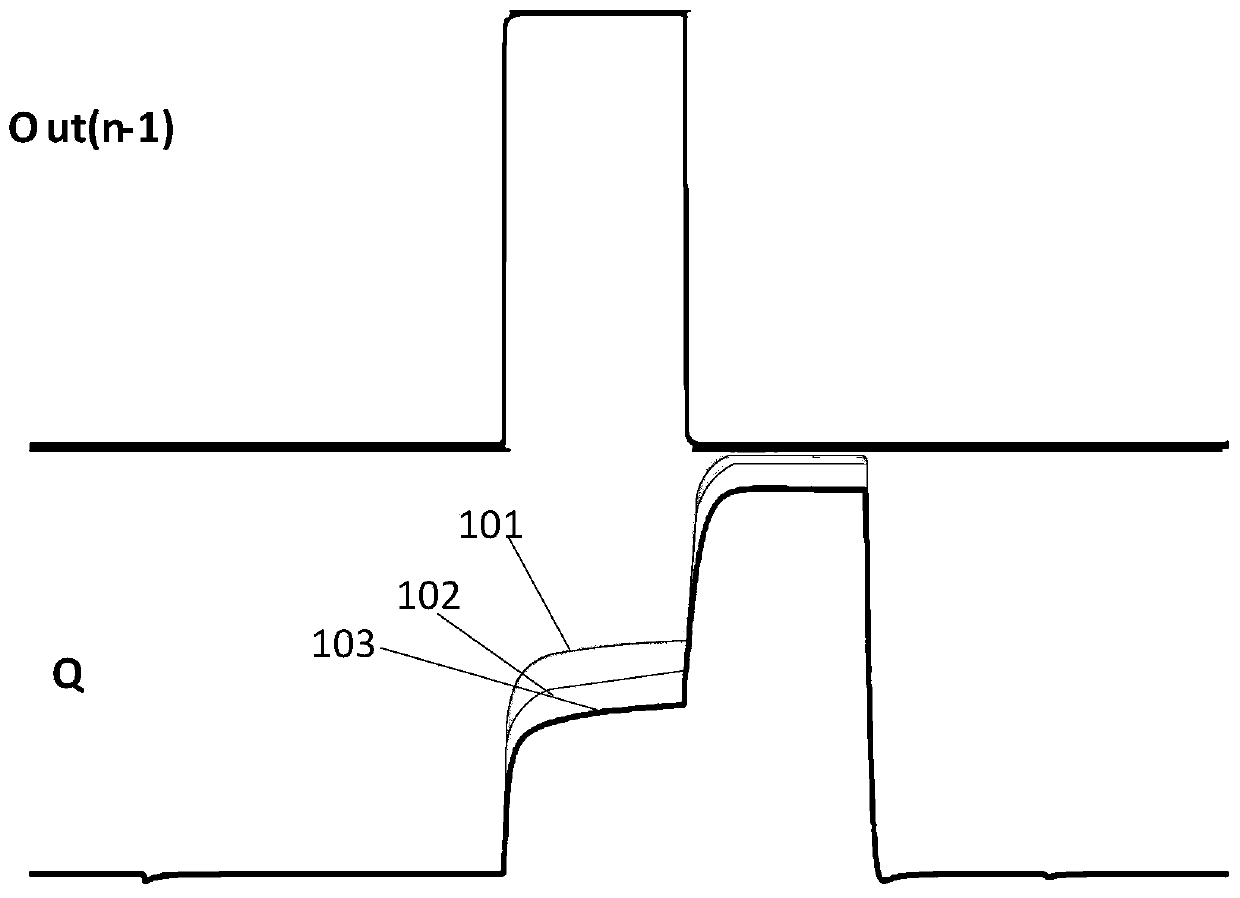

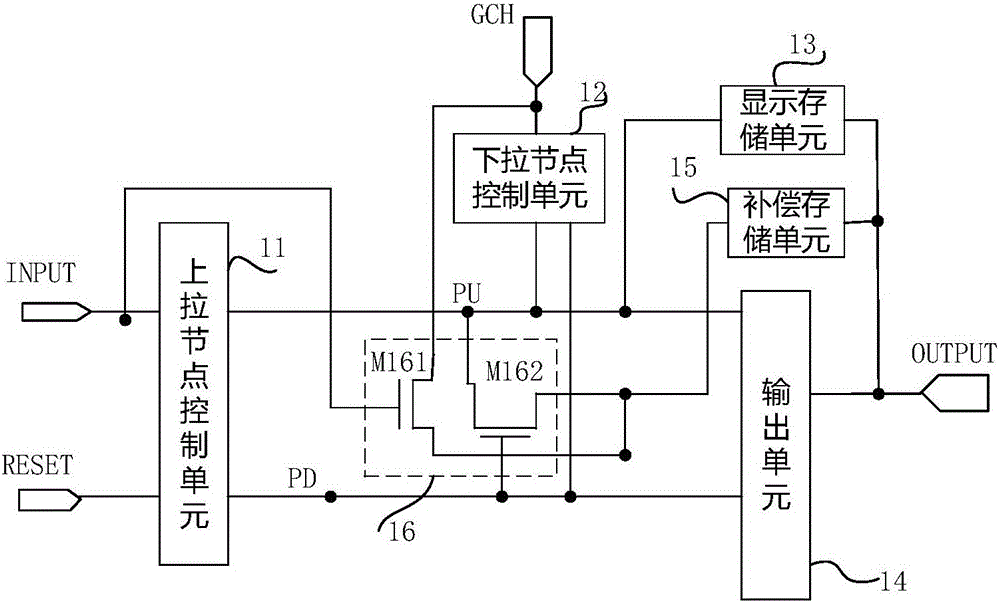

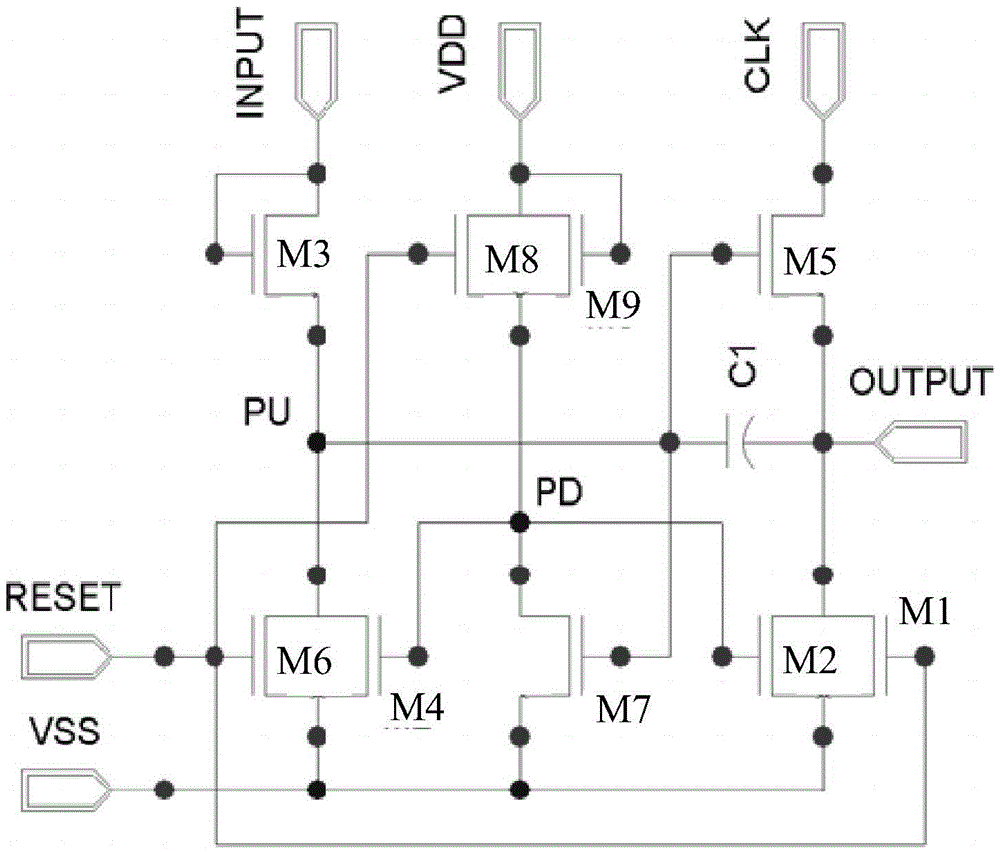

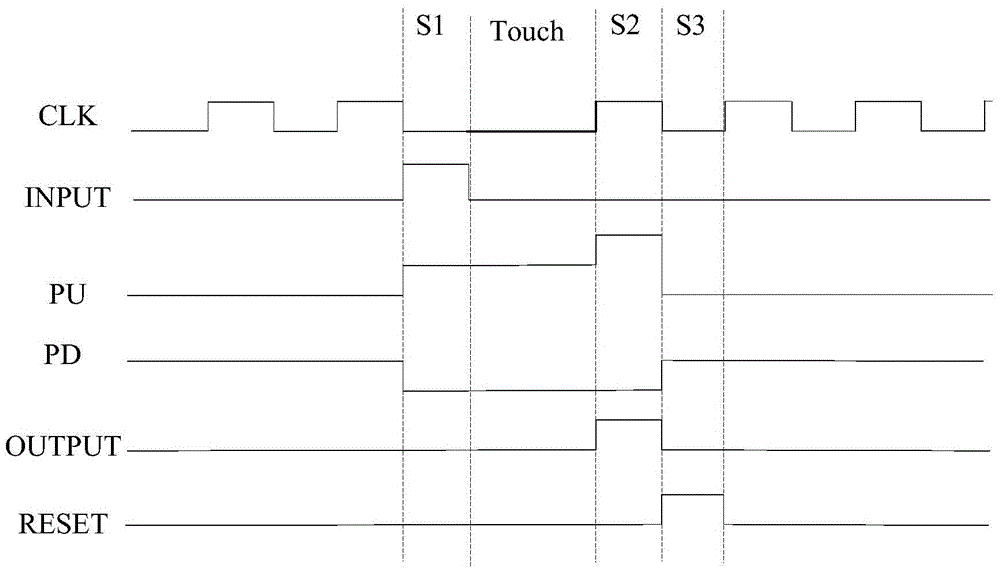

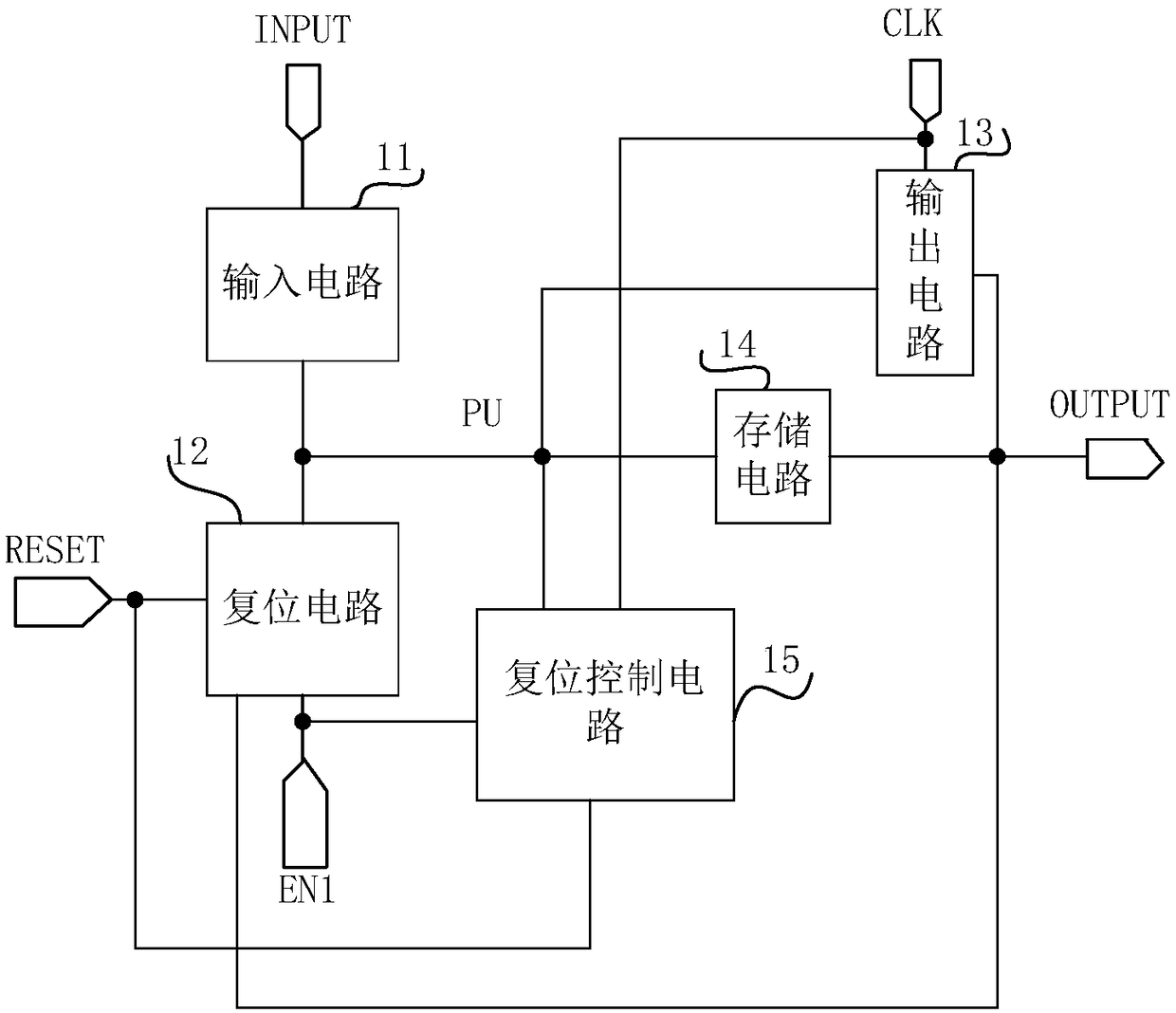

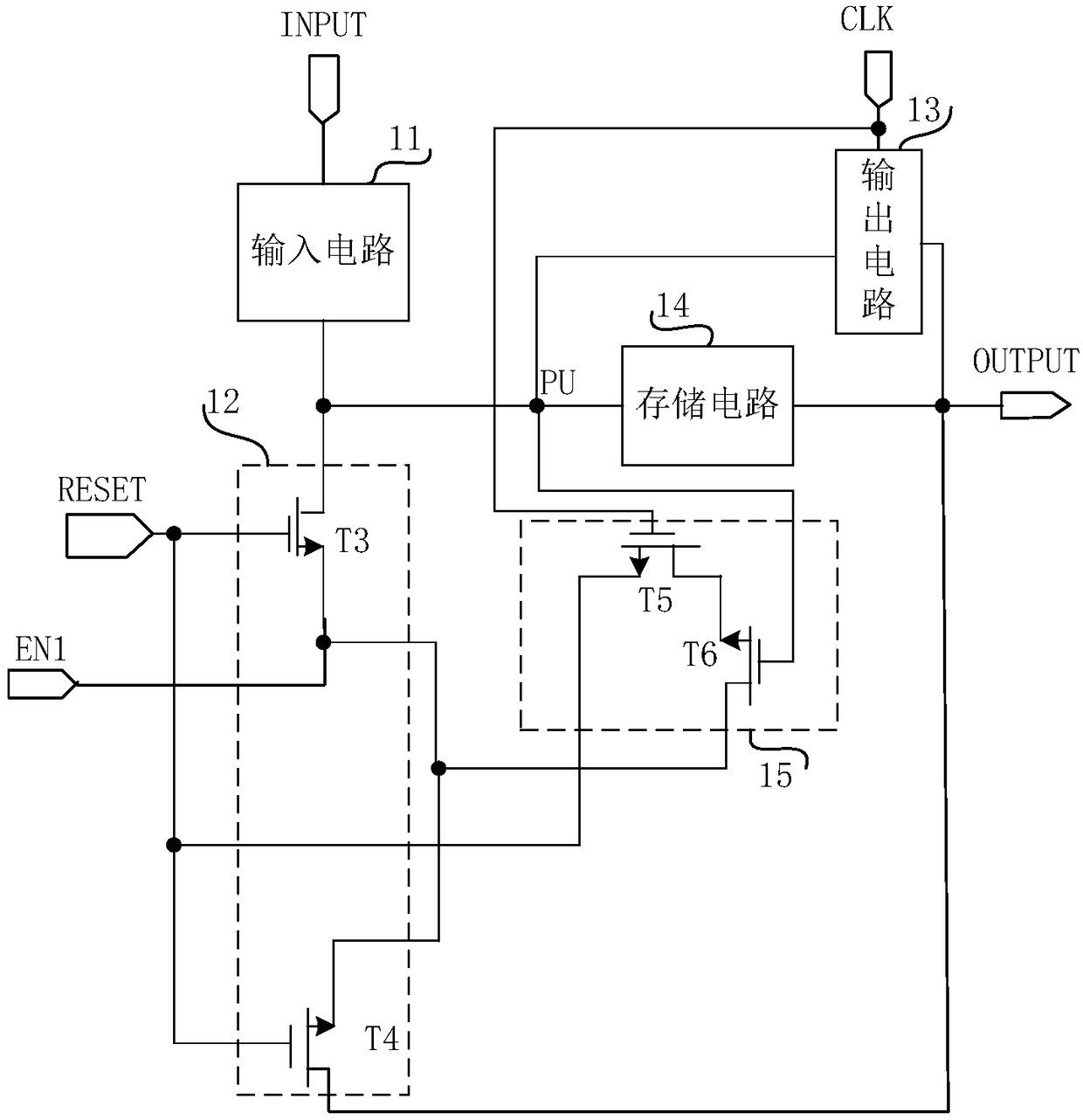

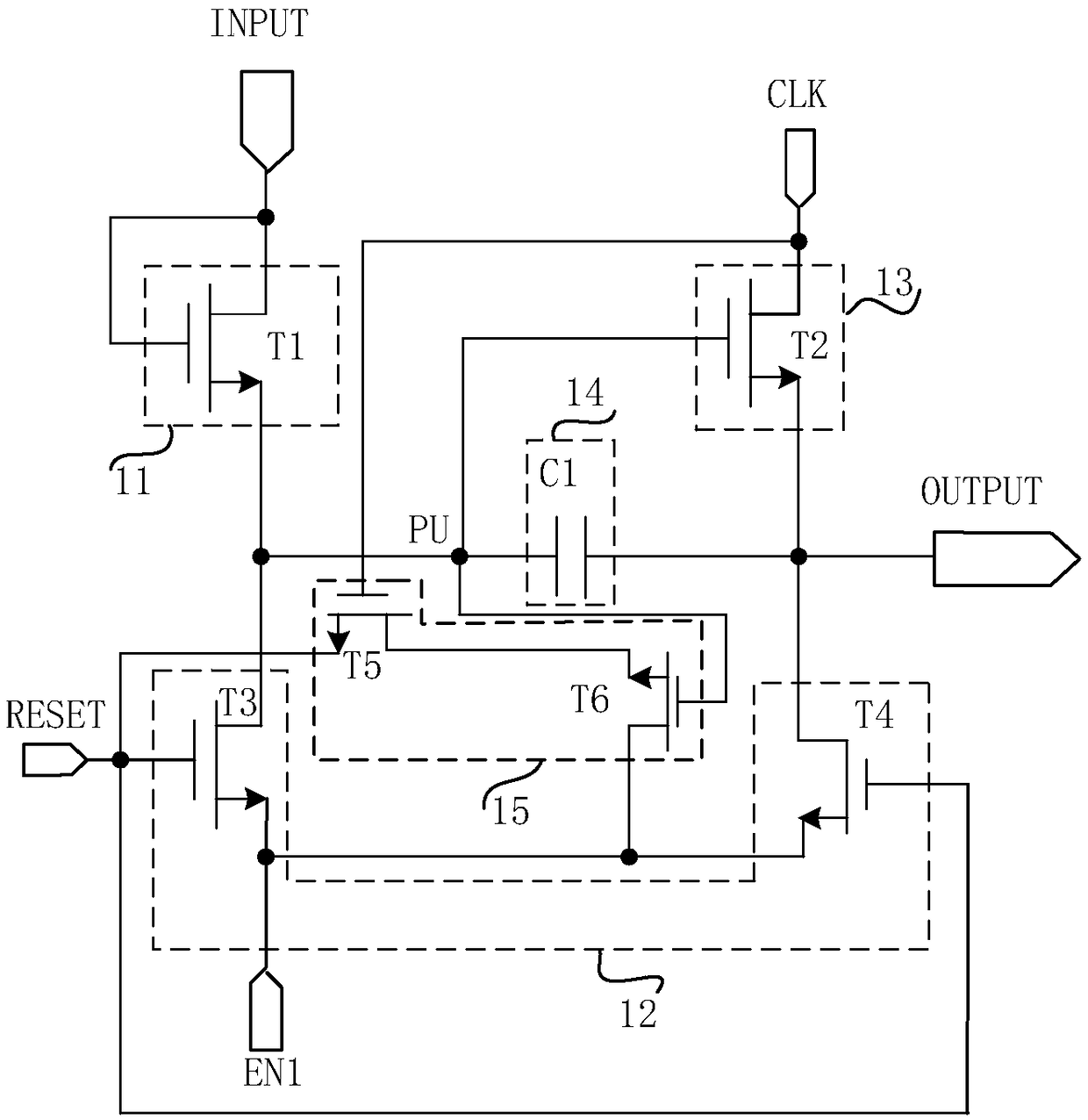

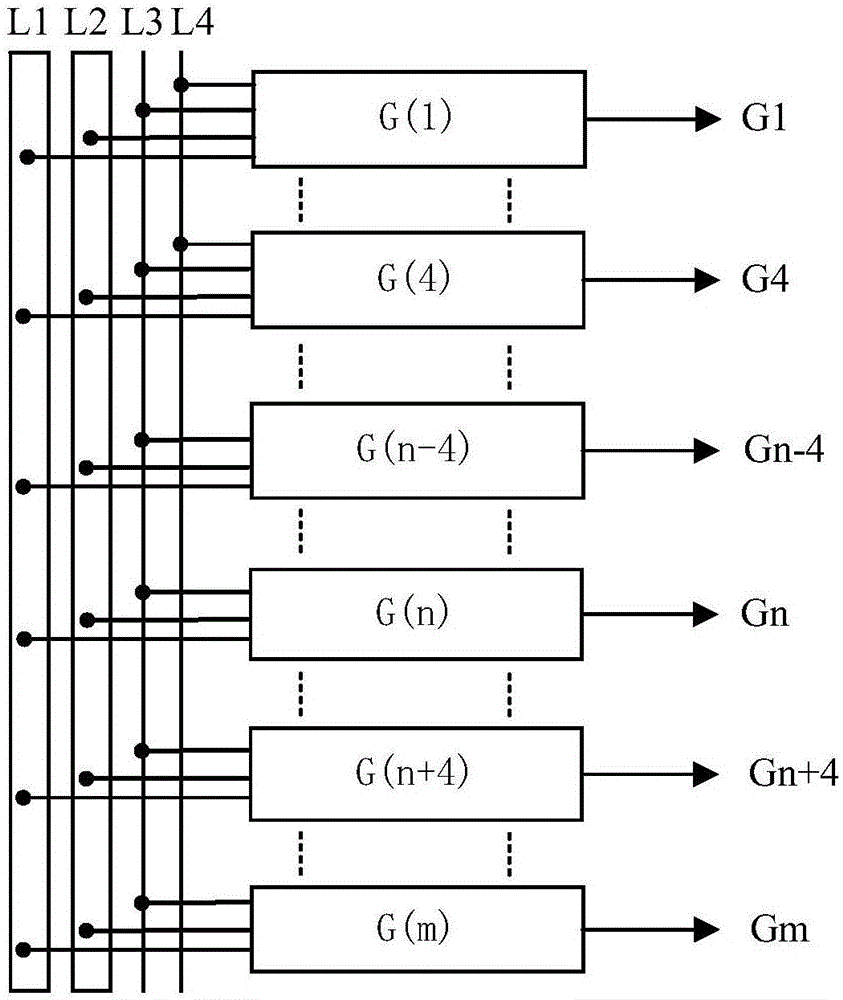

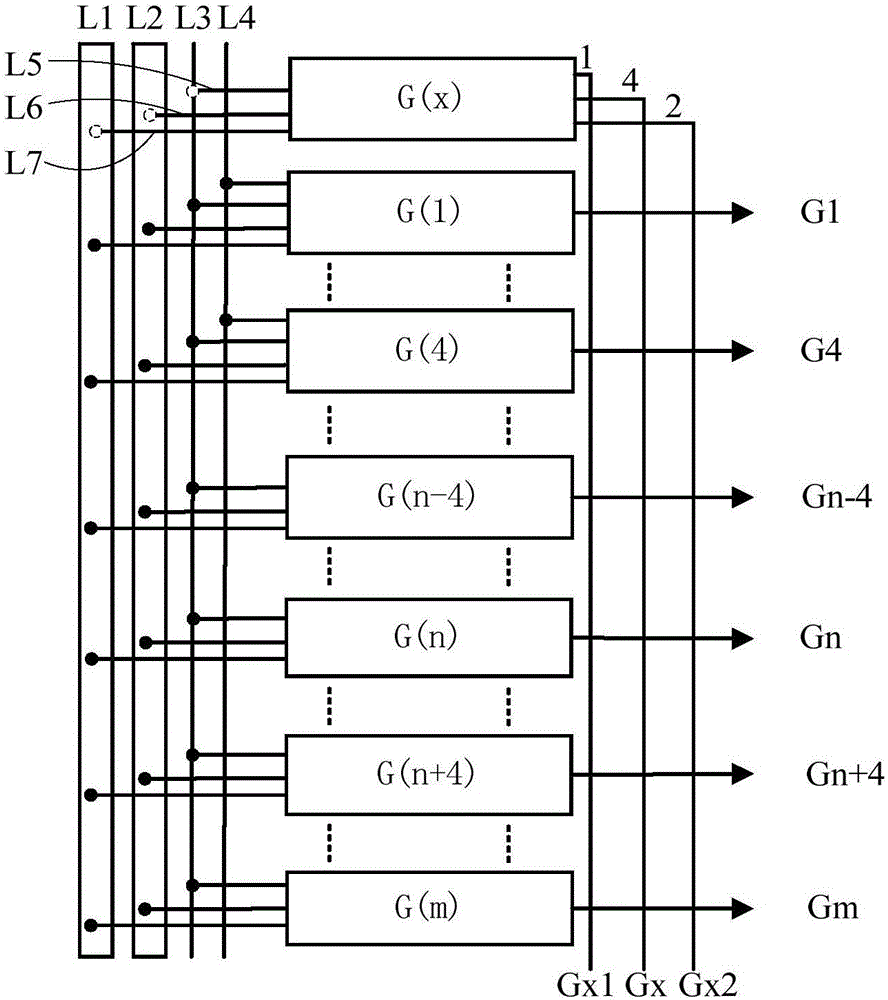

Shift register unit, gate drive circuit and display device

ActiveCN104167192ANormal outputImprove stabilityStatic indicating devicesDigital storageShift registerDisplay device

The embodiment of the invention provides a shift register unit, a gate drive unit and a display device and relates to the technical field of display so as to prevent that a level of a pull-up control node which should be at a high-level state is mistakenly driven down. The shift register unit includes an input module, an output module, a voltage stabilizing module and a resetting module.

Owner:BOE TECH GRP CO LTD +1

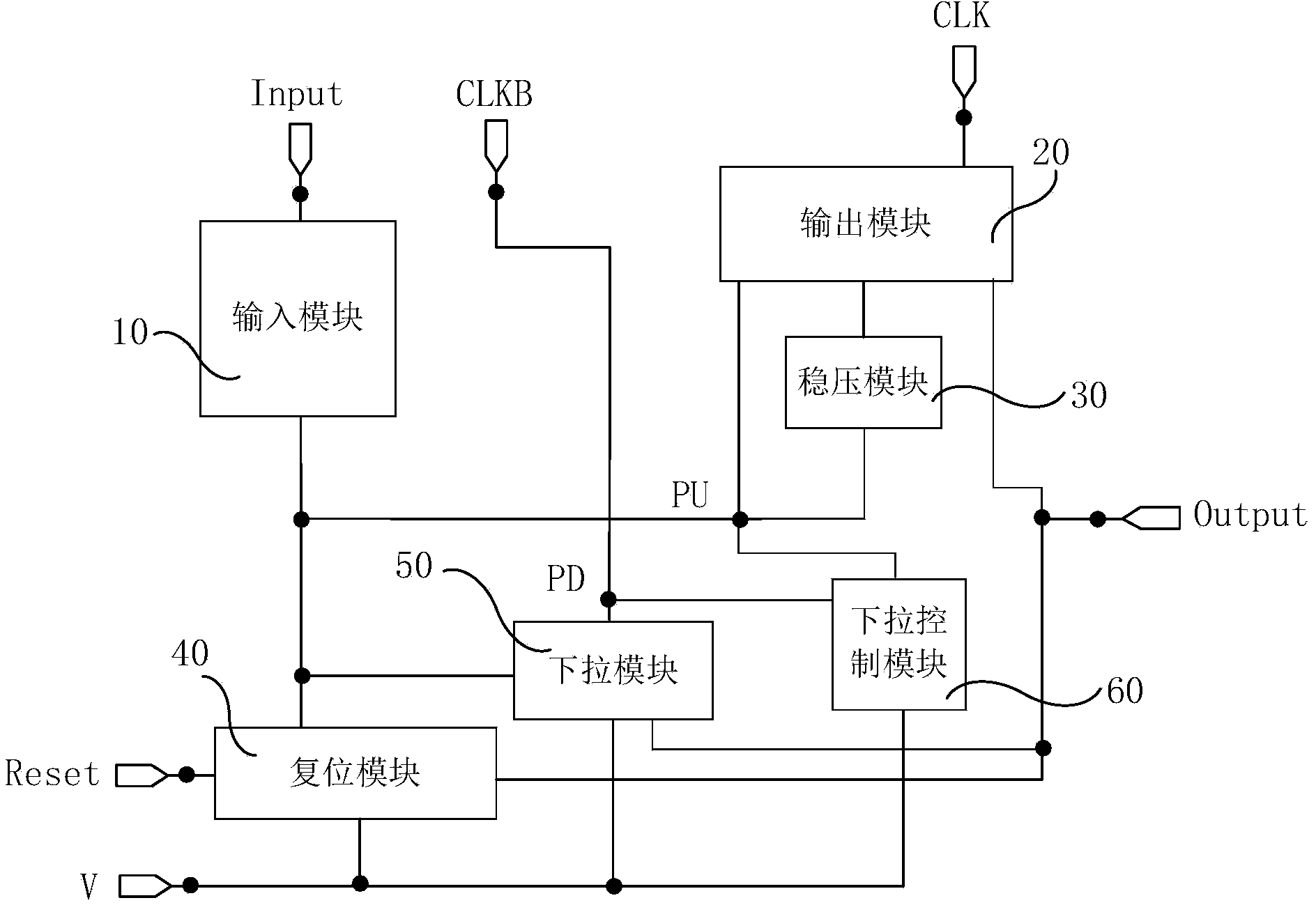

GOA drive circuit

ActiveCN105513550AEliminate the risk of failureImprove stabilityStatic indicating devicesDigital storageControl signalGate driver

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

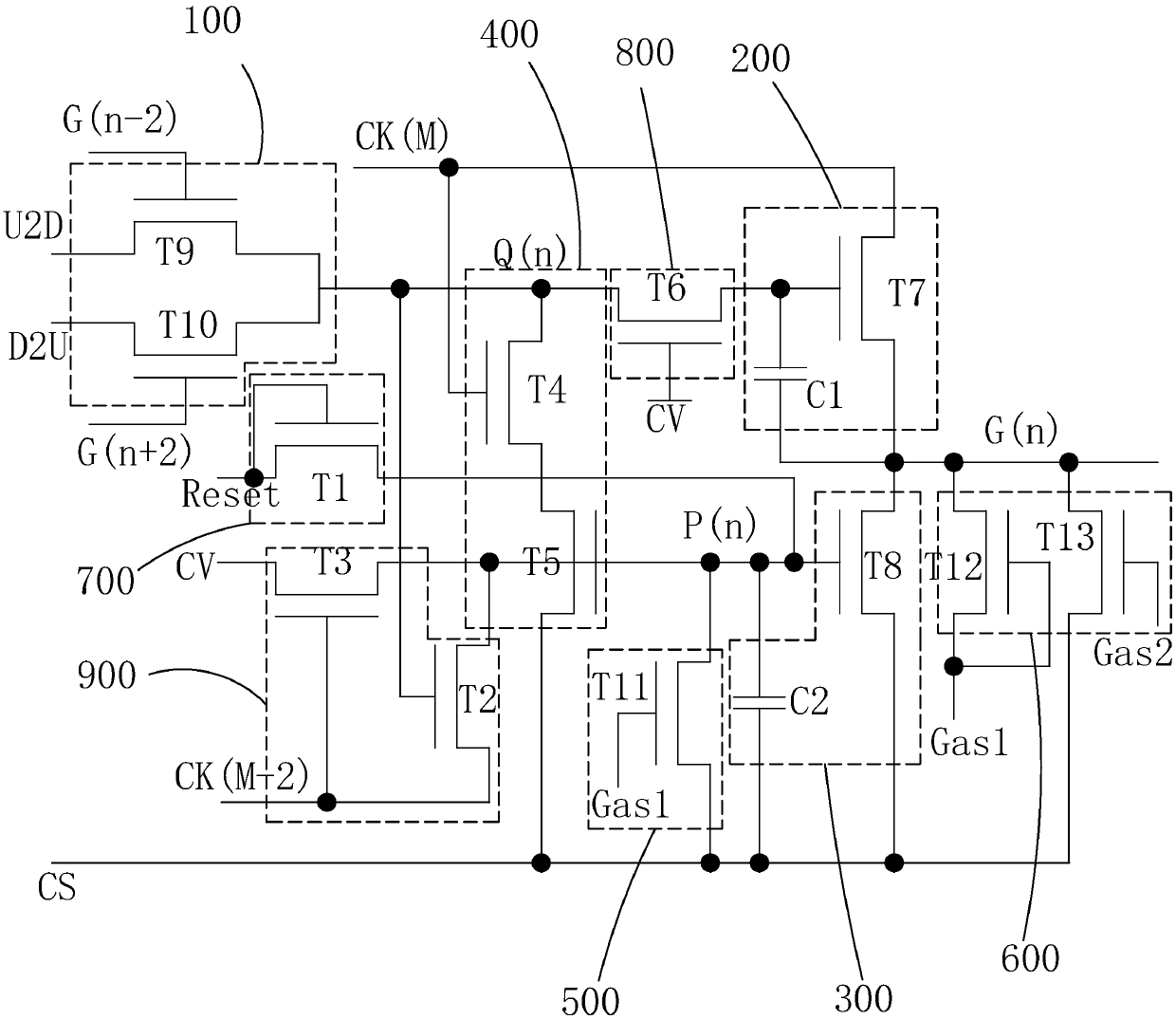

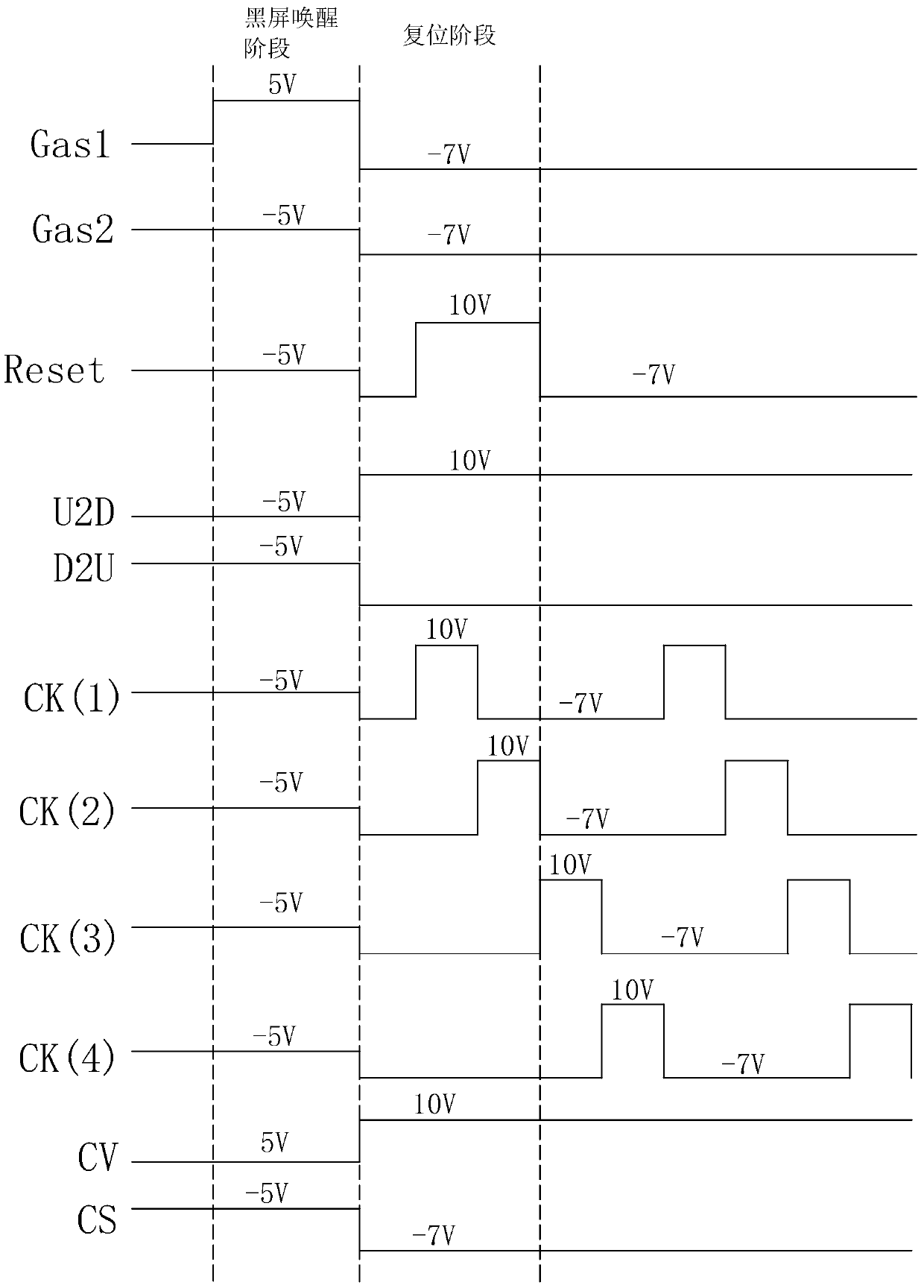

GOA circuit

ActiveCN108766380AIncrease the resistance valueNormal outputStatic indicating devicesDigital storageHemt circuitsEngineering

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

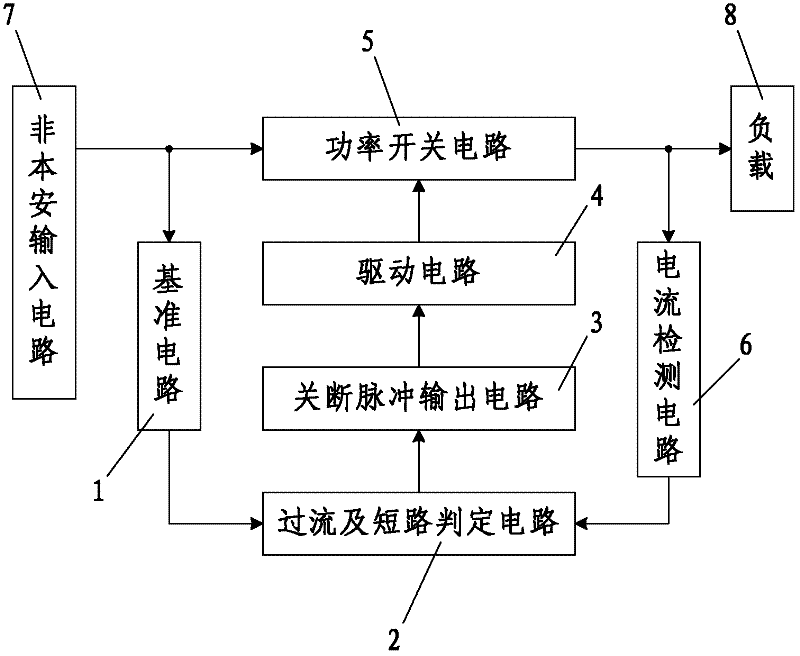

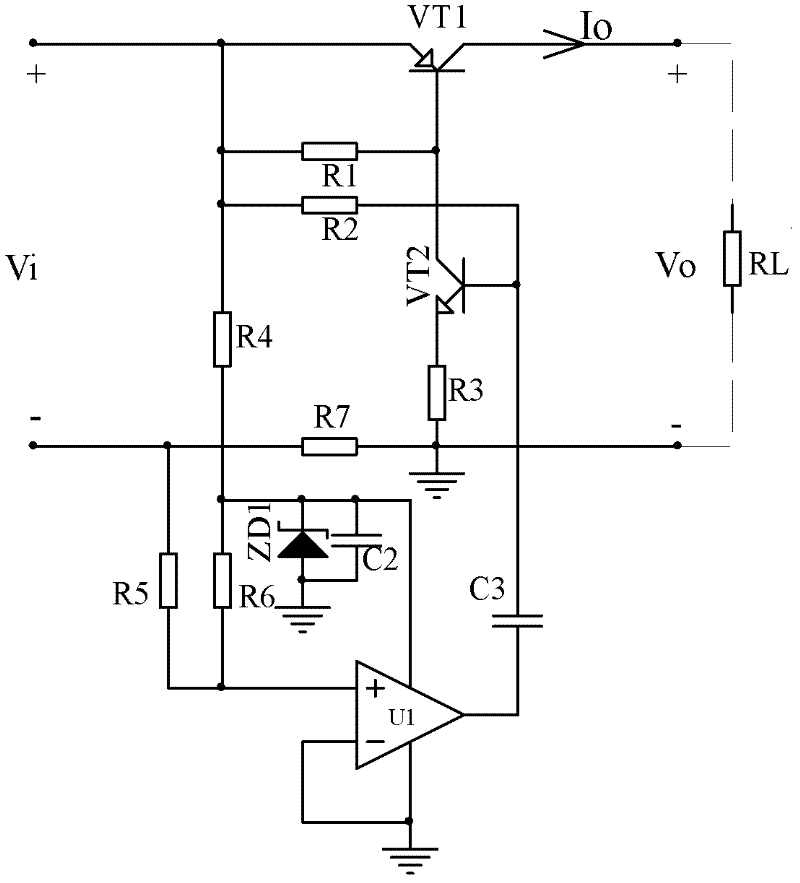

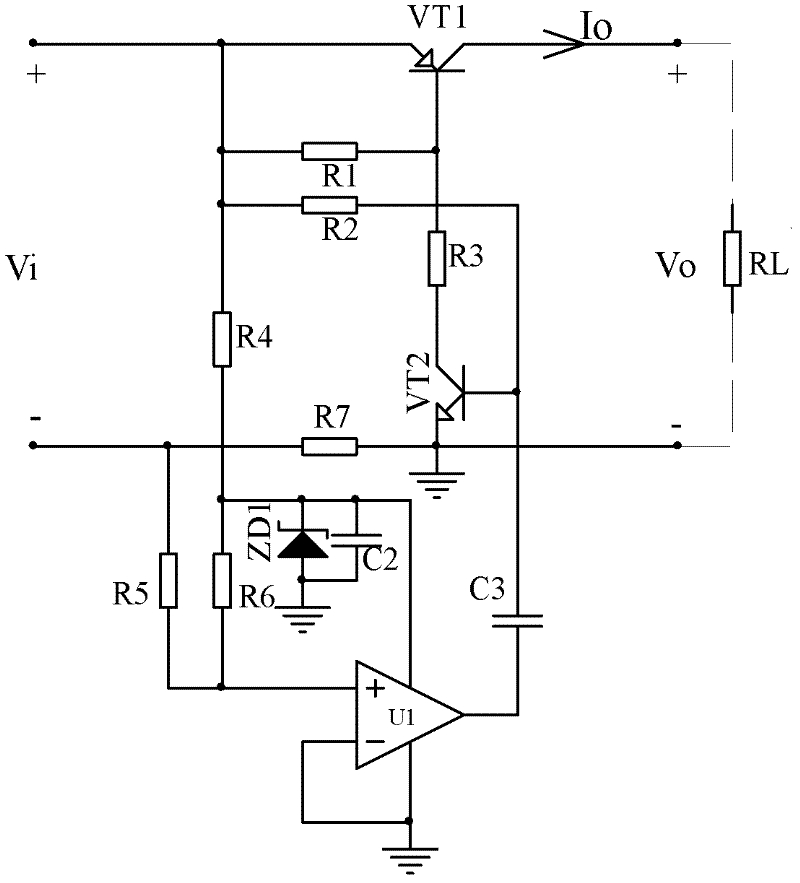

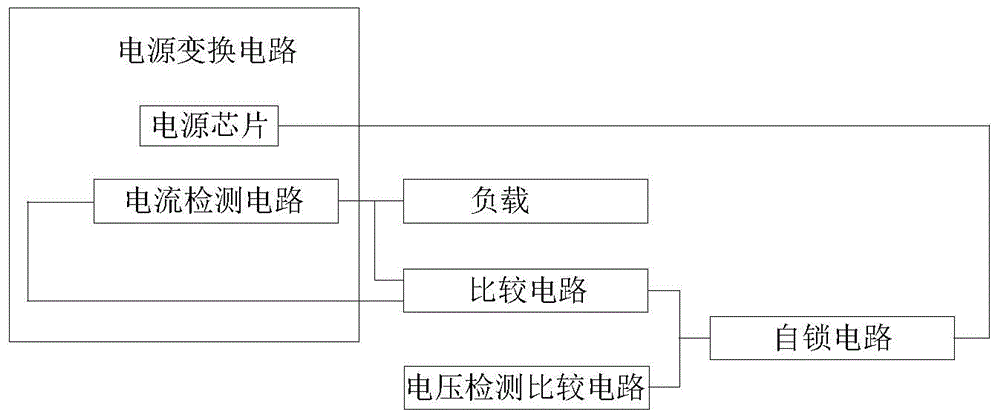

Self-recovery stop type protection circuit for low-voltage and high-power safety barrier

ActiveCN102420413ASimple circuit structureNovel and reasonable designArrangements responsive to excess currentControl switchSelf recovery

The invention discloses a self-recovery stop type protection circuit for a low-voltage and high-power safety barrier. The self-recovery stop type protection circuit comprises a power switching circuit which is connected between a non intrinsic safety input circuit and a load and used for controlling switch-on and switch-off of a circuit, a current detection circuit which is connected with the power switching circuit and used for detecting current in the circuit in real time, an overcurent and shortcircuit judgment circuit which is connected with the current detection circuit, a switch-off pulse output circuit which is connected with the overcurent and shortcircuit judgment circuit, and a driving circuit which is connected with the switch-off pulse output circuit, wherein the input end of the overcurent and shortcircuit judgment circuit is connected with a reference circuit; the reference circuit is connected with the non intrinsic safety input circuit; and the driving circuit comprises an oscillation circuit for making the power switching circuit automatically re-switch on after the power switching circuit is switched off. The self-recovery stop type protection circuit has a simple structure, low power loss, high output power, a wide application range and high popularization and application value; the normal transmission of high-power electric energy is not influenced; and a requirement for intrinsic safety output is met.

Owner:XIAN UNIV OF SCI & TECH

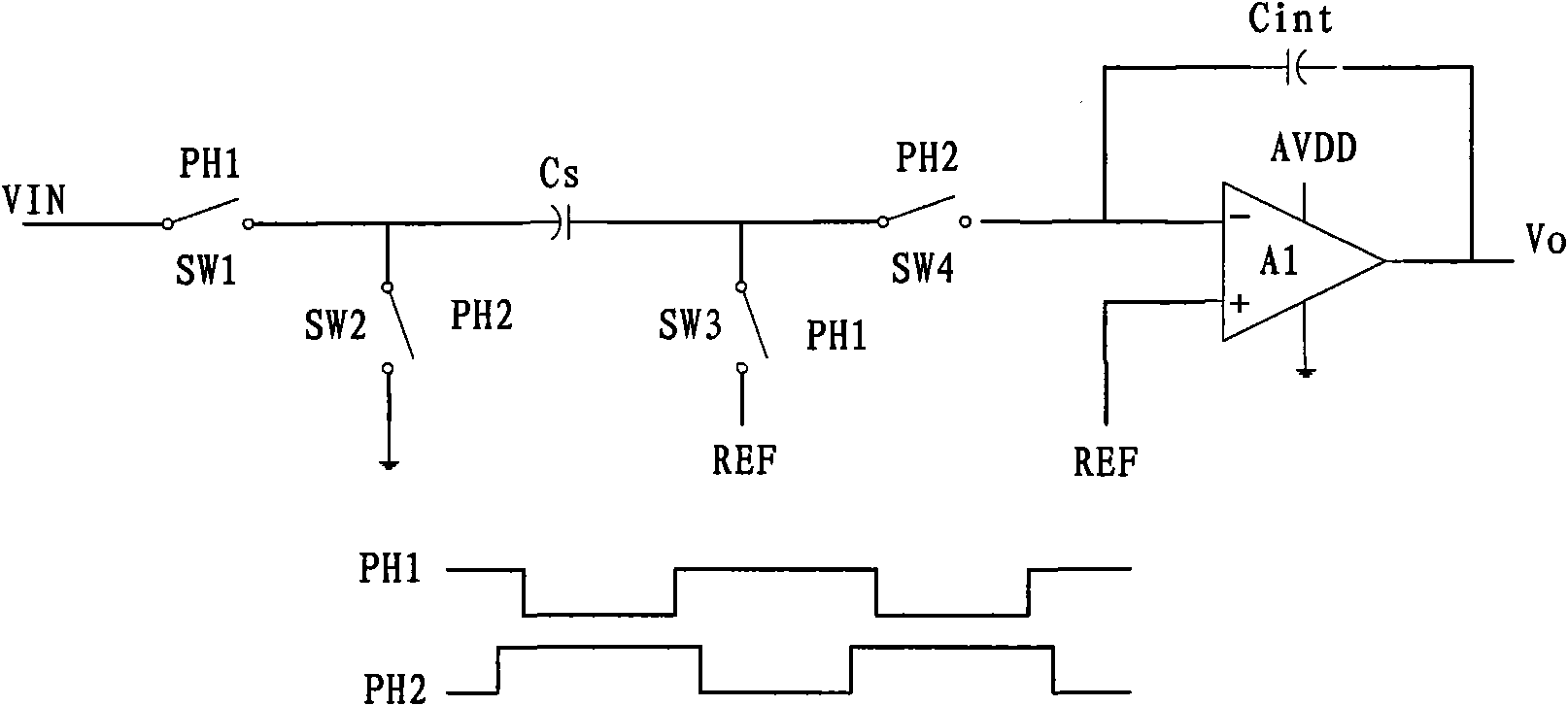

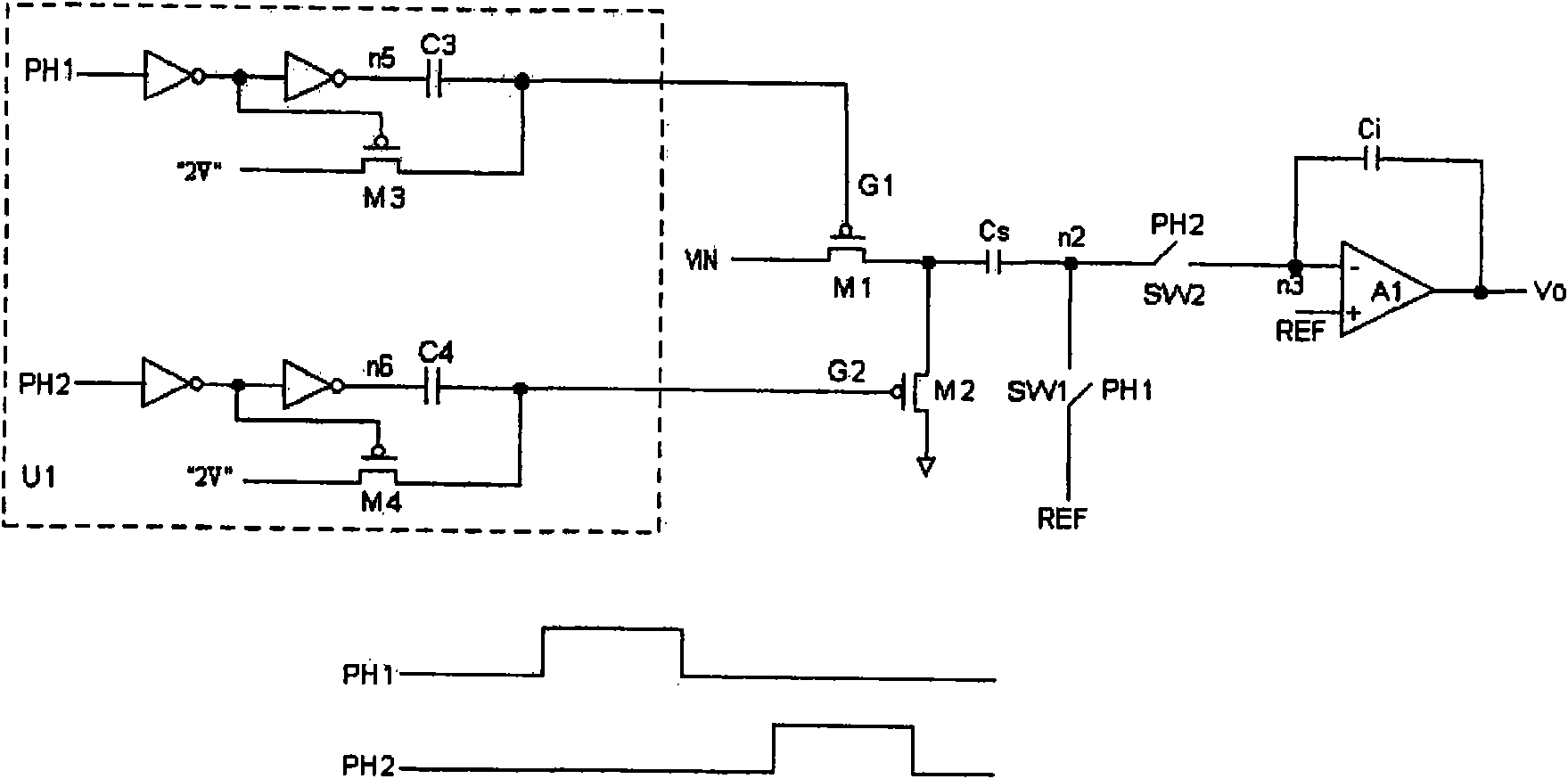

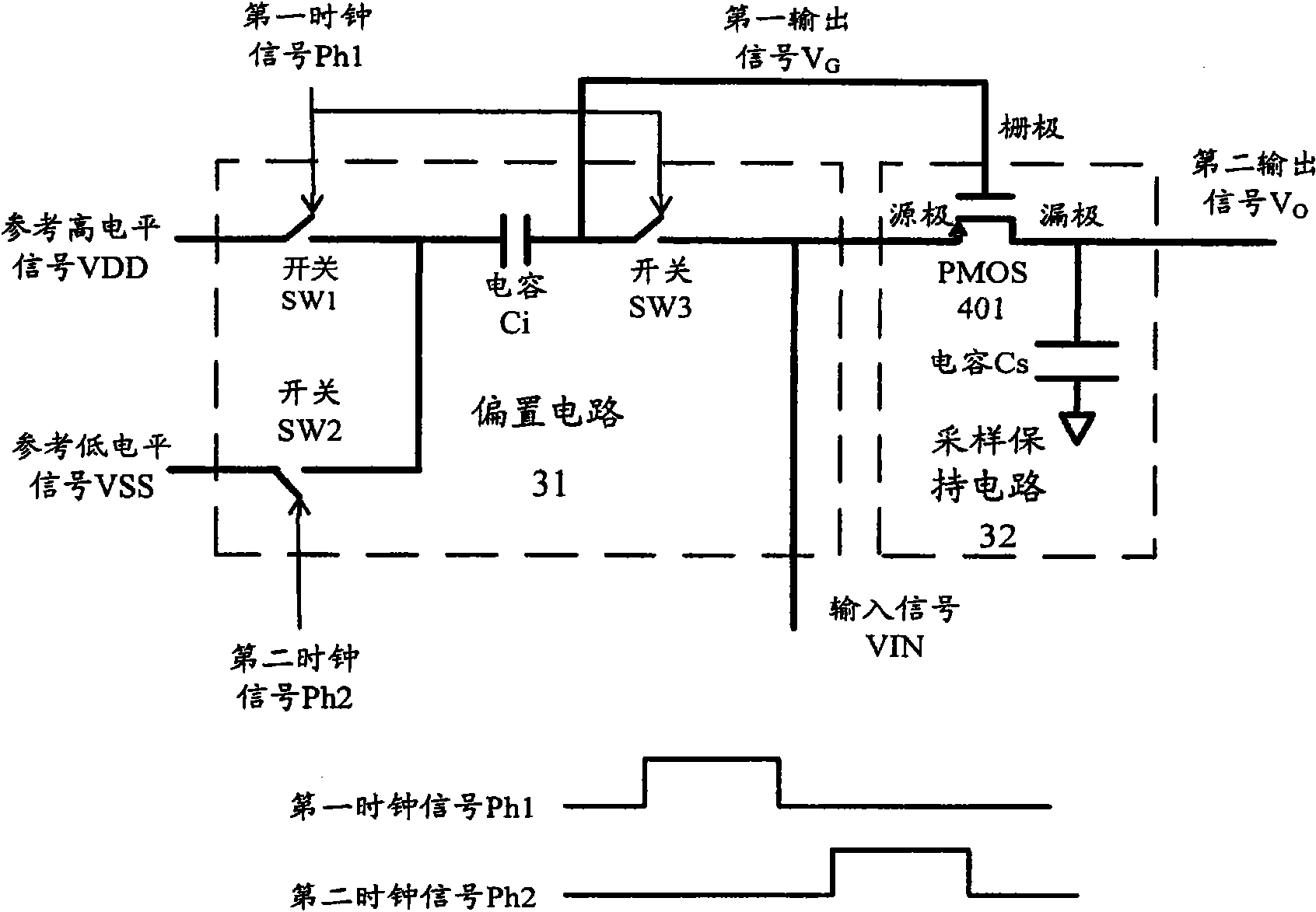

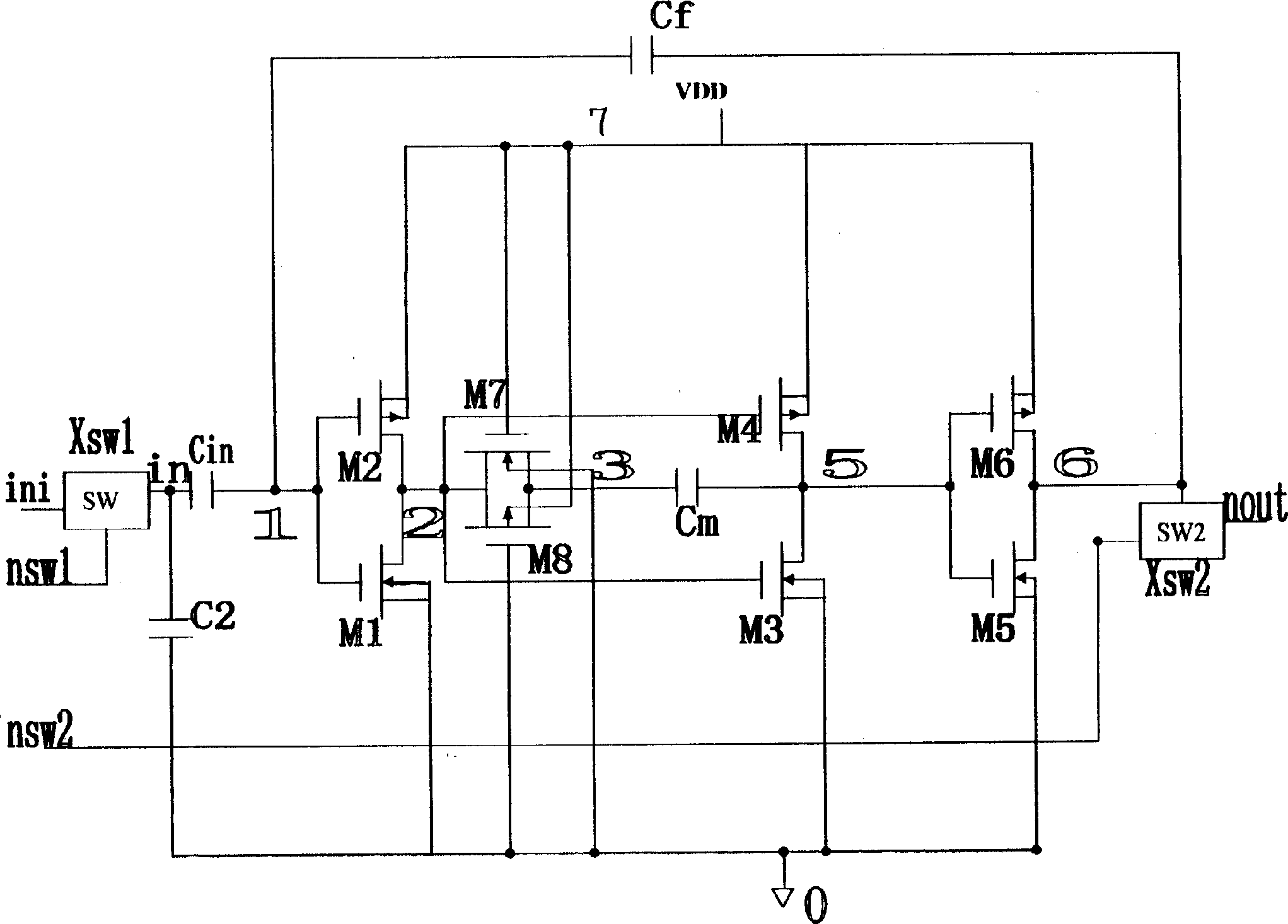

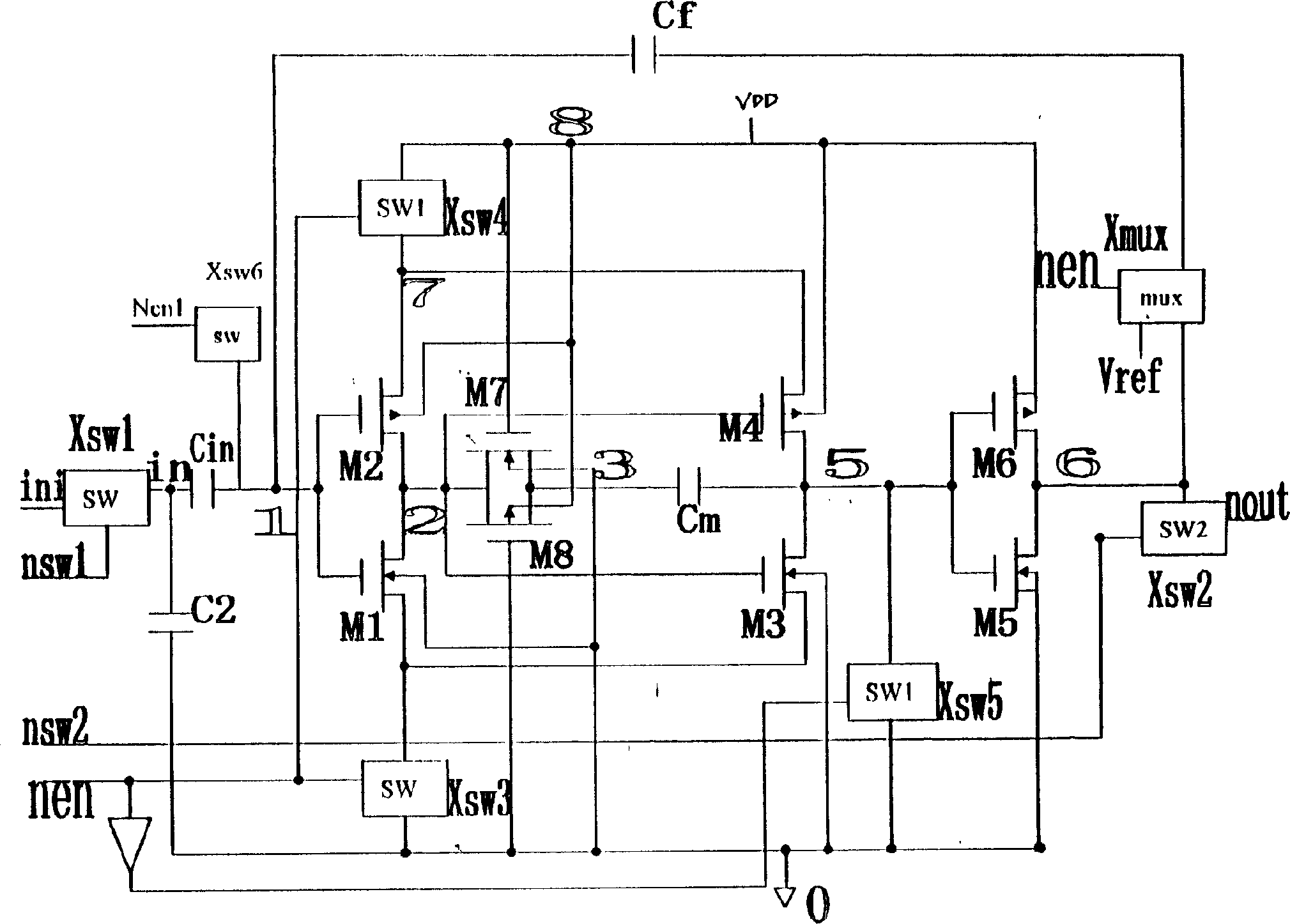

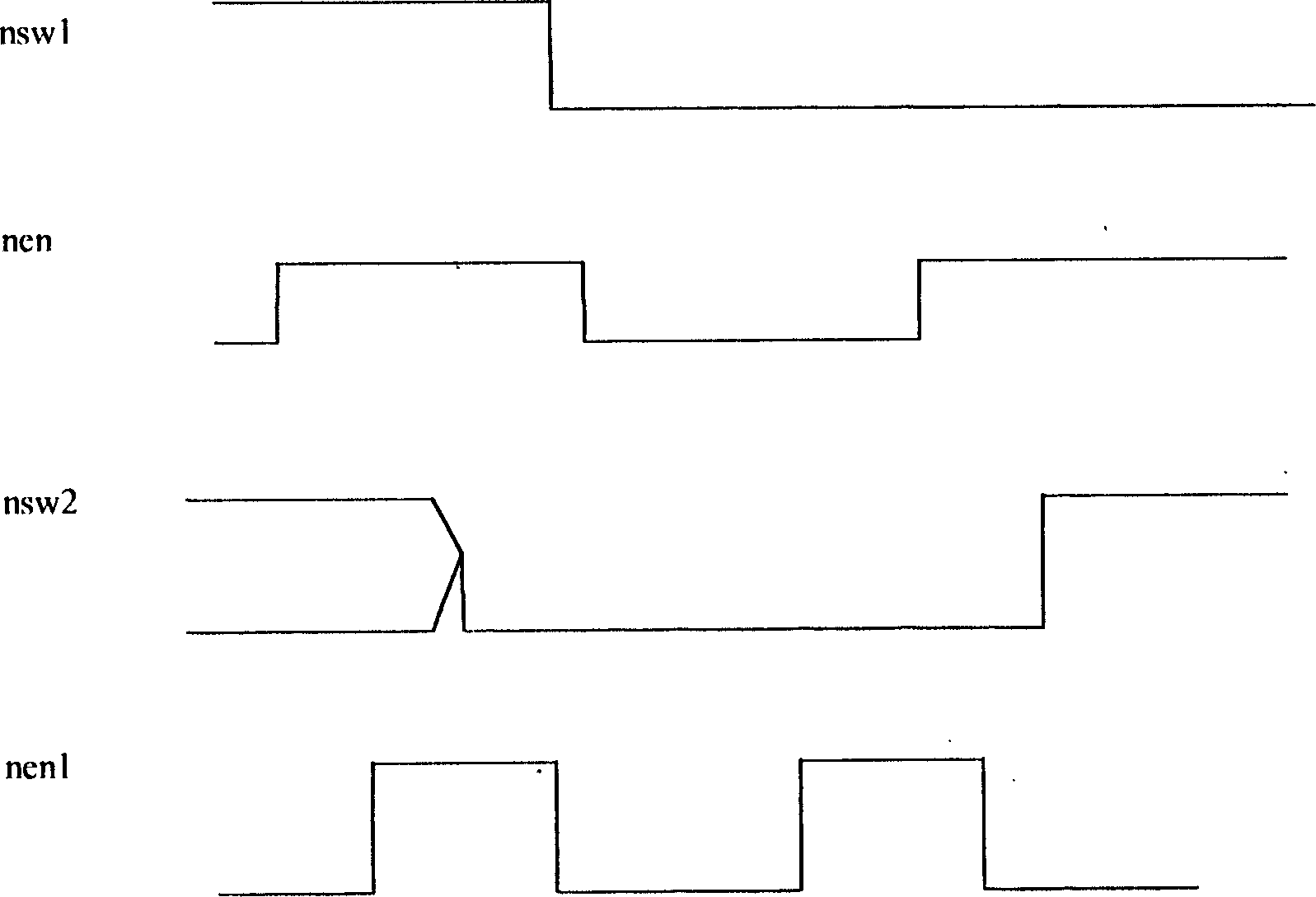

Analog signal sampling circuit and switch capacitance circuit

ActiveCN101587753ASignal distortion is smallAchieving High Linearity SamplingAnalogue/digital conversionElectric analogue storesElectrical resistance and conductanceCapacitance

The present invention provides an analog signal sampling circuit capable of enabling the circuit to have high linearity, meanwhile, the processing of signal less than the minimum voltage in the circuit can be implemented. The analog signal sampling circuit can generate the constant voltage by arranging the voltage constant module as a voltage between gate source poles when the PMOSFET tube of the switch tube is conductive, the voltage between the grid and the source pole can be kept constant without changing with the variation of the input signal when the PMSFET tube is in the conducting state, the conductive electric resistance of the PMOSFET tube can not change following with the variation of the input signal, at last the PMOSFET has constant conductive electric resistance, the signal distortion through the PMOSFET tube is smaller, the high linearity sampling can be implemented. The invention also provides a switch capacitance circuit.

Owner:BEIJING VIMICRO ARTIFICIAL INTELLIGENCE CHIP TECH CO LTD

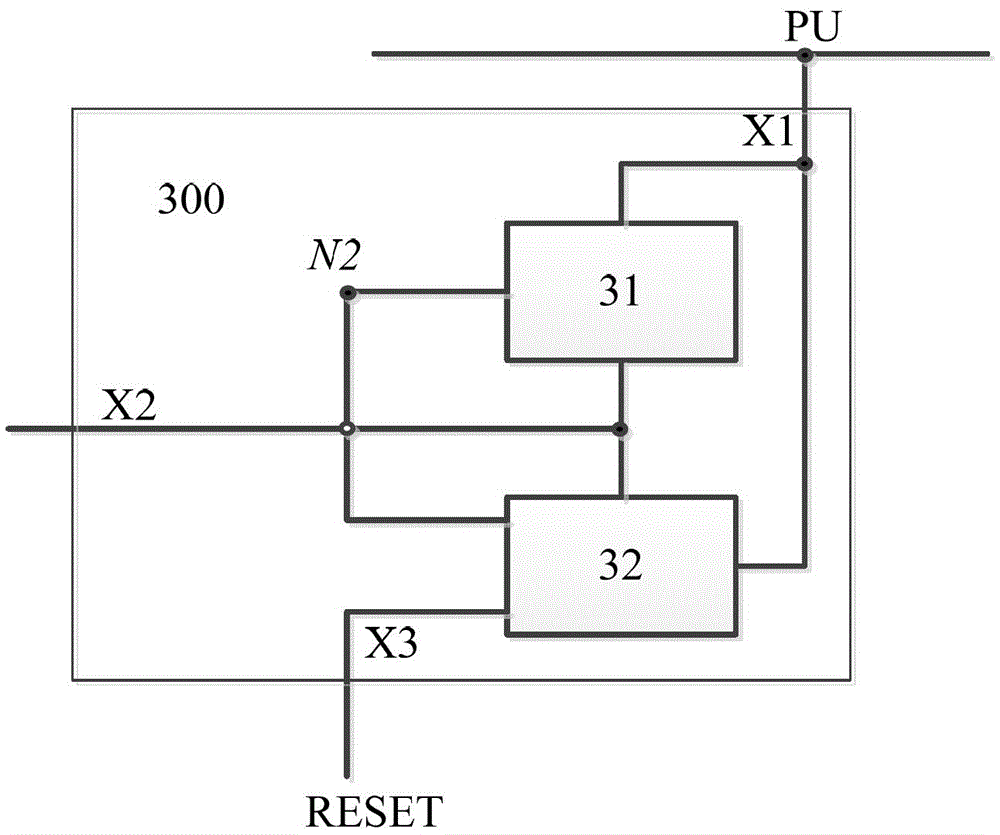

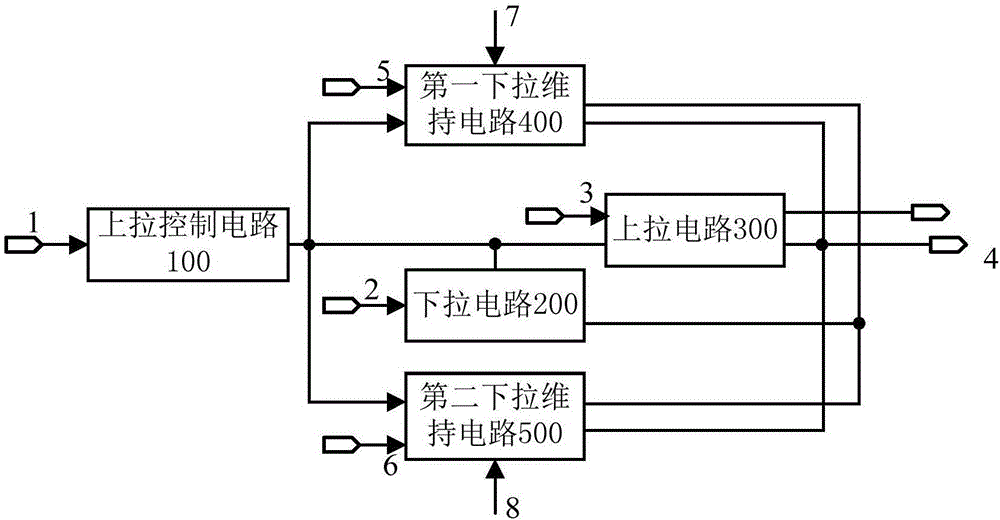

Supplementary reset module, grid driving circuit and display device

ActiveCN105245089APrevent leakageNormal outputStatic indicating devicesDigital storageDriver circuitControl signal

The invention provides a supplementary reset module used for a grid driving circuit. The supplementary reset module comprises a pull-up control unit, a pull-down control unit, a clock signal input end, a predetermined level input end, a first control signal input end, a second control signal input end and a signal output end, wherein a control end of the pull-up control unit is connected with the clock signal input end, an output end of the pull-up control unit is connected with the signal output end of the supplementary reset module, a first control end of the pull-down control unit is connected with the first control signal input end, a second control end of the pull-down control unit is connected with the second control signal input end, an input end of the pull-down control unit is connected with the predetermined level input end, and an output end of the pull-down control unit is connected with the signal output end. The invention further provides the grid driving circuit and the display device. The grid driving circuit provided by the invention can output stable signals.

Owner:BOE TECH GRP CO LTD

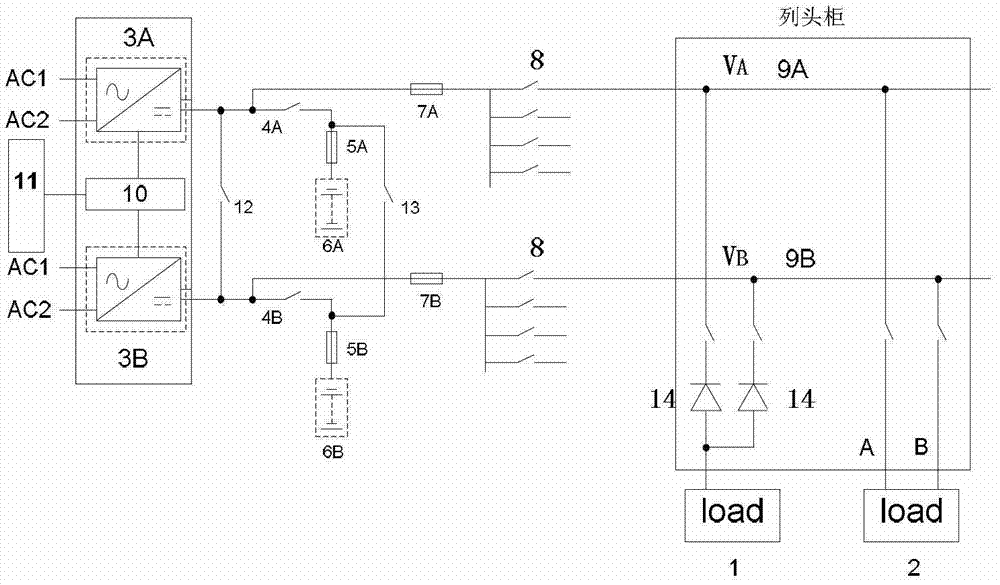

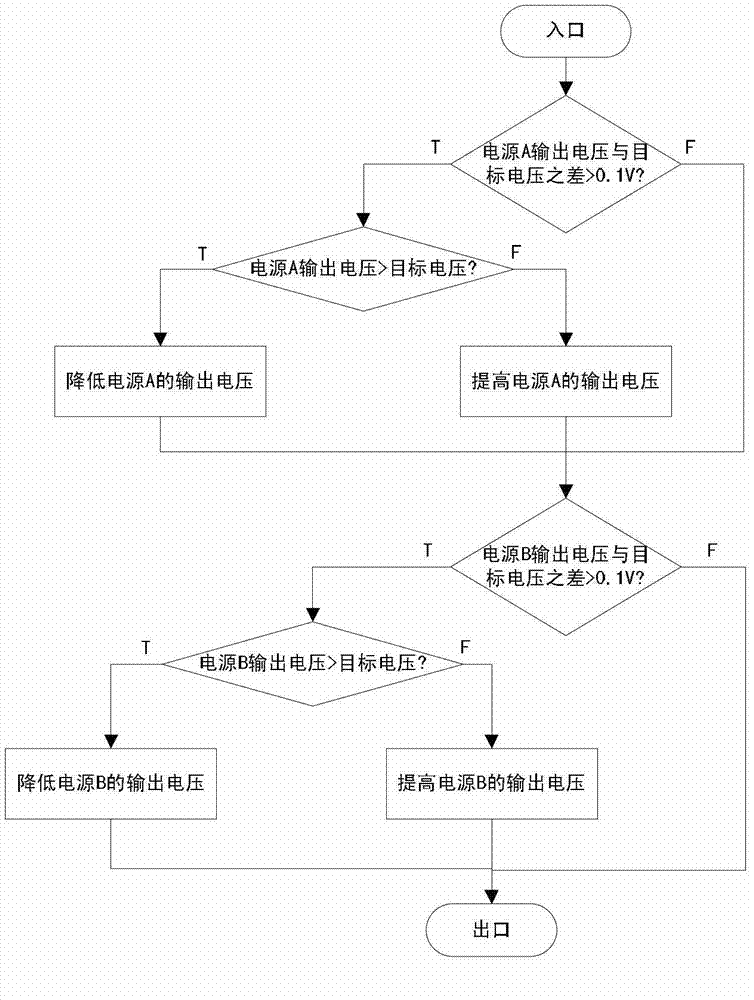

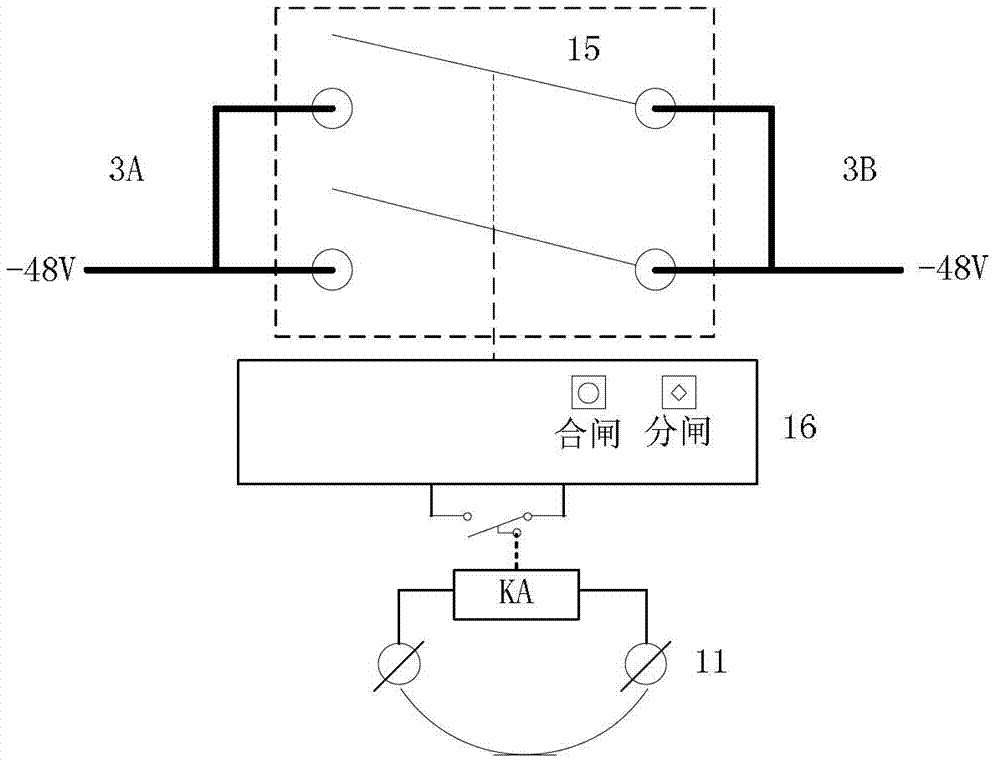

-48V direct current single system double-power-source device and power output control method

InactiveCN103199606AUnlimited output capacityLoad supportBatteries circuit arrangementsElectric powerPower flowEngineering

Owner:HUAXIN CONSULTATING CO LTD

GOA circuit, display panel and display device

The invention provides a GOA circuit, a display panel and a display device, and the GOA circuit comprises: an nth GOA unit which comprises a pull-up control module which is used for pulling up the potential of a first node; a control unit including a control thin film transistor, wherein the drain electrode of the control thin film transistor is connected with the first node, and the source electrode of the pull-up thin film transistor is connected to the n-1th level scanning signal; a voltage stabilizing unit which is used for eliminating the influence of the threshold voltage of the controlthin film transistor on the first node potential, wherein the voltage stabilizing unit is connected with the grid electrode of the control thin film transistor; a pull-up module which is used for pulling up the potential of the output end; a pull-down module which is used for pulling down the potentials of the first node and the output end; and the pull-down maintaining module is used for maintaining the potential of the first node when the first node is at a low potential. According to the GOA circuit, the display panel and the display device, the high potential of the Q point can reach the preset value, and the situation that the GOA circuit cannot normally output is avoided.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

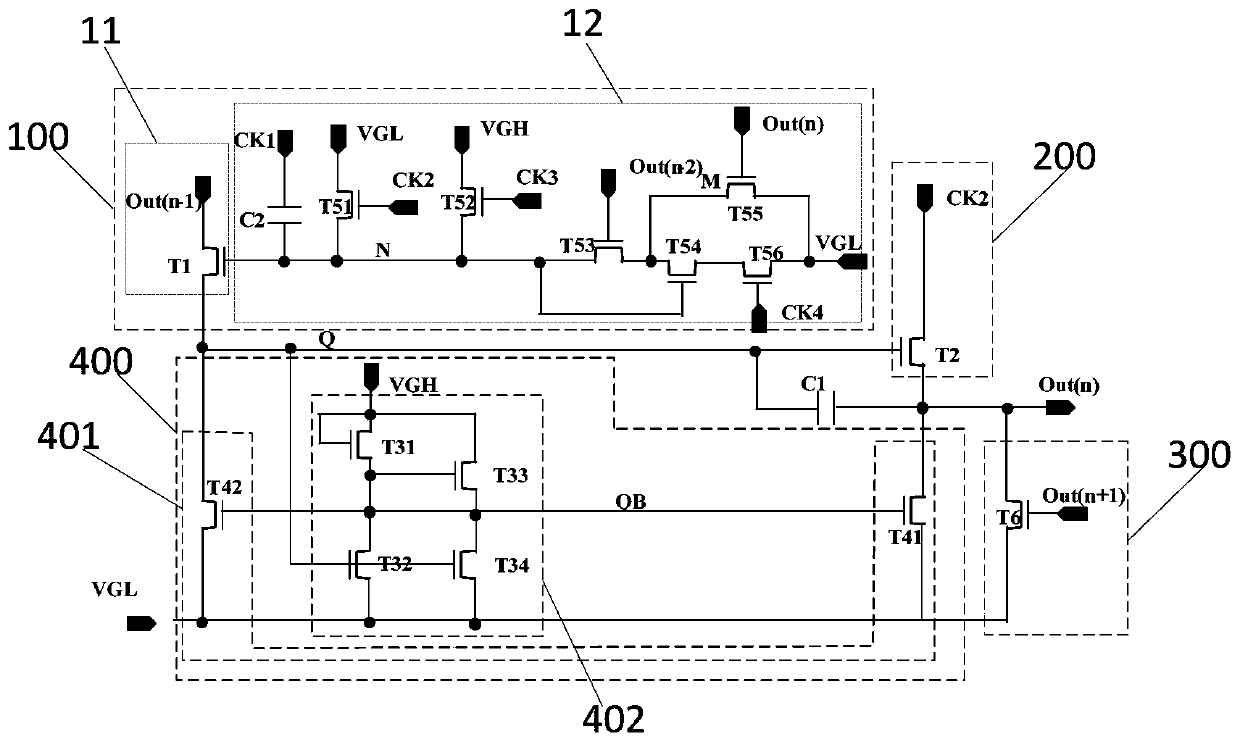

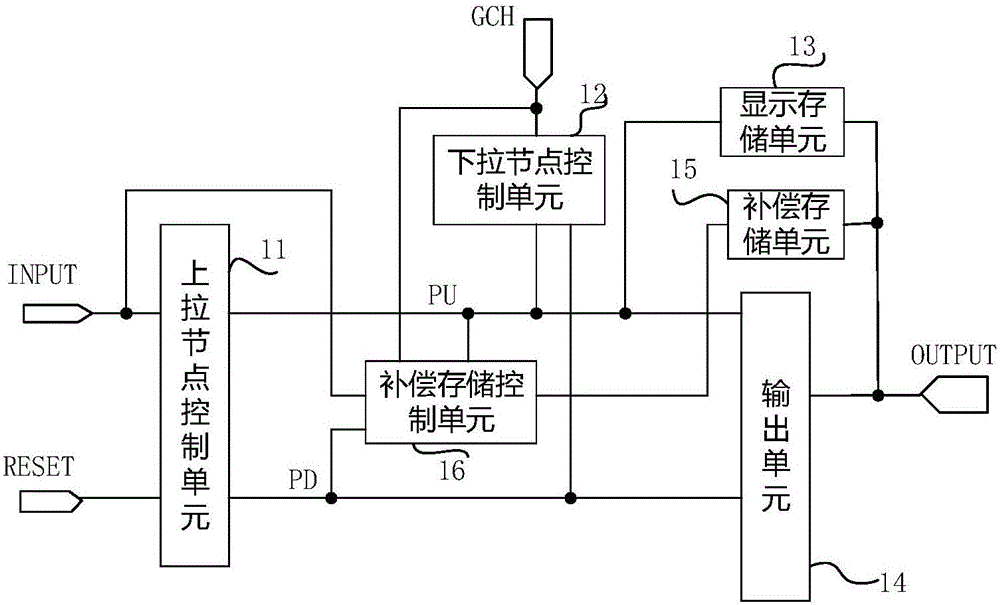

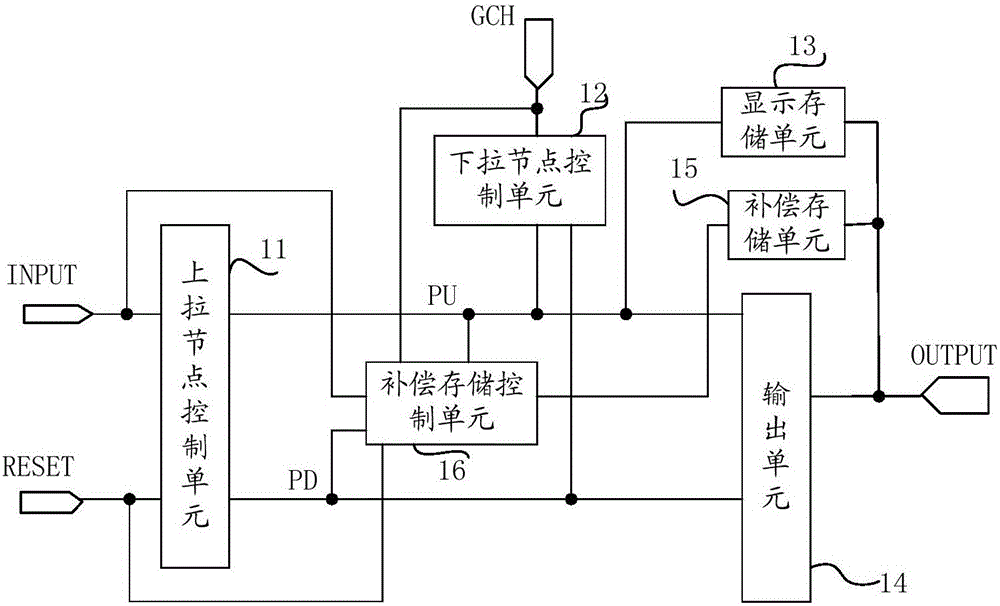

Gate drive circuit, gate drive method and display device

The invention provides a gate drive circuit, a gate drive method and a display device. The gate drive circuit comprises a pull-up node control unit, a pull-down node control unit, a display and storage unit and an output unit. The gate drive circuit also comprises a compensation and storage unit and a compensation and storage control unit. The compensation and storage control unit is connected with an input end, a pull-down control voltage end, a pull-up node, a pull-down node and the second end of the compensation and storage unit and used for controlling the pull-down control voltage end to be connected with the second end of the compensation and storage unit in the input phase under the control of the input end so as to charge the compensation and storage unit and also used for controlling the second end of the compensation and storage unit to be connected with the pull-up node in the output phase when the potential of the pull-down node is high level. The problem that the existing gate drive circuit has no gate drive signal output can be solved by the gate drive circuit, the gate drive method and the display device.

Owner:HEFEI BOE OPTOELECTRONICS TECH +1

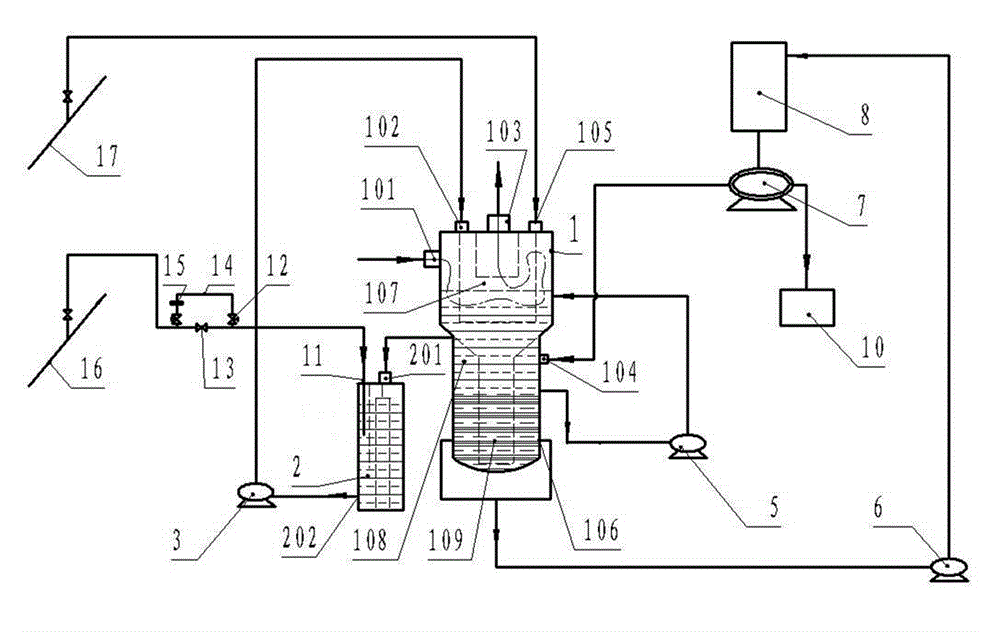

Production method of ammonium sulfate

The invention discloses a production method of ammonium sulfate, which comprises the following steps: A, reacting coke oven gas and ammonia gas with a sulfuric acid solution in a spray area of a saturator so as to obtain a product a; B, guiding aqueous ammonia into an overflow tank to react with a sulfuric acid solution so as to obtain a product b, and conveying the product b to the inside of the saturator by a small mother liquor circulating pump to react with the sprayed sulfuric acid solution in the spray area of the saturator, so that a product c is obtained; C, feeding the product a and the product c into a crystallization area of the saturator, so that ammonium sulfate in the product a and the product c is gradually crystallized and separated out; D, conveying ammonium sulfate-containing crystallizing liquid to the inside of a crystallizing elevated tank from a crystallizing liquid outlet by a crystallizing pump; and E, conveying the crystallizing liquid in the crystallizing elevated tank to a centrifugal machine to separate, and conveying precipitates obtained by separating to a dryer to dry, so that ammonium sulfate is obtained. According to the invention, an ammonium sulfate product is produced by taking aqueous ammonia produced in the process of ammonia washing implemented by using phosphoric acid as a raw material, so that the problem that aqueous ammonia produced in the process of ammonia washing implemented by using phosphoric acid is surplus is solved.

Owner:LIUZHOU IRON & STEEL

Low power consumption analogue signal sample retaining circuit and its application method

InactiveCN1428932AReduce power consumptionNormal outputElectronic switchingPhysical realisationEngineeringControl switch

The present invention relates to an analog signal sampling / holding circuit with low power consumption and its application method. Said invention includes at least three-stage amplification circuit, sampling and holding circuit, and it is characterized by that three control switches are added, and a control signal is newly added, and can be used for respectively controlling the described control switches, and the last one-stage amplification circuit input end can be used for controlling control signal inversion of switch and other control switches. When the neural operation amplification sampling / holding circuit is in the rest state, the power consumption of the circuit only is formed from electric leakage of tube, so that it possesses the advantages of low power consumption, and when the circuit is in the restoration state, its sampling signal can be normally outputted.

Owner:BEIJING LHWT MICROELECTRONICS

Method for regenerating aluminum electrolysis bath carbon waste into alternative fire coal

ActiveCN107363074AThe output is equivalentNormal outputSolid waste disposalSolid fuelsElectrolysisCatalytic oxidation

A method for regenerating aluminum electrolysis bath carbon waste into alternative fire coal comprises the following steps that (1) conducting pelletization and detoxication, wherein the aluminum electrolysis bath carbon waste is crushed, a detoxicating agent solution is atomized and sprayed, and then pelletized detoxicated materials are obtained; (2) conducting activation, wherein a catalytic oxidant is added, homogenizing and modifying are conducted, and then the alternative fire coal is obtained; or, the catalytic oxidant and lime are added, water is added, stirring is conducted or rolling mixing is conducted, oxidation alkaline removal are conducted, filtering or filtering and washing are conducted, drying is conducted, and then the alternative fire coal is obtained; or, the catalytic oxidant, lime and sodium hydroxide are added, water is added, stirring is conducted or rolling mixing is conducted, oxidation aluminum removal and alkaline removal are conducted, filtering or filtering and washing are conducted, drying is conducted, and then the alternative fire coal is obtained; or, supercritical or liquid-state carbon dioxide is adopted for leaching processing, the catalytic oxidant is added to carbon dry powder for homogenizing and modifying, and then the alternative fire coal is obtained. The calorific value of the regenerated alternative fire coal is equal to that of semibituminous coal and anthracite and is about 5000 kcal / kg on average, and the regenerated alternative fire coal can be used as alternative fire coal; and the method is simple in technology, low in energy consumption and cost and suitable for industrialized production.

Owner:长沙紫宸科技开发有限公司

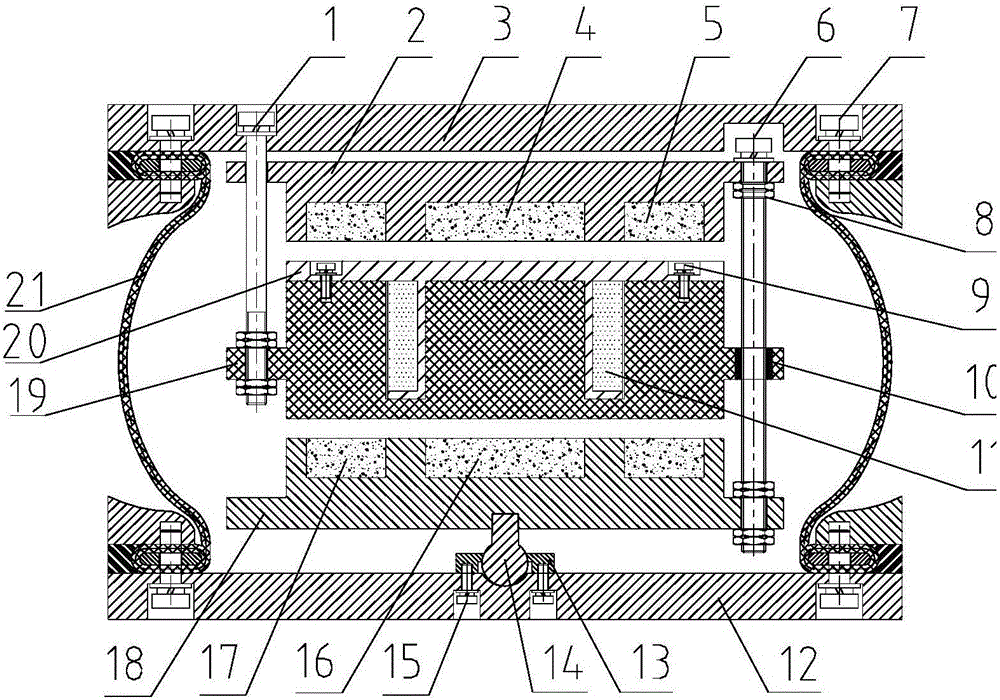

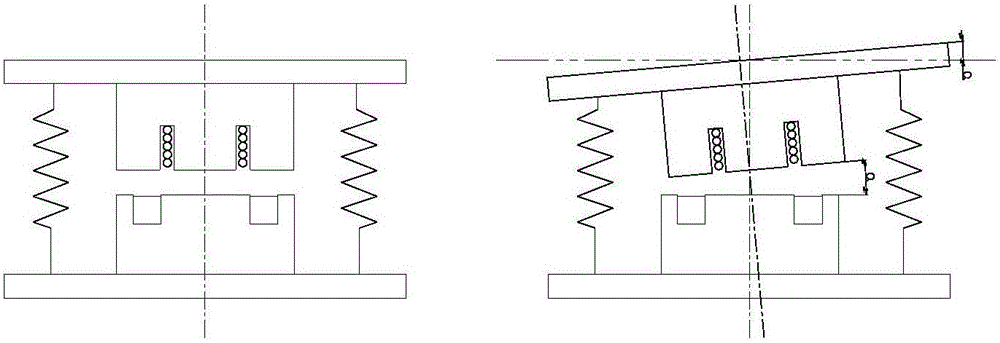

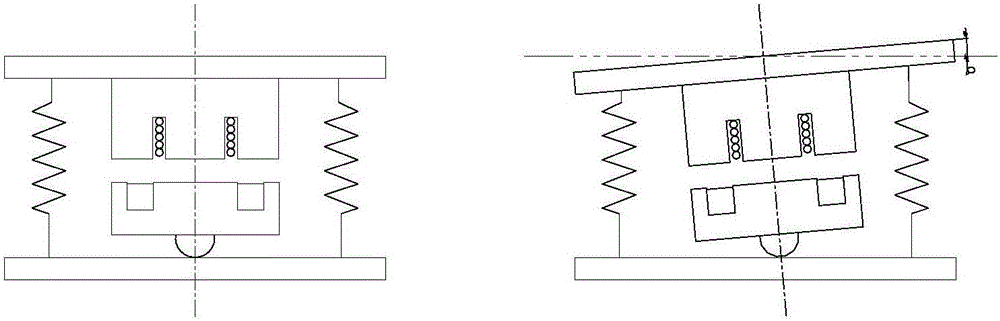

Swing-resistant electromagnetic hybrid active actuation mechanism

InactiveCN105927701ASuppression of medium and high frequency vibrationAvoid stuck phenomenonPivotal connectionsVibration suppression adjustmentsNoise controlElectricity

The invention belongs to the technical field of vibration noise control, and particularly relates to a vibration active control technology. According to the technical scheme of a swing-resistant electromagnetic hybrid active actuation mechanism, a passive vibration isolator is composed of an upper cover plate, an airbag damper bag body, a lower cover plate and shell locking bolts and is used for suppressing medium-high frequency vibration of a controlled object; an active actuation mechanism body is composed of an upper armature, a middle armature, a lower armature, circular permanent magnets, annular permanent magnets, coil windings, a coil retainer, a middle screw, a fixing screw and a linear bearing; The permanent magnets and the armatures form a magnetic channel; current coils cut magnetic lines of force in the magnetic channel to generate electromagnetic force; and the distance between the upper permanent magnet and the coil windings is equal to the distance between the lower permanent magnet and the coil windings, so that it is ensured that the average magnetic field strength in the coils of the middle armature driven by the electromagnetic force is consistent, the magnitude of output force does not change with changes of strokes of the middle armature, and nonlinearity is avoided. It is ensured that the output force of the active actuation mechanism is normal when controlled equipment inclines or swings, and the stuck stagnation phenomenon of a conventional actuation mechanism is avoided.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

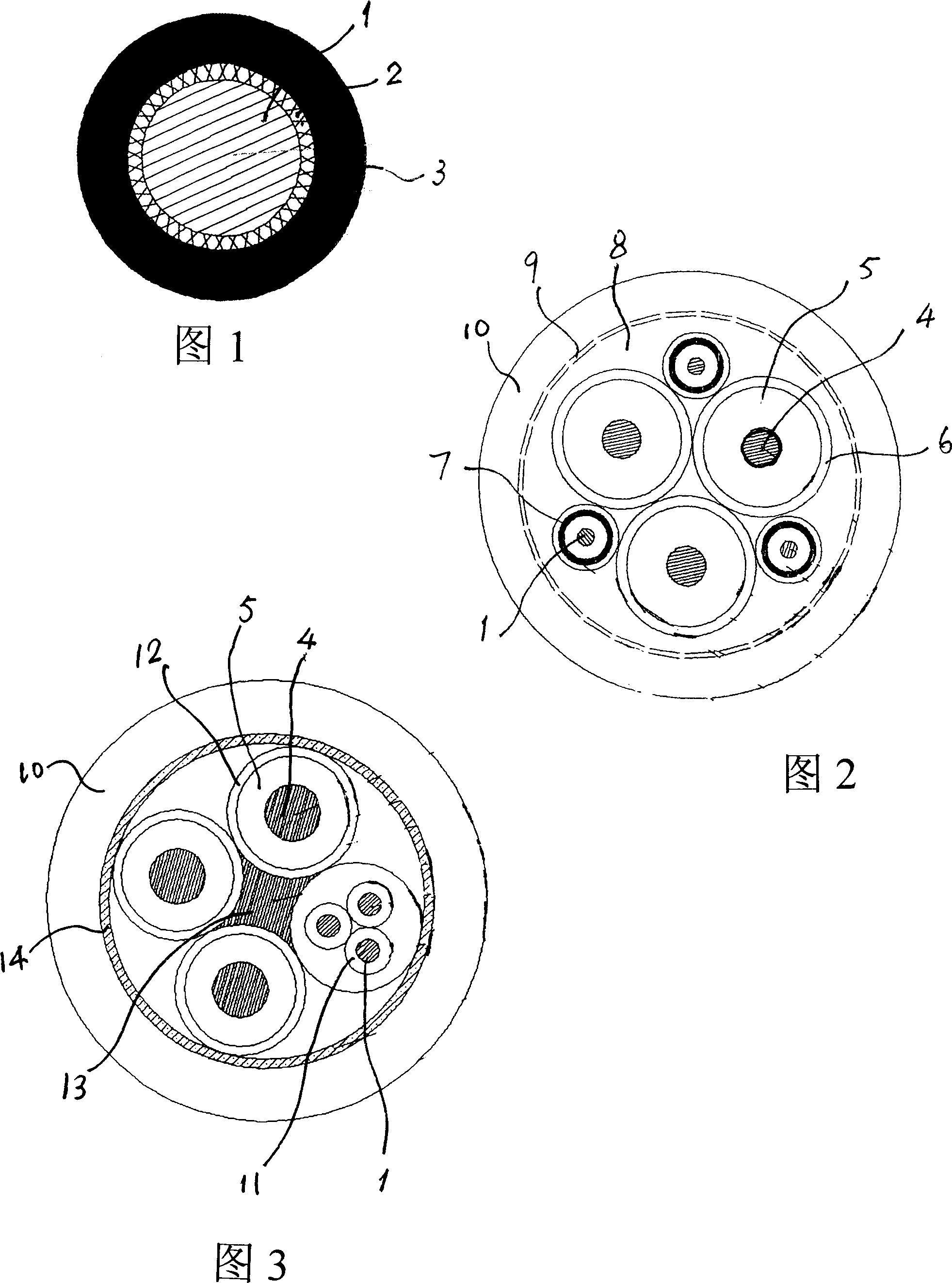

Electric cable for coal mining machine

InactiveCN1909117AImprove bending resistanceImprove tensile propertiesRubber insulatorsPlastic/resin/waxes insulatorsCopper conductorPolyester

The invention relates to a coal machine cable, which is formed by three copper conductive wire cores (4); insulate layer, control wire core (1) and rubber muffle, wherein the control wire core (1) is covered by insulated layer while the middle is polyester band; the control wire core (1) uses composite structure, whose center is beamed and screwed into screw copper conductor; the outer layer is high-carbon steel weave layer (2), and packed with ethylen-propylene rubber insulated layer (3); the control wire core (1) and three copper wire cores (4) form cable core; said cable core is packed with muffle (10); since it uses high-carbon steel weave layer, the anti-bend ability and anti-drawing ability of control wire core are improved, to avoid breakage.

Owner:QINGDAO HANHE CABLE

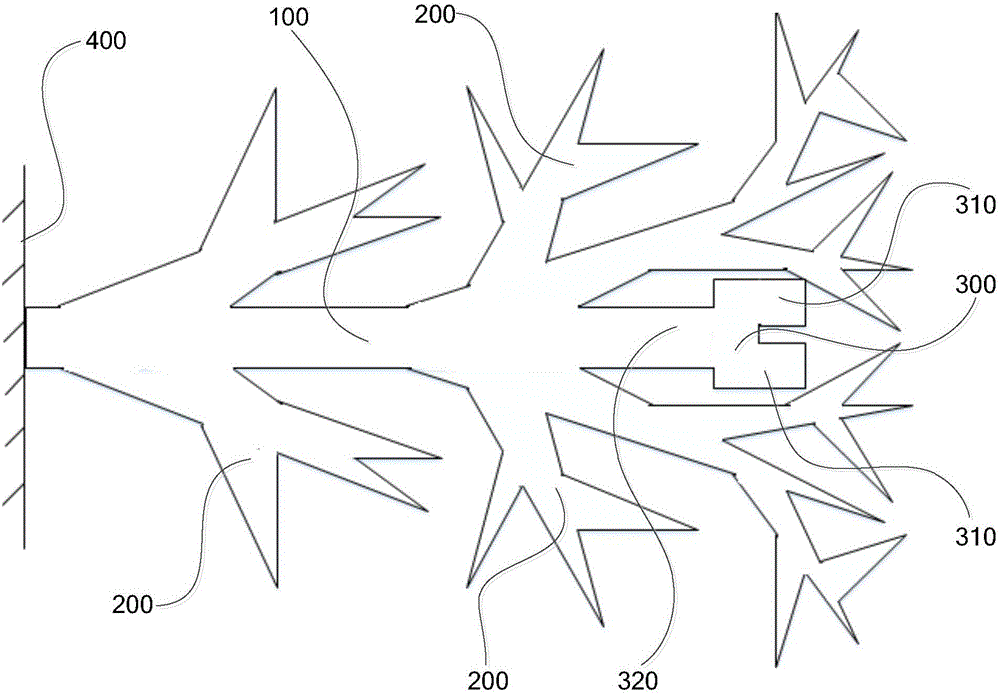

Piezoelectric energy collector and power generation equipment

InactiveCN107181427AImprove collection efficiencyImprove conversion efficiencyPiezoelectric/electrostriction/magnetostriction machinesFrequency bandElectricity

The present invention relates to a piezoelectric energy collector. The piezoelectric energy collector comprises piezoelectric plates which are used for generating a piezoelectric effect and comprise first piezoelectric plates and second piezoelectric plates, a multi-arm beam which comprises a main beam and a plurality of support beams arranged on the main beam, and a mass block, wherein one end of the main beam is fixedly arranged, the first piezoelectric plate is arranged on the main beam, the second piezoelectric plate is arranged on the support beams, the mass block is arranged at the other end of the main beam, and the mass block and the support beams are arranged in a staggered way. Through the setting of the main beam and the support beams, the main beam and the support beams have different vibration frequencies respectively, when vibration happens, the main beam and the support beams are matched with different vibration frequencies, thus the resonant frequency points of a whole system are increased, the frequency band is broadened, problems of a single working frequency and a narrow frequency band of a traditional piezoelectric energy collector are solved, the natural frequency of the main beam can be reduced through the setting of the mass block, thus the multi-arm beam and an environment vibration source reach a resonant state as soon as possible, generated voltage is larger, and the acquisition and conversion efficiency of the piezoelectric energy collector are improved.

Owner:SYSU CMU SHUNDE INT JOINT RES INST +1

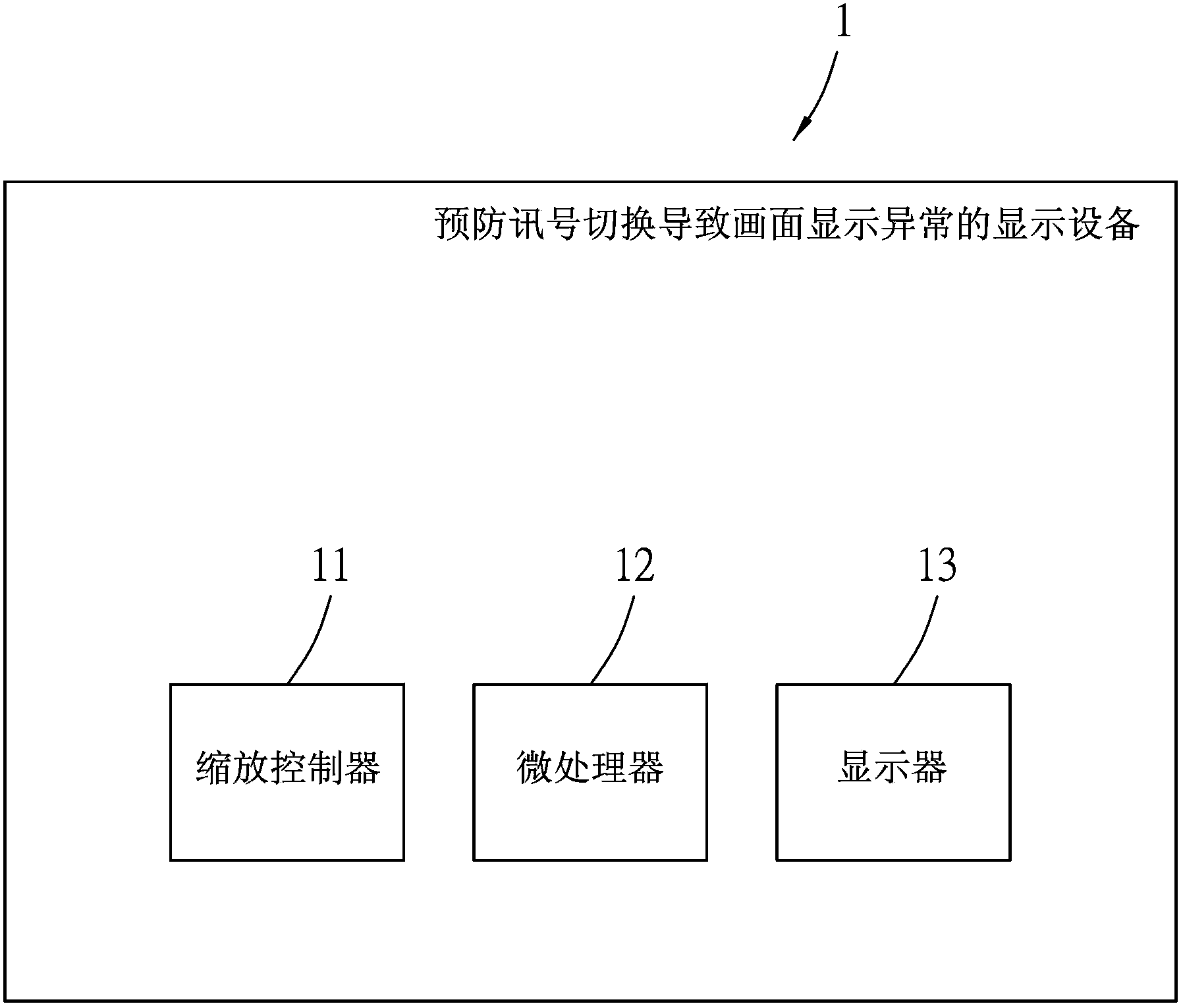

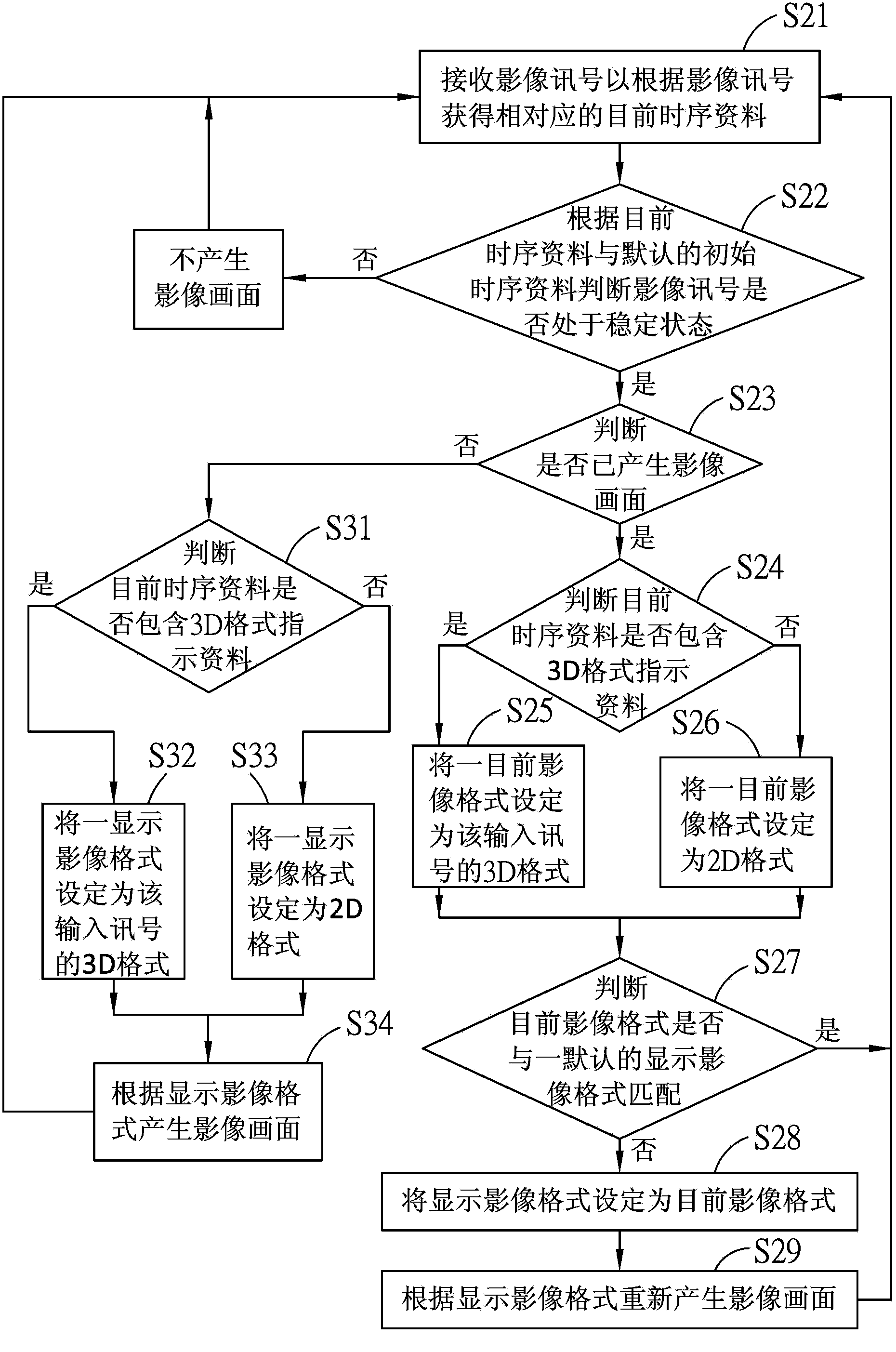

Display method and equipment capable of preventing abnormal image display caused by signal switchover

InactiveCN103544932ANormal outputCathode-ray tube indicatorsSteroscopic systemsStable stateComputer graphics (images)

Disclosed are a display method and equipment capable of preventing abnormal image display caused by signal switchover. The display method includes steps of receiving an image signal to acquire current time sequence data; judging whether the image signal is stable or not according to the current time sequence data and initial time sequence data; judging whether an image is generated or not if the image signal is stable; judging whether the current time sequence data include 3D (three dimensional) format indicating data or not if the image is generated; setting a current image format as the 3D format of an input signal if the 3D format indicating data are included; judging whether the current image format is matched with a display image format or not; if not, setting the display image format as the current image format; and repeatedly generating the image. The image can be normally outputted and displayed without repeatedly pulling and plugging a connector of a high-definition multimedia interface or restarting a display by users.

Owner:TOP VICTORY INVESTMENTS

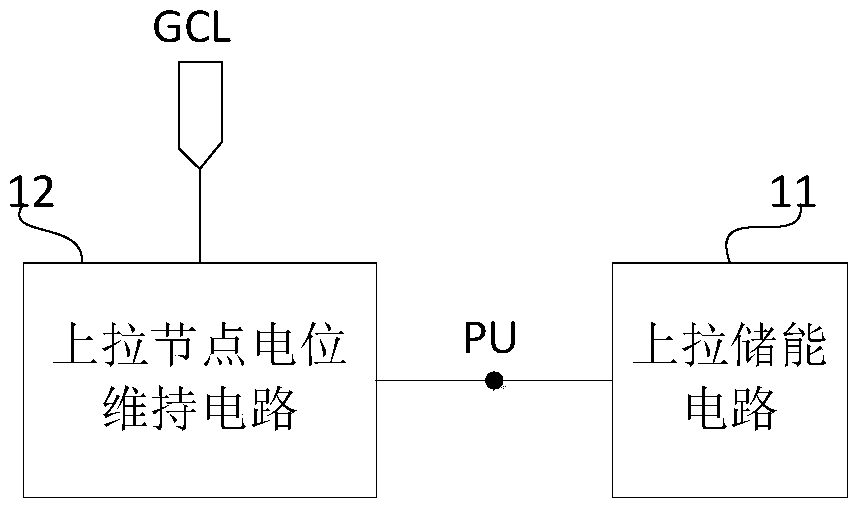

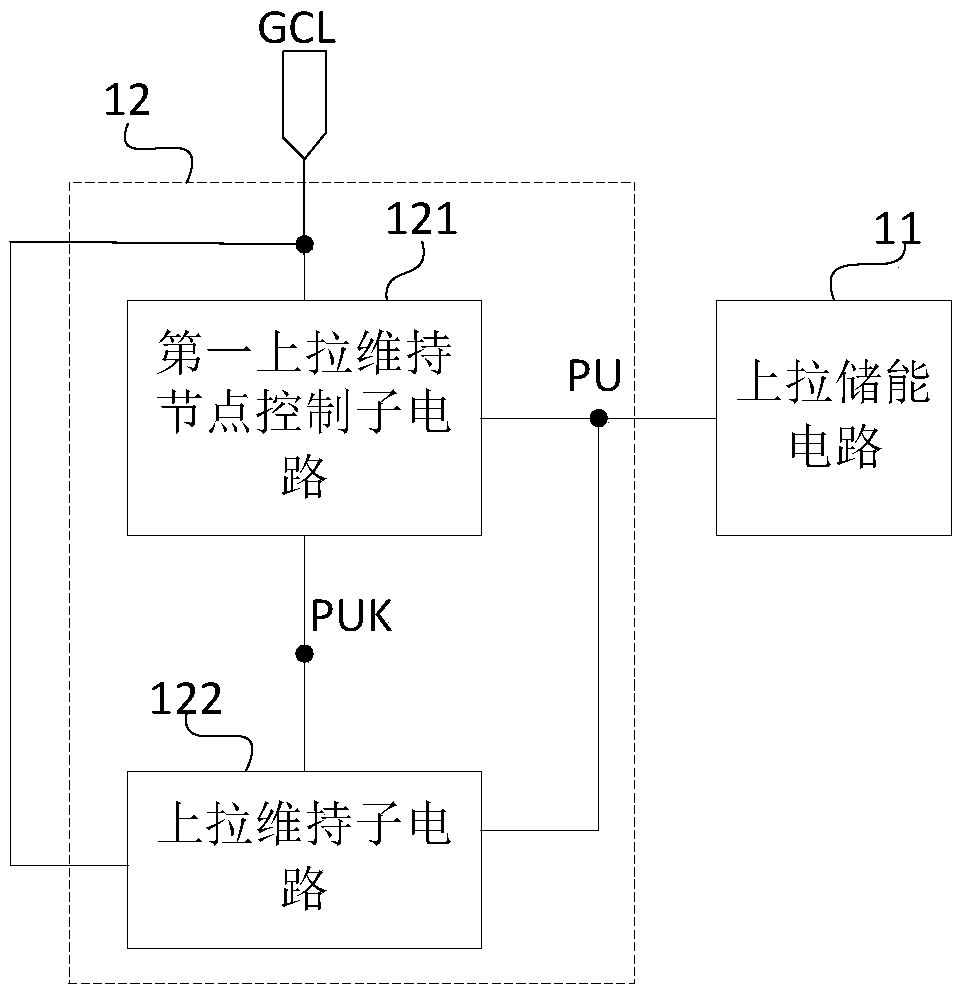

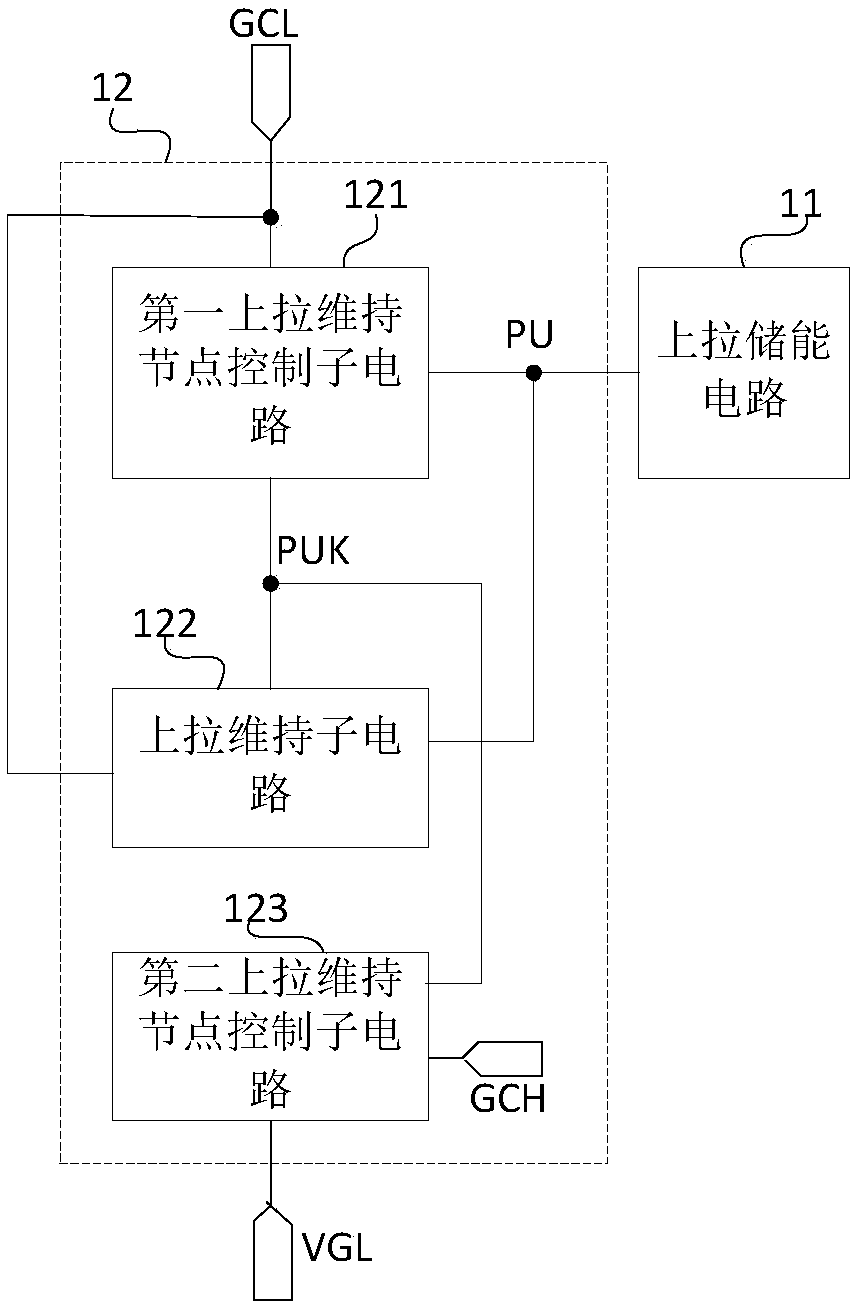

Shift register unit, driving method and display device

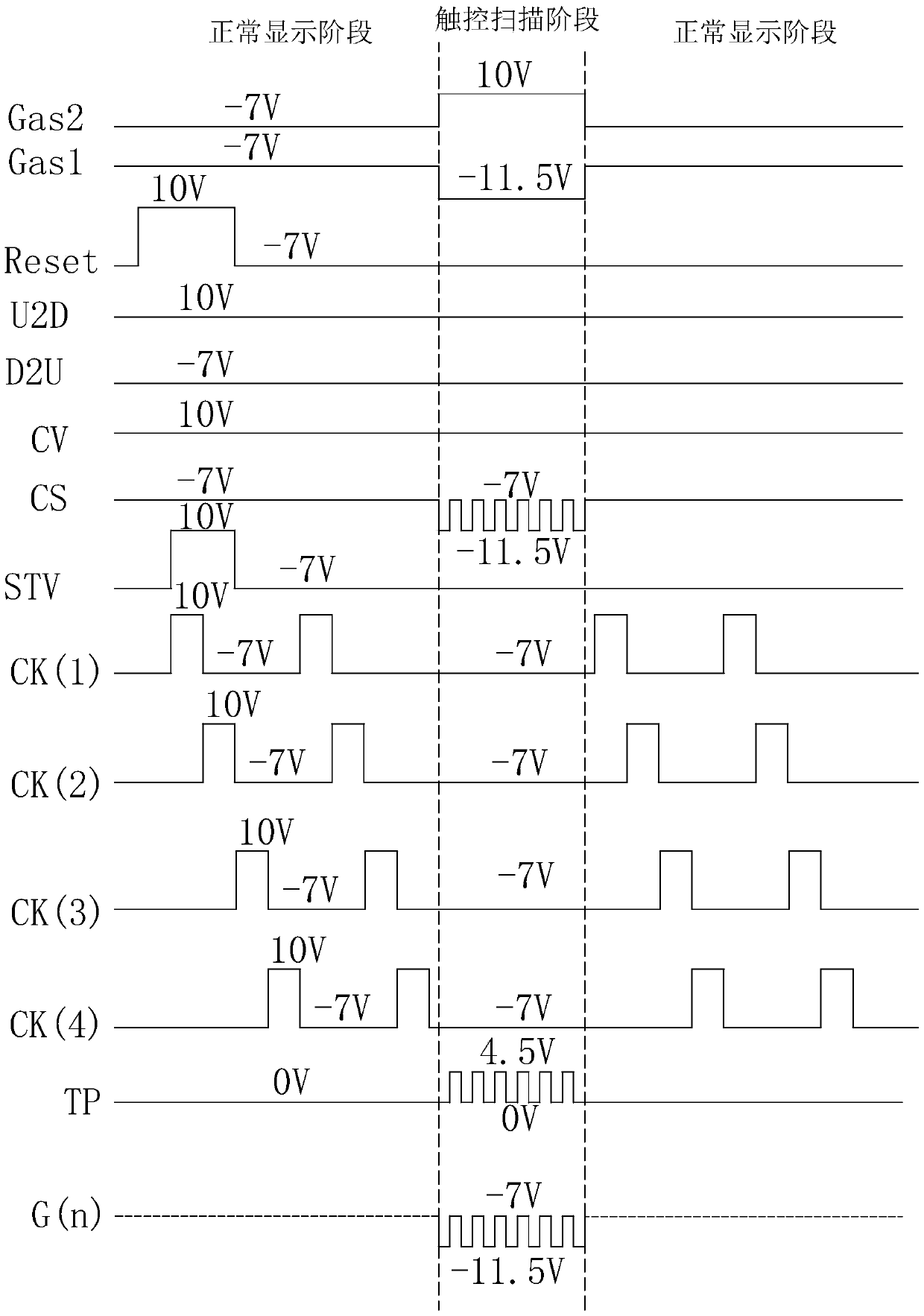

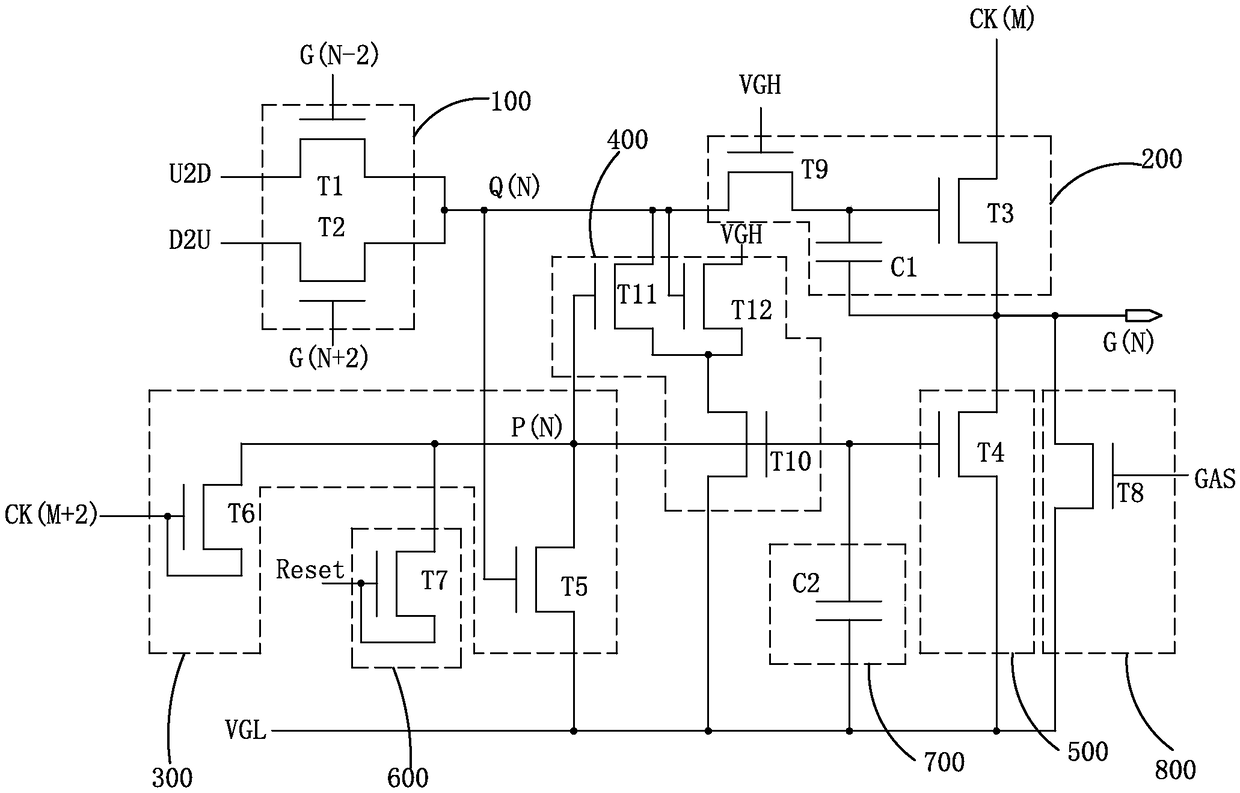

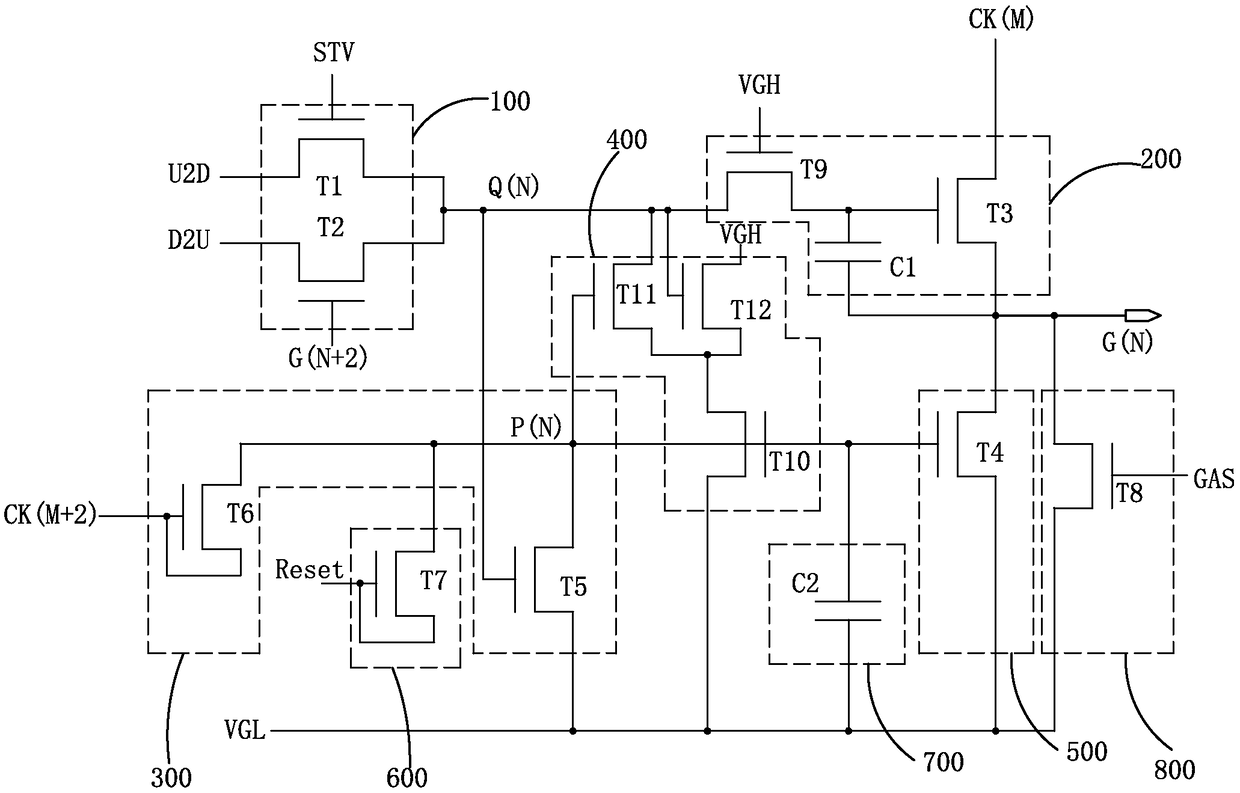

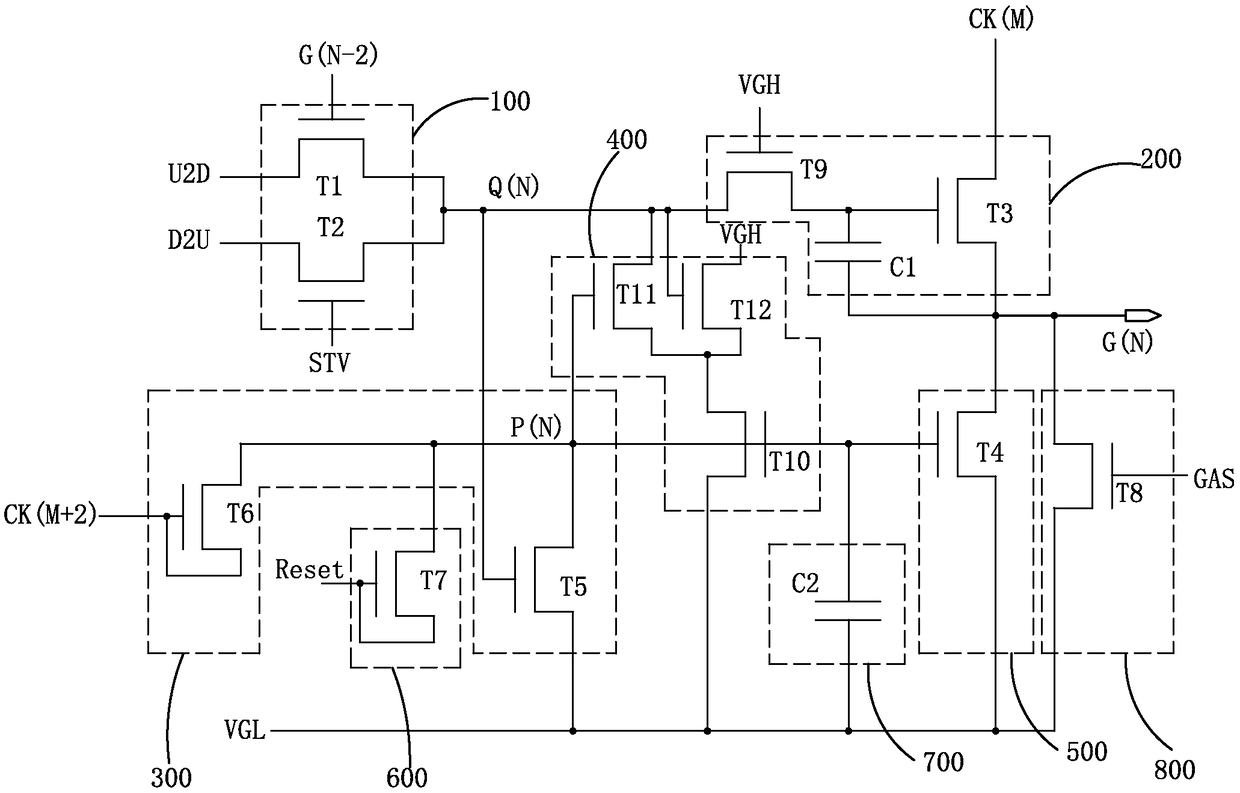

The invention provides a shift register unit, a driving method and a display device. The shift register unit comprises a pull-up energy storage circuit and a pull-up node potential maintaining circuit, wherein the pull-up energy storage circuit is connected with a pull-up node; the pull-up node potential maintaining circuit is separately connected with the pull-up node and a first voltage end andused for charging the pull-up energy storage circuit through a first voltage signal input by the first voltage end to maintain the potential of the pull-up node at an effective level when the potential of the pull-up node is at the effective level in a touch control stage. According to the shift register unit, the potential of the pull-up node can be maintained at the effective level in the touchcontrol stage, and therefore when entering a next display stage after the touch control stage is finished, the shift register unit can normally output a grid drive signal.

Owner:BOE TECH GRP CO LTD +1

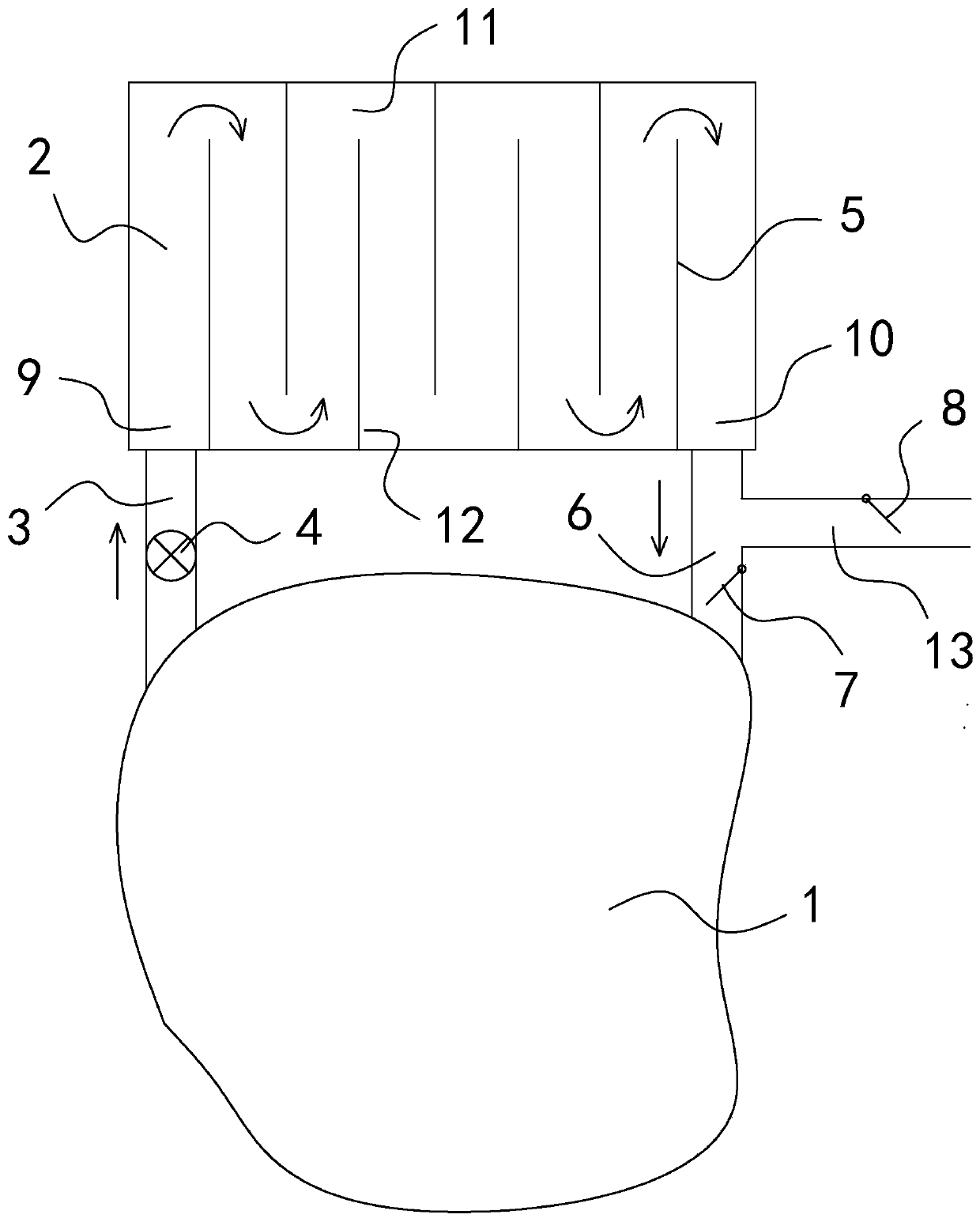

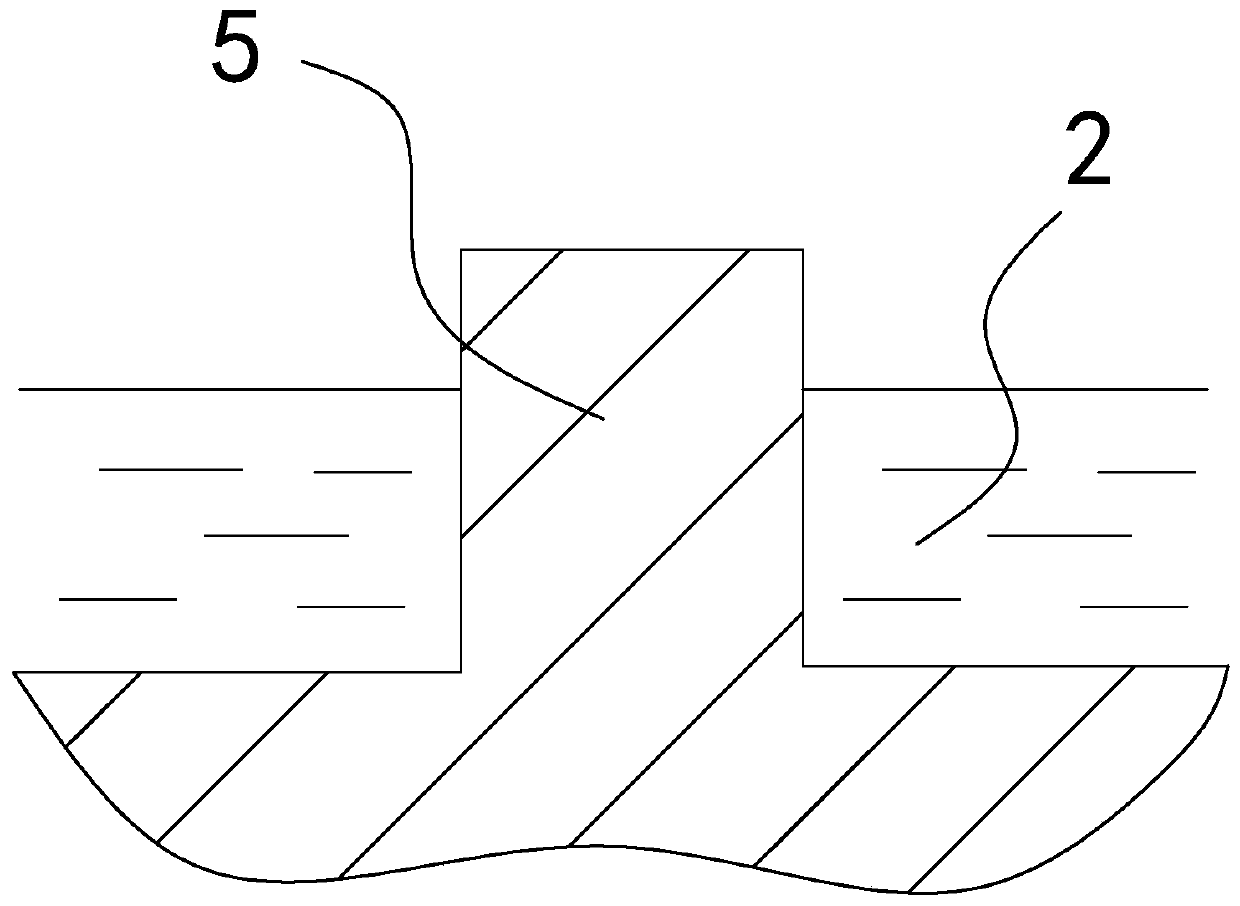

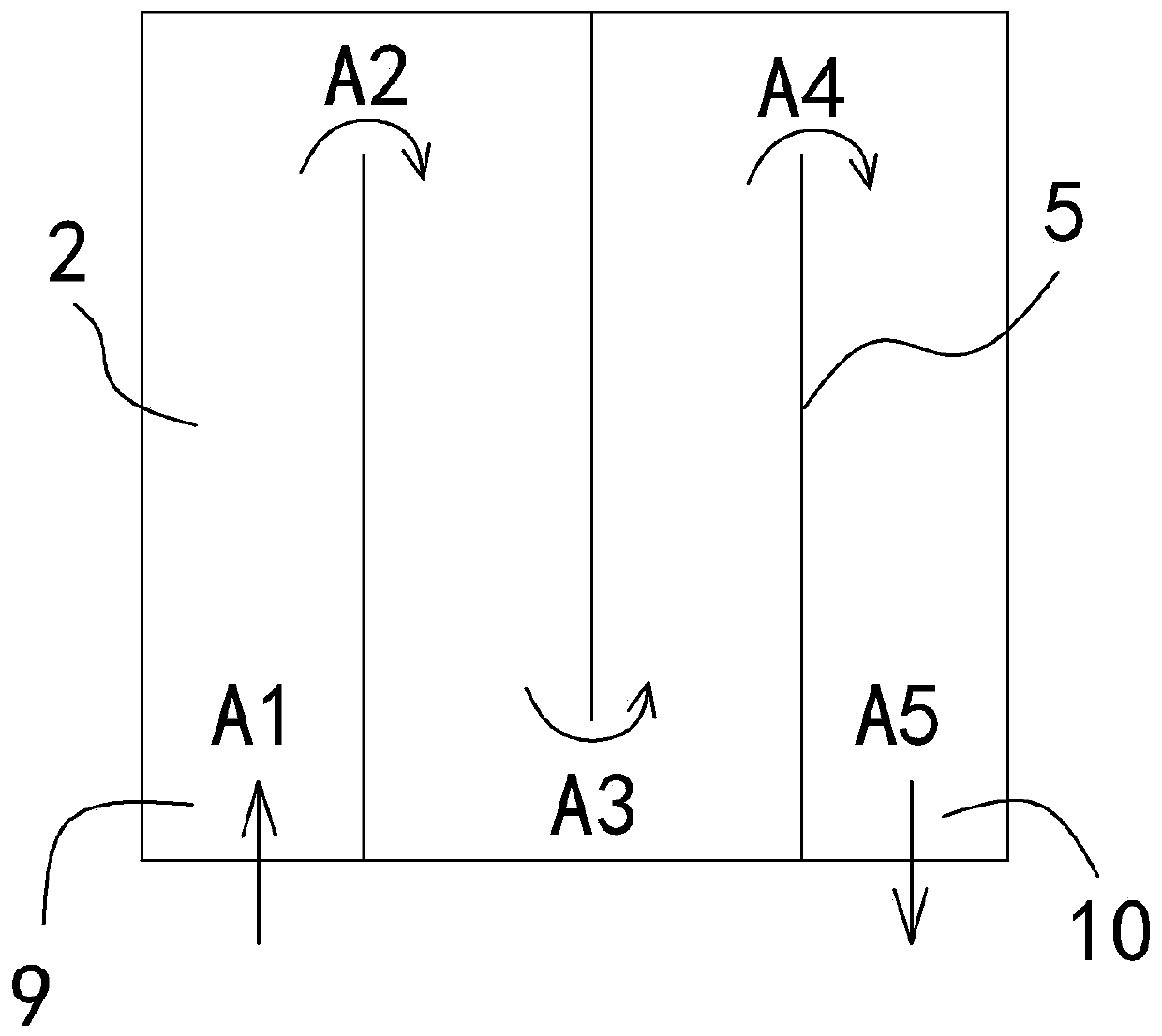

Ecological composite breeding system with cooperation of fishing and rice

PendingCN111066714AProtect environmentReduce total nitrogenPisciculture and aquariaRice cultivationChemical oxygen demandZoology

The invention discloses an ecological composite breeding system with cooperation of fishing and rice. A fish pond is positioned in one side of a rice field; a first water channel is formed from the fish pond to the rice field; and a second water channel is formed from the rice field to the fish pond. The system is characterized in that the configuration ratio of the area of the fish pond to the area of the rice field is 20:1 to 35:1. Small ridges are constructed in the rice field, and the small ridges form an "S"-shaped water flow routes from a water inlet end to a water outlet end in the ricefield. When the water level of the fish pond is lower than that of the rice field, a water pump is arranged in the first water channel, and a first gate is arranged in the second water channel; and when the water level of the fish pond is higher than that of the rice field, the first gate is arranged in the first water channel, and the water pump is arranged in the second water channel. By adopting the scheme, the function that nitrogen, phosphorus and other eutrophy substances are effectively absorbed in the growth process of the rice field is sufficiently taken into play, pollutants such astotal nitrogen, total phosphorus, ammoniacal nitrogen, nitrate nitrogen and CODs (chemical oxygen demands) which are discharged into the environment can be also effectively reduced, and meanwhile, anormal yield of rice can be achieved under a condition that fertilization is reduced.

Owner:SUZHOU ACADEMY OF AGRI SCI

Reset circuit, drive method thereof, shifting register unit and grid scanning circuit

ActiveCN105589604AReset normalRealize resetStatic indicating devicesDigital storageElectricityShift register

The invention relates to a reset circuit, a drive method thereof, a shifting register unit and a grid scanning circuit. The reset circuit comprises a reset unit, a reset control unit and multiple access ends; the reset unit is applicable to be started so as to switch on a second access end and a first access end when the voltage of a second node is a first electric level; the reset unit is applicable for switching on the second access end and a second node when the voltage of the first access end is the first electric level; when the voltage of the second access end is a second electric level, the second anode and a third access end are switched on. In the scanning stage of the shifting register unit comprising the reset circuit provided by the invention, the first node can be reset normally; in the scanning interruption stage, the first node is maintained at the first electric level; and therefore, the shifting register unit can normally output signals after recovery scanning.

Owner:BOE TECH GRP CO LTD +1

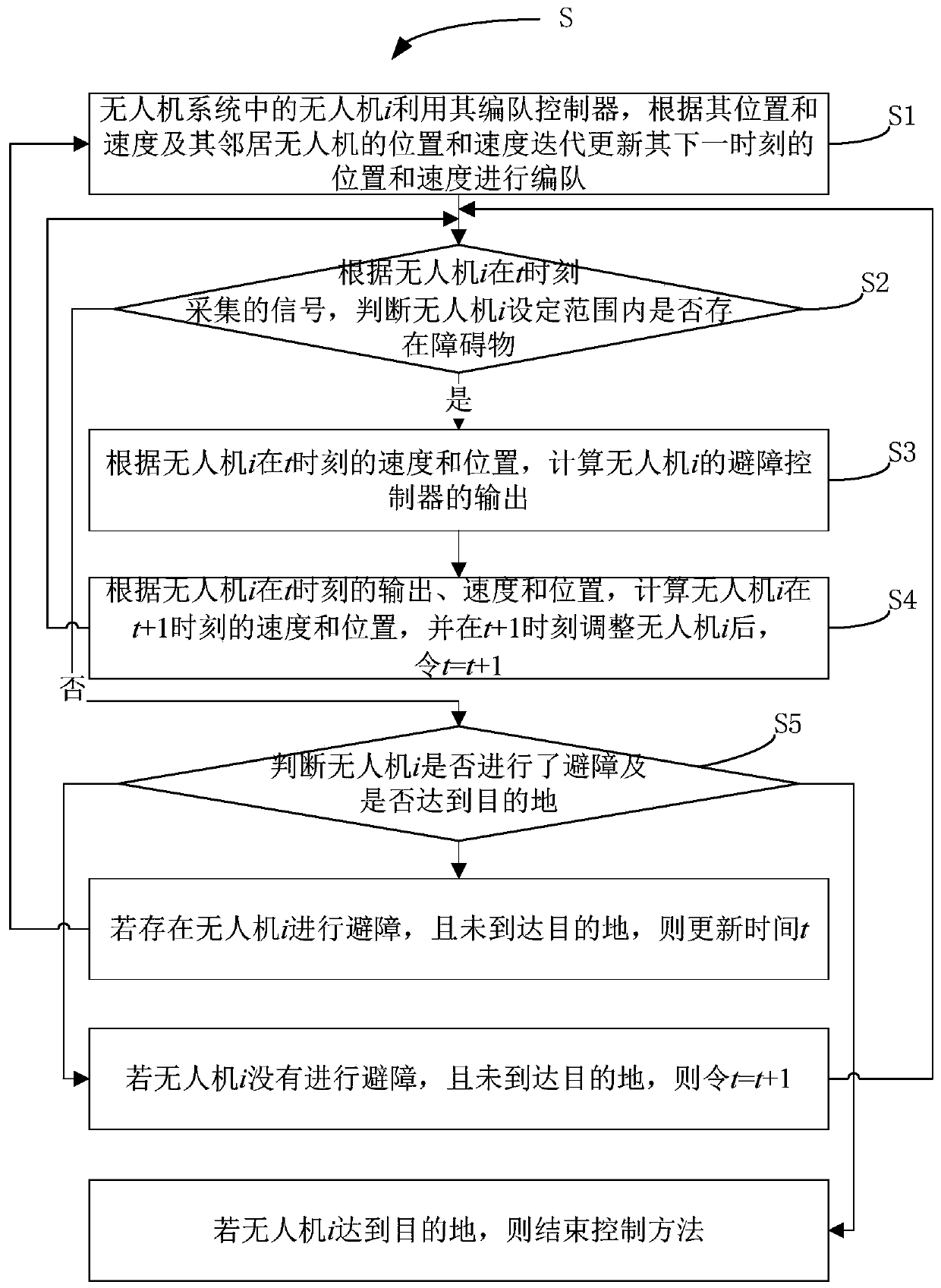

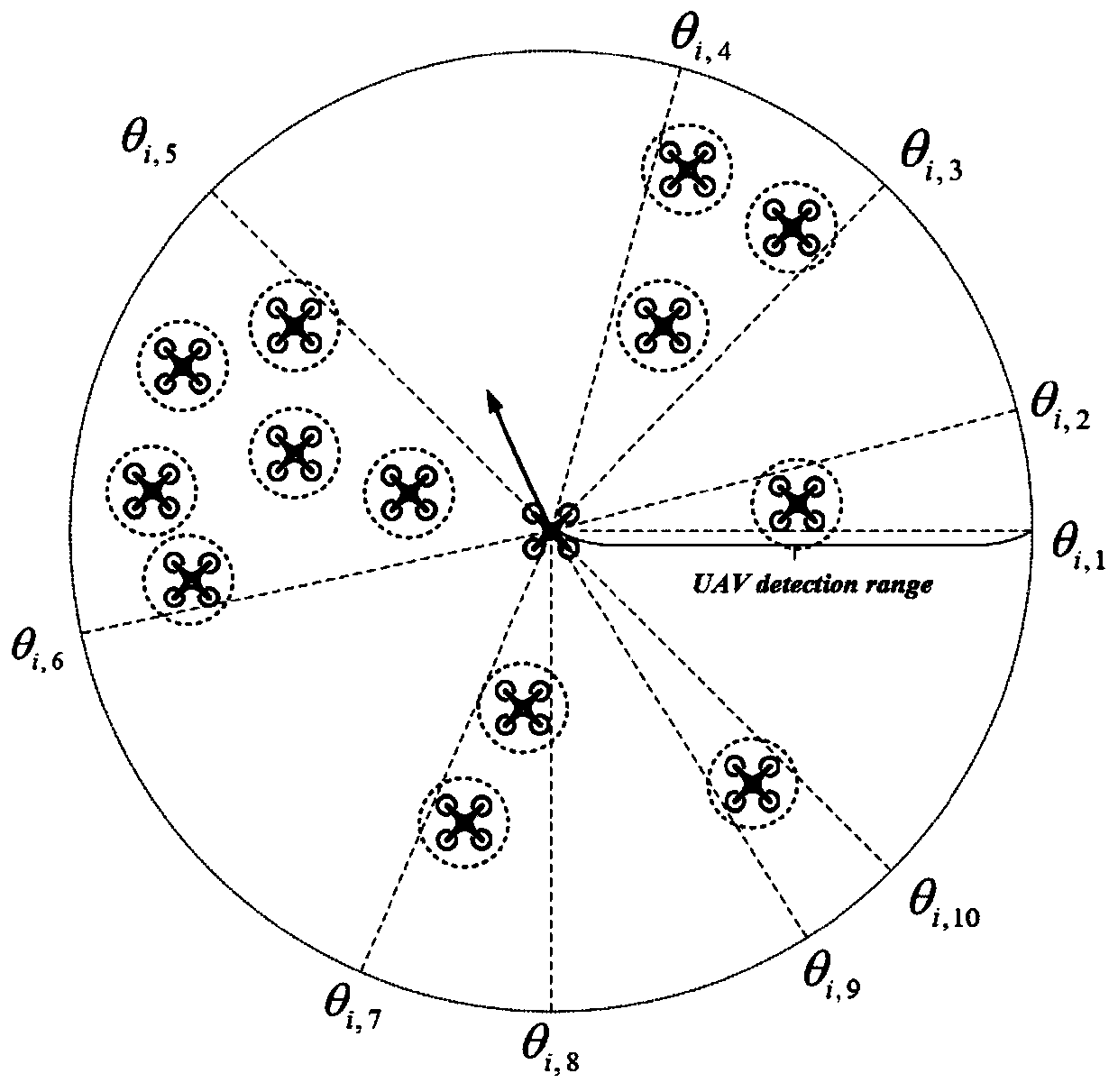

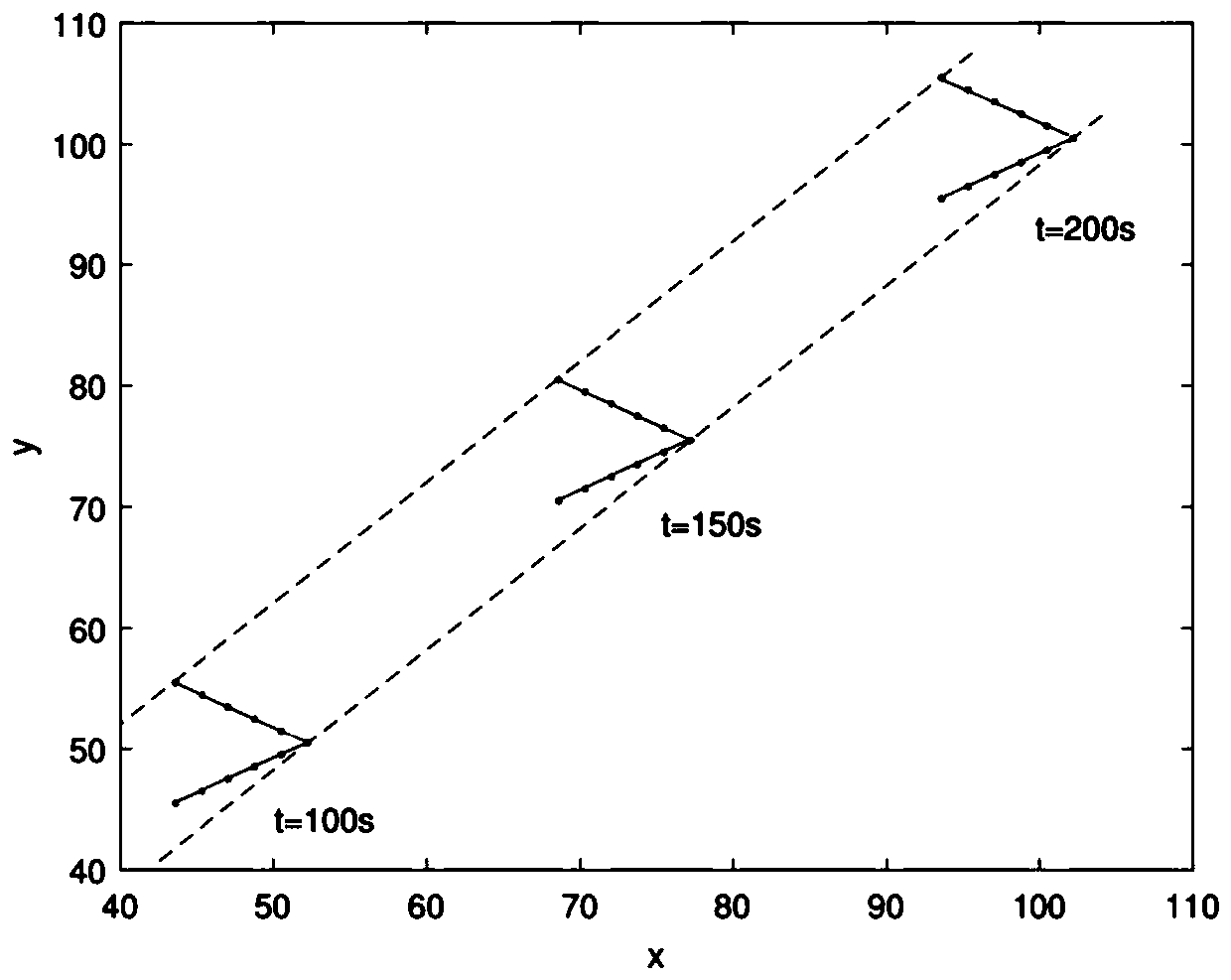

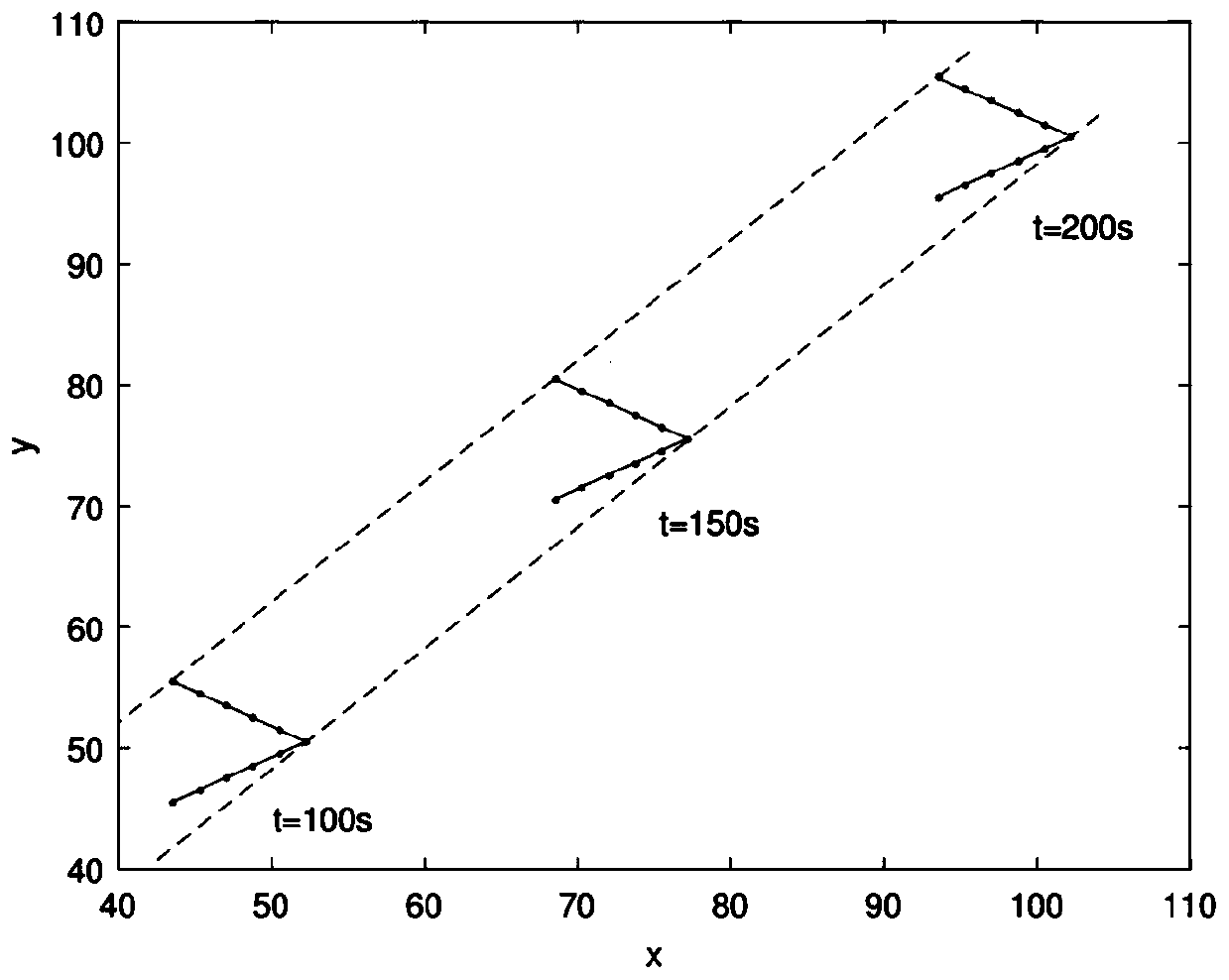

Formation and obstacle avoidance control method for unmanned aerial vehicles in unmanned aerial vehicle system

ActiveCN110865655AImprove task completion rateImprove the ability to deal with emergenciesPosition/course control in three dimensionsUncrewed vehicleObstacle avoidance

The invention discloses a formation and obstacle avoidance control method for unmanned aerial vehicles in an unmanned aerial vehicle system, and belongs to the unmanned aerial vehicle control technology. The method comprises the following steps: S1, carrying out formation of all unmanned aerial vehicles; S2, judging whether an obstacle exists in a set range of the unmanned aerial vehicles or not according to signals collected by the unmanned aerial vehicles at the moment t: if so, switching to step S3, otherwise, switching to step S5; S3, calculating the output of an obstacle avoidance controller of the unmanned aerial vehicles according to the speeds and positions of the unmanned aerial vehicles at the moment t; S4, calculating the speeds and positions of the unmanned aerial vehicles at the moment t+1 according to the output, the speeds and the positions of the unmanned aerial vehicles at the moment t, adjusting the unmanned aerial vehicles at the moment t+1, enabling t to be equal tot+1, and switching to step S2; S5, adjusting the formation, obstacle avoidance and ending methods according to whether the unmanned aerial vehicle system avoids obstacles and whether the unmanned aerial vehicle system reaches the target. The control method provided by the scheme can solve the problems that the unmanned aerial vehicles keep poor obstacle avoidance during formation navigation and cannot be recombined after obstacle avoidance.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

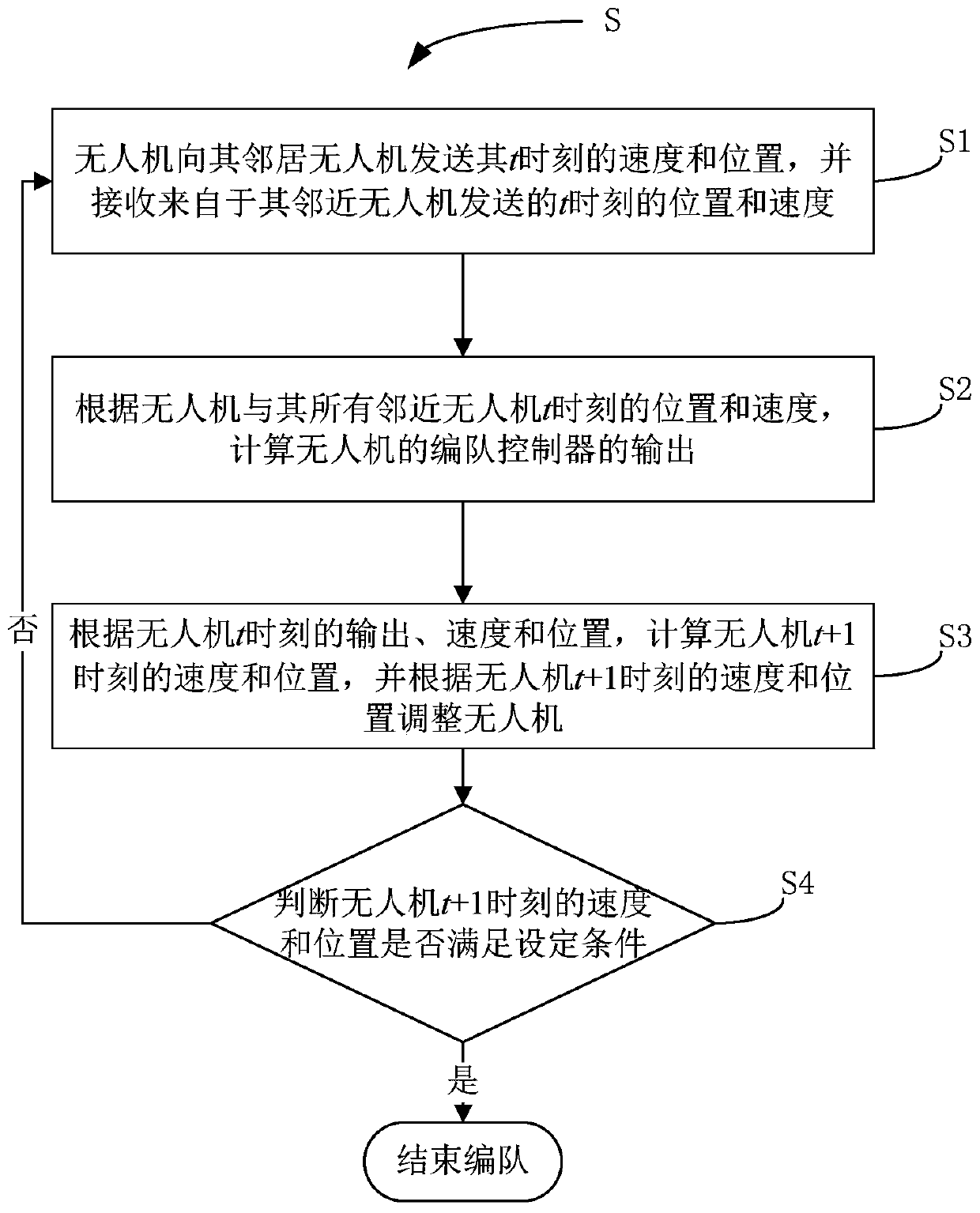

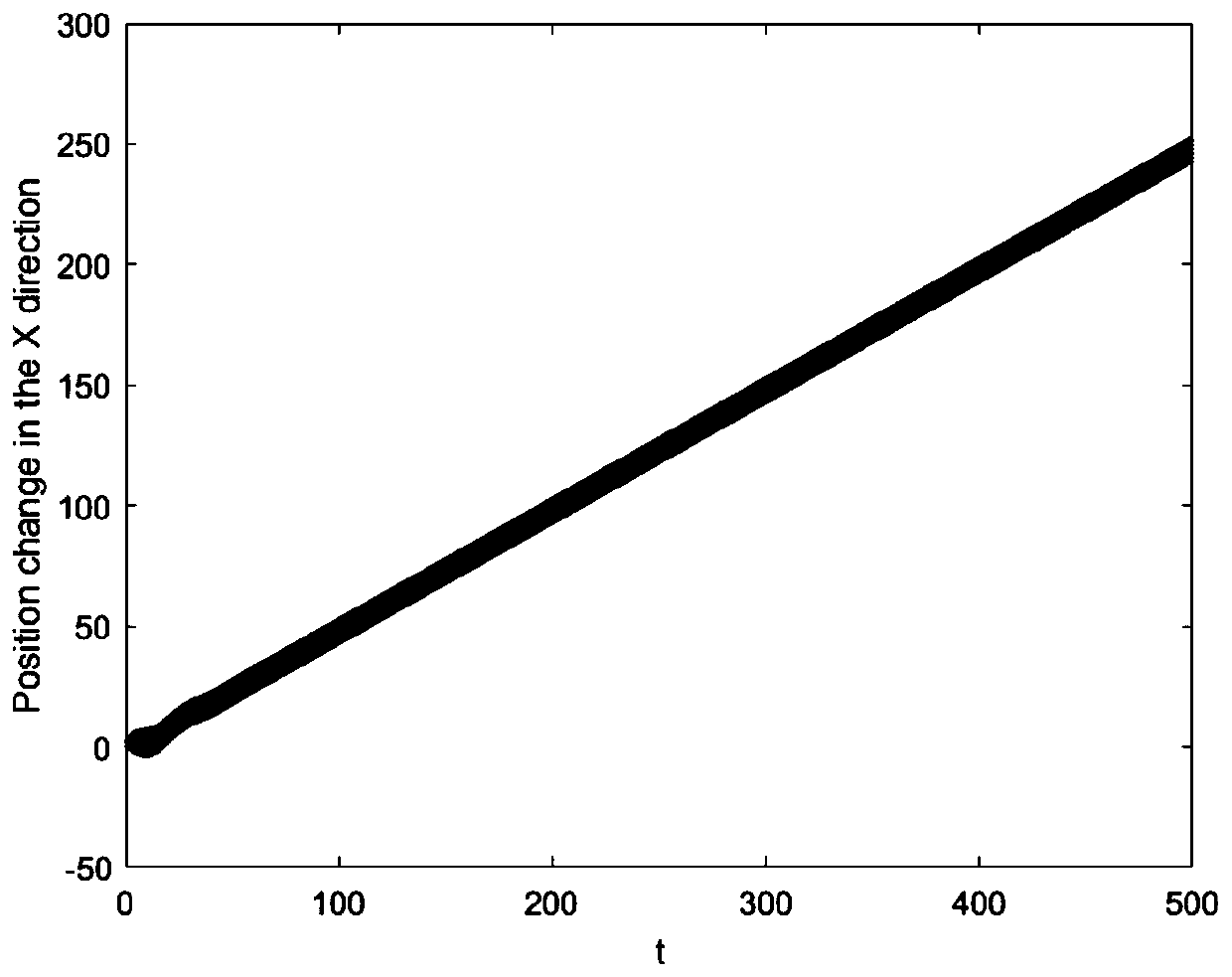

Unmanned aerial vehicle formation method based on time-varying network topology

ActiveCN110825116AGuaranteed Iterative UpdatesNormal outputPosition/course control in three dimensionsTelecommunications linkUncrewed vehicle

The invention discloses an unmanned aerial vehicle formation method based on time-varying network topology, which belongs to the unmanned aerial vehicle control technology, and comprises the followingsteps: S1, enabling an unmanned aerial vehicle to send the speed and the position of the unmanned aerial vehicle at the t moment to neighbor unmanned aerial vehicles, and to receive the positions andthe speeds at the t moment sent by the neighbor unmanned aerial vehicles; S2, calculating the output ui (t) of a formation controller of the unmanned aerial vehicles according to the positions and speeds of the unmanned aerial vehicle and all neighbor unmanned aerial vehicles at the moment t; S3, calculating the speed and the position of the unmanned aerial vehicle at the next moment according tothe output ui (t), the speed and the position of the unmanned aerial vehicle at the moment t, and adjusting the unmanned aerial vehicle; S4, judging whether the speed and the position of the unmannedaerial vehicle at the t + 1 moment meet set conditions or not, if yes, completing formation, otherwise, enabling t to be equal to t + 1, and returning to the step S1. The formation method of the scheme solves the problem that the unmanned aerial vehicles are difficult to form the set formation to sail to the destination under the conditions that the communication environment is poor and a plurality of communication links cannot be well maintained.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

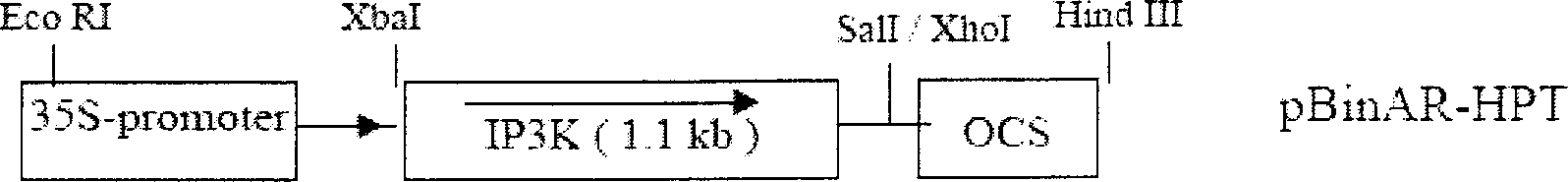

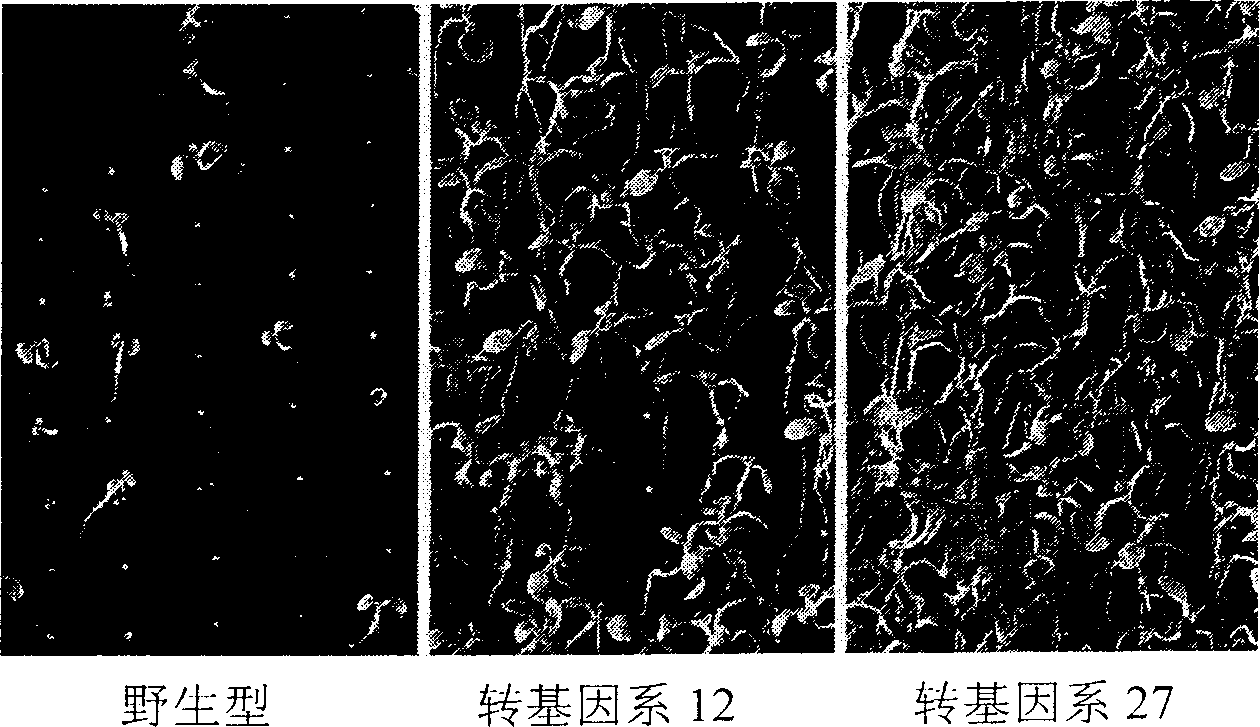

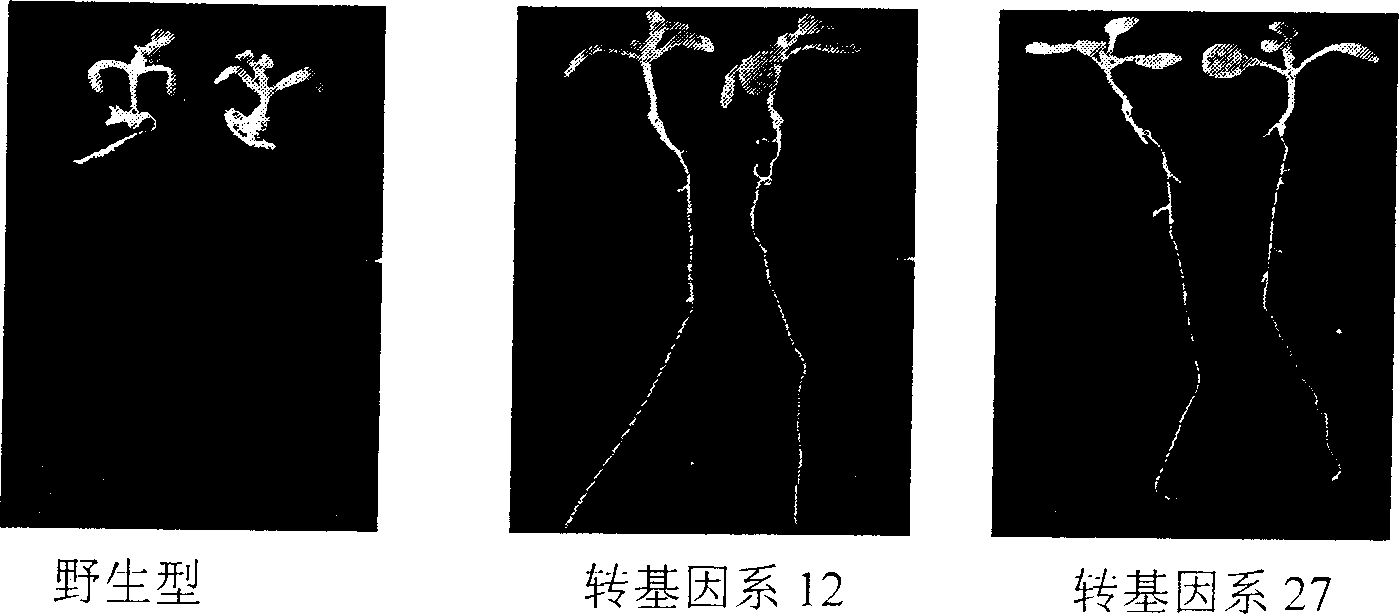

Application of polyphosphoinositide 6-3/kinase gene in plant salt resistance

InactiveCN1847402AImprove salt resistanceImprove salt toleranceHydrolasesFermentationNormal growthSlow growth

The present invention discloses the apply of Arabidopsis thalianum polyphosphoinositide 6- / 3-kinase gene in plant salt resistance. Polyphosphoinositide 6- / 3-kinase gene is first cloned from target plant and then connected to corresponding vector in proper molecular biological and transgenic measures to produce transgenic plant. Applying the gene can provide one technological way for solving the problem that plant, including grain and economic crop, has low survival rate, slow growth speed and low yield in high salt environment, and is favorable to normal growth of plant in high salt area.

Owner:WUHAN UNIV

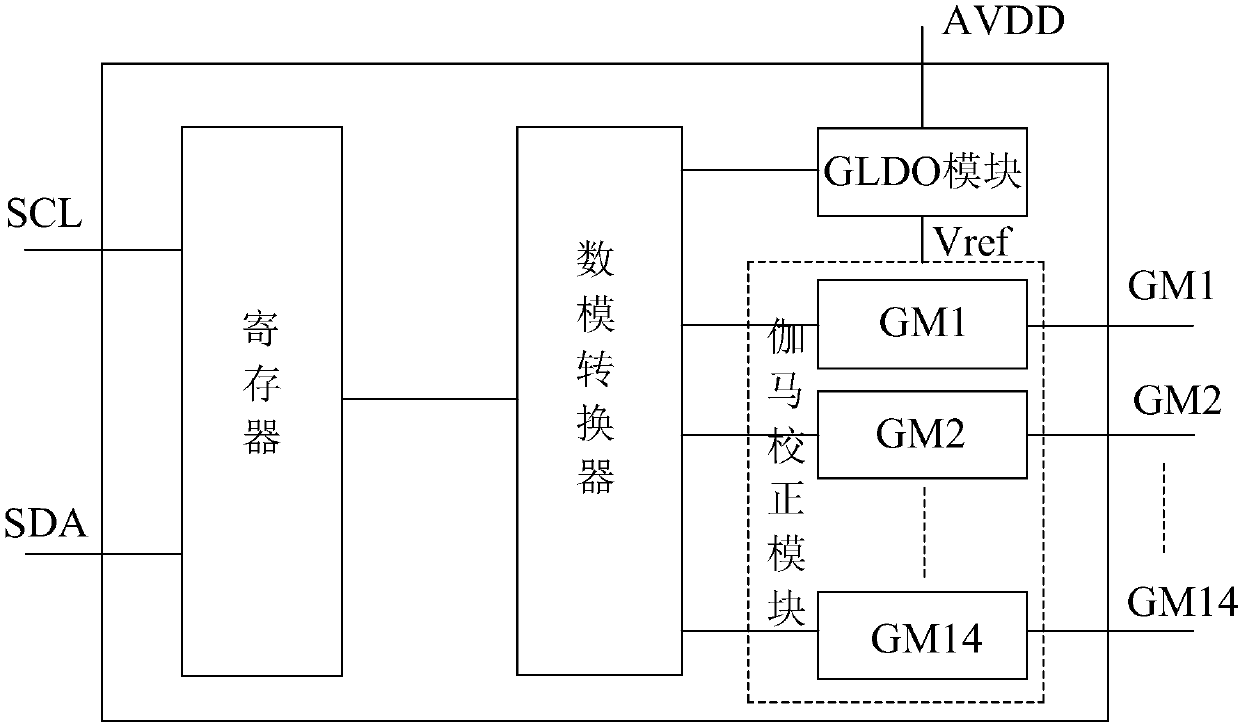

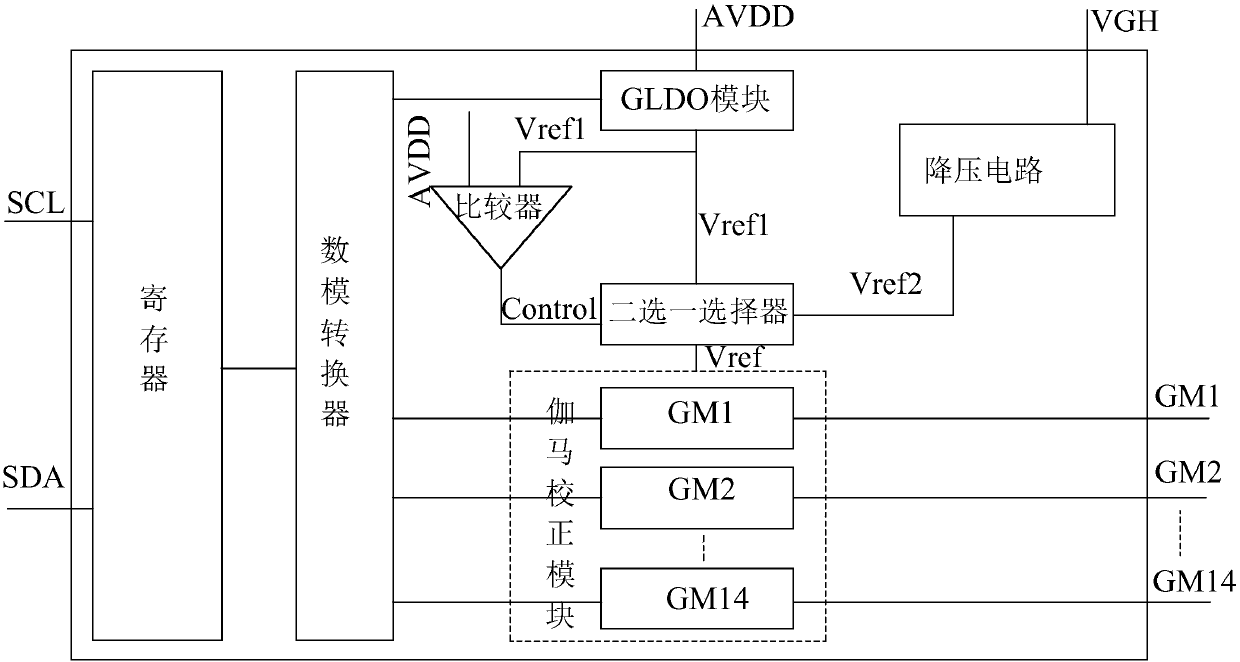

Gamma voltage output circuit based on digital PMIC

The invention relates to a gamma voltage output circuit based on a digital PMIC (Power Management Integrated Circuit). An analog voltage (AVDD) is input to a GLDO module and a comparator, and the GLDOmodule outputs a first gamma reference voltage (Vref1) to the comparator and an either-or selector. A second gamma reference voltage (Vref2) is input to the either-or selector, and the second gamma reference voltage (Vref2) is greater than or equal to a set value of gamma reference voltage (Vref). When the analog voltage (AVDD) is greater than the first gamma reference voltage (Vref1), the comparator makes the either-or selector output the first gamma reference voltage (Vref1) as the gamma reference voltage (Vref). When the analog voltage (AVDD) is smaller than the first gamma reference voltage (Vref1), the second gamma reference voltage (Vref2) is output. The gamma reference voltage (Vref) is output to a gamma correction module, and the gamma correction module outputs a gamma voltage. According to the circuit of the invention, when the analog voltage and the gamma reference voltage are set wrongly in a register, the gamma voltage will not be abnormal, and the display of the picture will not be abnormal.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

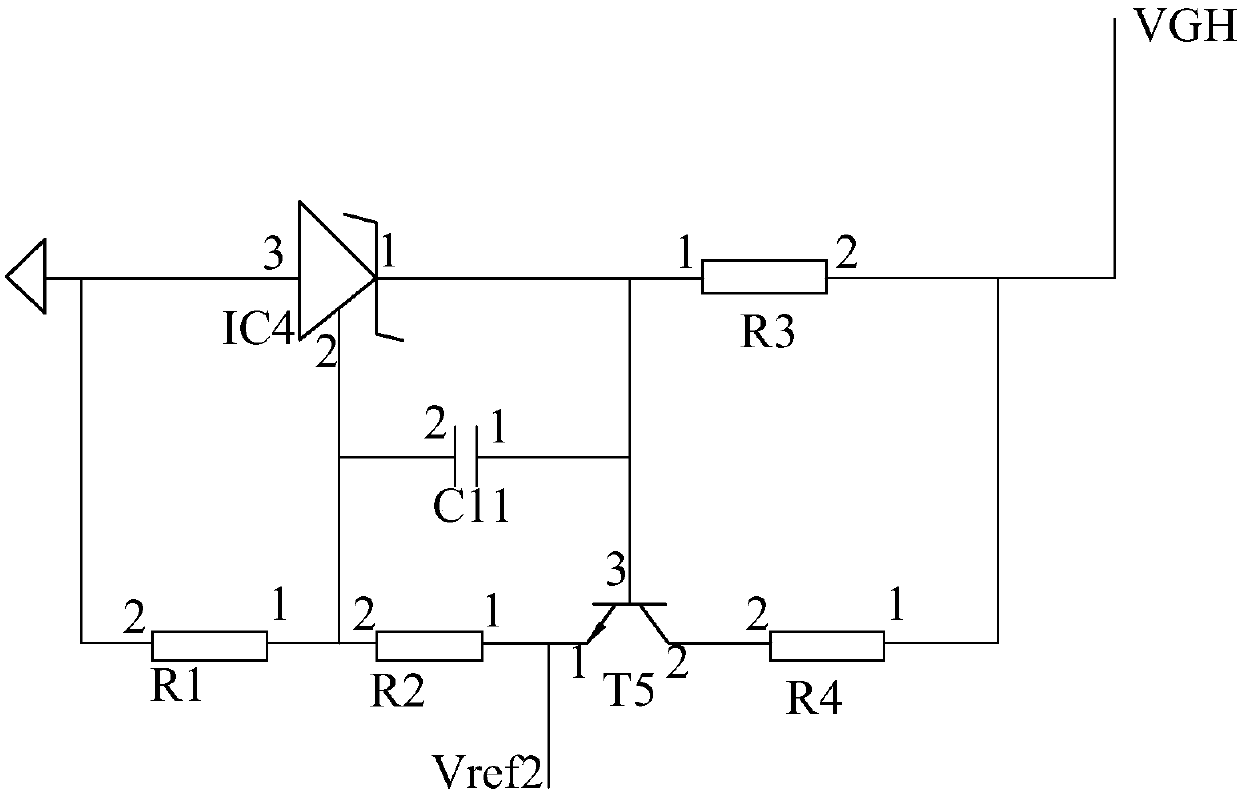

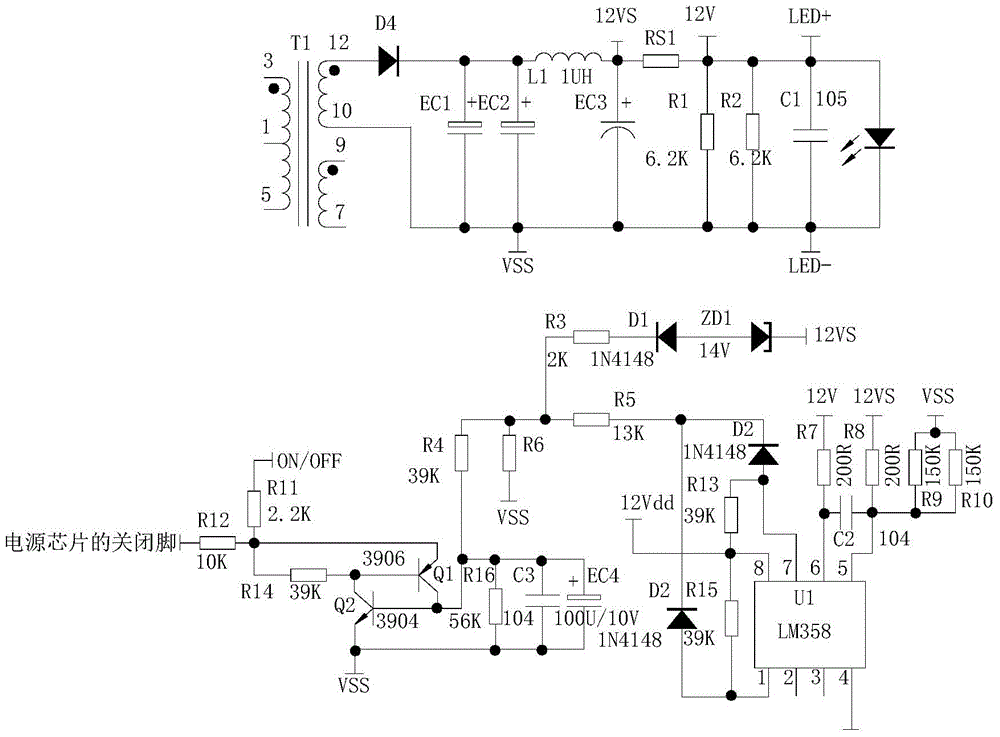

LED constant-voltage power supply with self-locking protecting circuit

InactiveCN104701809AImprove safety performanceFunctionalElectric light circuit arrangementArrangements responsive to excess currentSelf lockingConstant voltage

Owner:珠海绿金能控科技有限公司

Shift register unit, driving method, gate driving circuit and display device

InactiveCN108717844AReduce leakage currentNormal outputStatic indicating devicesDigital storageShift registerDisplay device

The invention provides a shift register unit, a driving method, a gate driving circuit and a display device. The shift register unit comprises a reset circuit, wherein the reset circuit is connected with a pull-up node and is used for resetting the potential of the pull-up node in a reset phase, and the shift register unit also comprises a reset control circuit; the reset control circuit is connected with the reset circuit and is used for controlling and reducing the leakage current of the reset circuit at an output stage so as to maintain the potential of the pull-up node as a first voltage.The shift register unit circumvents the influence of the leakage current of a reset transistor on the output of a gate driving signal, therefore the display is not influenced.

Owner:BOE TECH GRP CO LTD +1

GOA circuit and display device

InactiveCN106803414ANormal outputImprove yieldStatic indicating devicesNon-linear opticsDisplay deviceYield rate

The invention discloses a GOA circuit and a display device. The GOA circuit comprises multiple cascaded GOA units and at least one repair GOA unit. The repair GOA unit is connected with a signal output line of an upper-level GOA unit of one abnormal GOA unit among the multiple cascaded GOA units, a signal output line of a lower-level GOA unit of the abnormal GOA unit and a signal output line of the abnormal GOA unit through a first repair wire, a second repair wire and a third repair wire. Besides the original cascaded GOA units, the repair GOA unit is additionally adopted to replace the abnormal GOA unit, so that the whole GOA circuit can output normally and a yield rate of products is improved. The invention also discloses the display device applying the GOA circuit.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

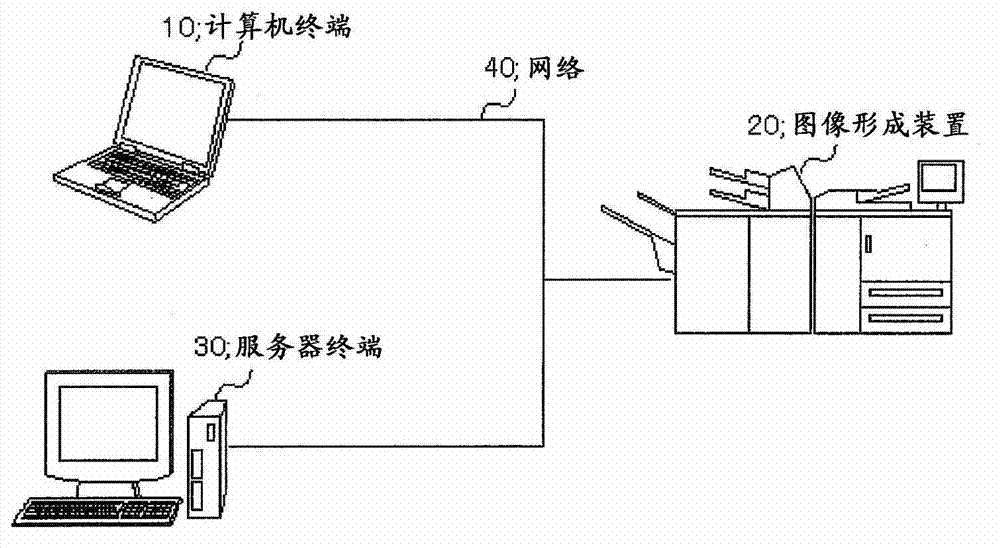

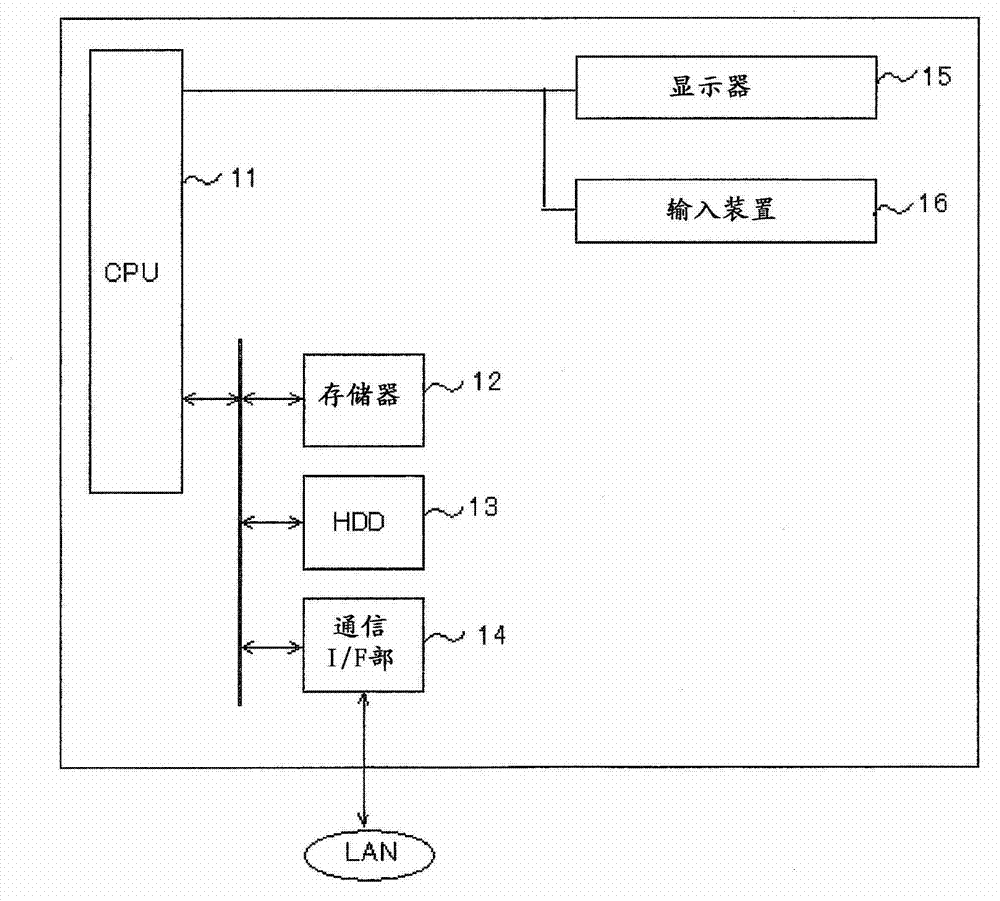

Variable printing system, image forming apparatus, and non-transitory computer readable medium

ActiveCN103164175ANormal outputEfficient outputDigital output to print unitsImage formationProcess engineering

A variable printing system includes: an image forming apparatus including an engine for variable printing; a device communicatively connected to the image forming apparatus; a first control section included in one of the image forming apparatus and the device; and a second control section included in one of the image forming apparatus and the device. The first control section acquires setting information of the engine corresponding to a job instructing variable printing, and performs one of adding the setting information into the job, and storing the setting information in a form of a database. The second control section analyses an output result of a job which has been executed and setting information of the engine corresponding to the job, and instructs the engine, based on a result of the analysis, to change a setting of the engine corresponding to a job to be executed or being executed.

Owner:KONICA MINOLTA BUSINESS TECH INC

Method for rapidly cultivating high-oil high-oleic-acid salt-tolerant peanuts

InactiveCN113455381AShorten the breeding periodImprove qualityPlant genotype modificationBiotechnologyOleic Acid Triglyceride

The invention provides a method for rapidly cultivating high-oil high-oleic-acid salt-tolerant peanuts, and belongs to the technical field of new peanut variety cultivation. High-oil peanuts are used as female parents, high-yield high-oleic-acid peanuts are used as male parents, and hybridization is carried out; hybrid gene detection is performed on F1-generation seeds obtained after hybridization, true hybrids are screened, and false hybrids are eliminated; the F1-generation seeds screened through gene detection are subjected to generation adding in Hainan in November of the current year and are sowed in a field, and hybrid F2-generation seeds are harvested according to a single plant after the seeds are mature in March of the next year; the oil content and the oleic acid content of the F2-generation seeds are detected in a non-destructive mode through a near-infrared instrument, and high-oil high-oleic-acid seeds with the oil content being 55% or above and the oleic acid content being 75% or above are screened; yield identification is carried out on a selected salt-tolerant high-oleic-acid strain, and yield comparison test and salt tolerance identification are carried out on the selected strain. According to the method for rapidly cultivating the high-oil high-oleic-acid salt-tolerant peanuts, a high-oil high-oleic-acid salt-tolerant peanut variety can be rapidly obtained, and the breeding period is shortened by 3 years compared with a common breeding method.

Owner:山东青农产业发展有限公司

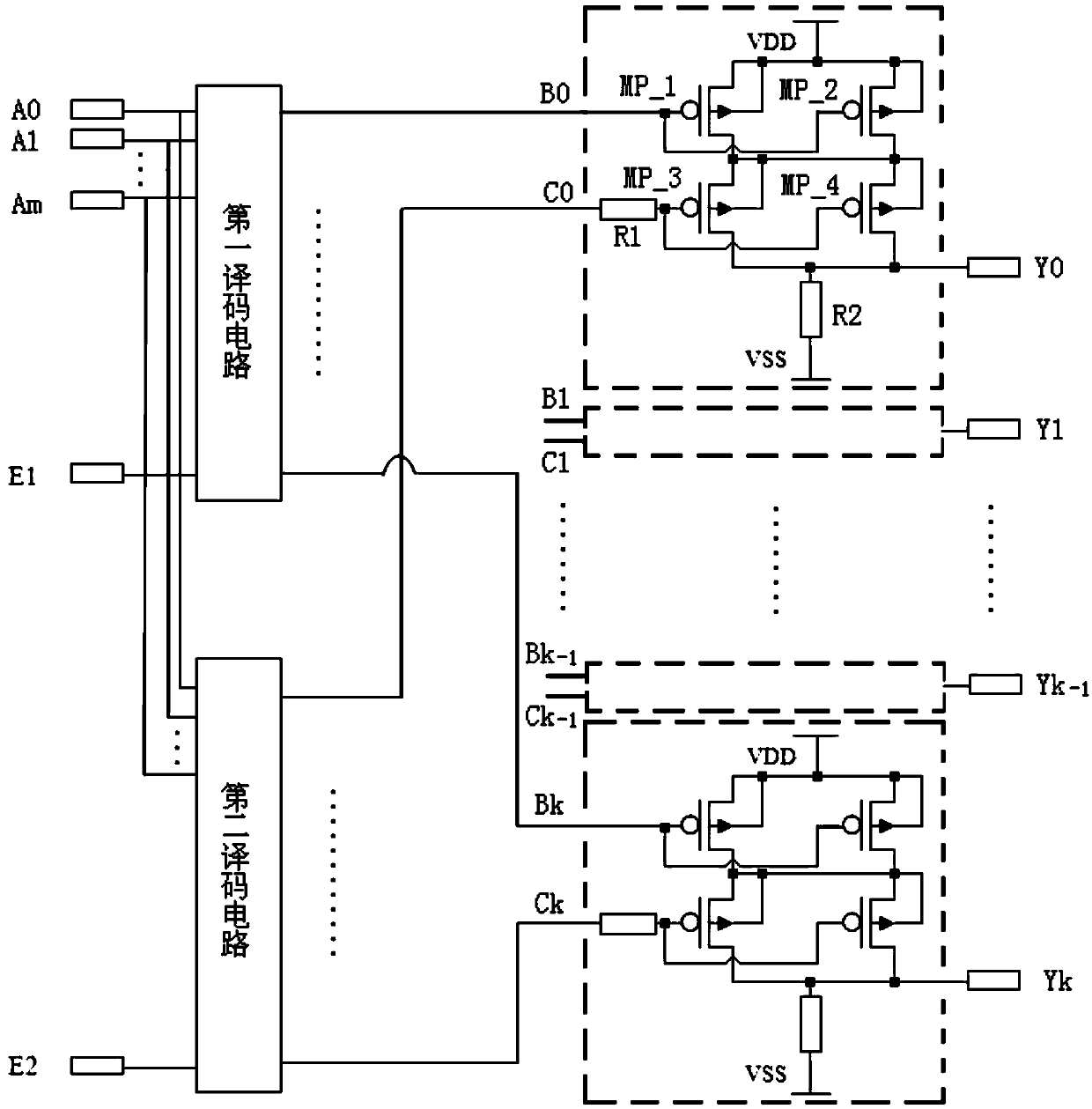

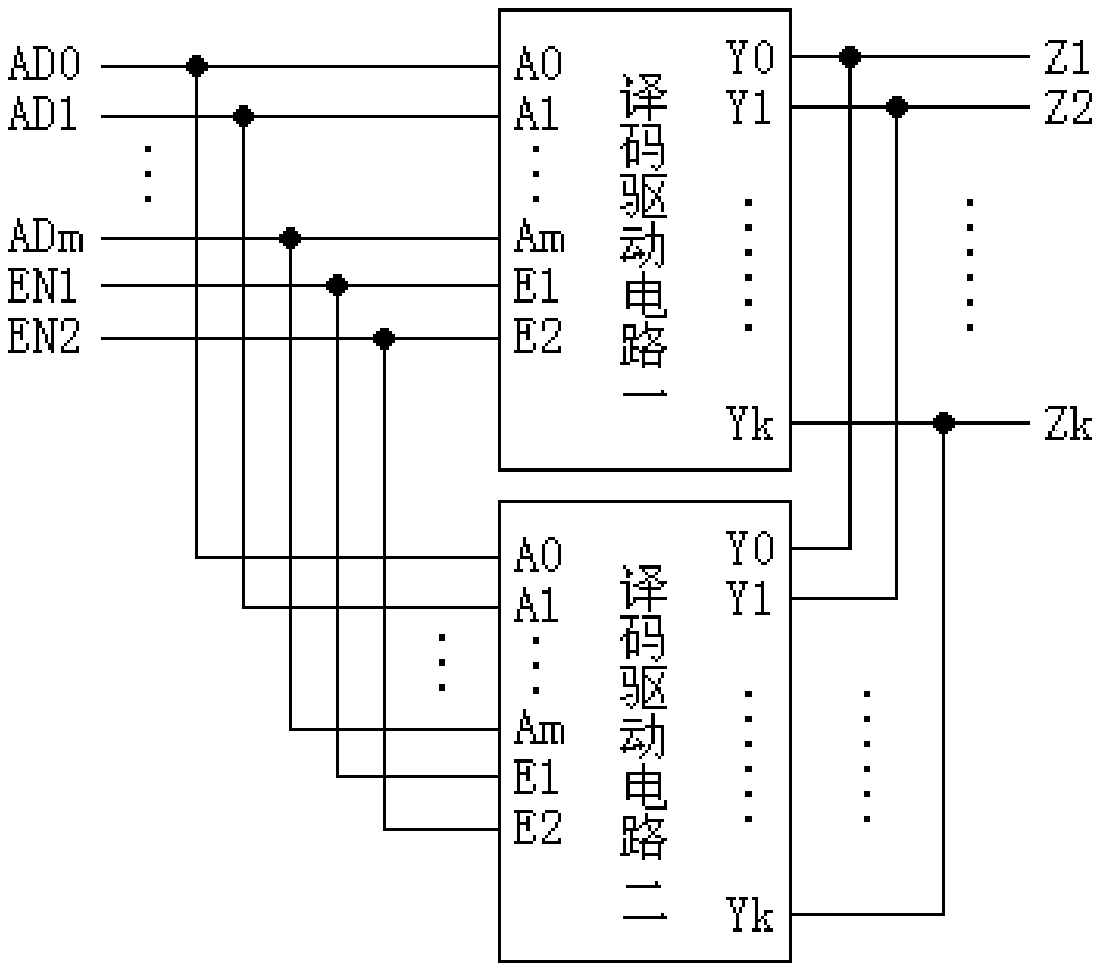

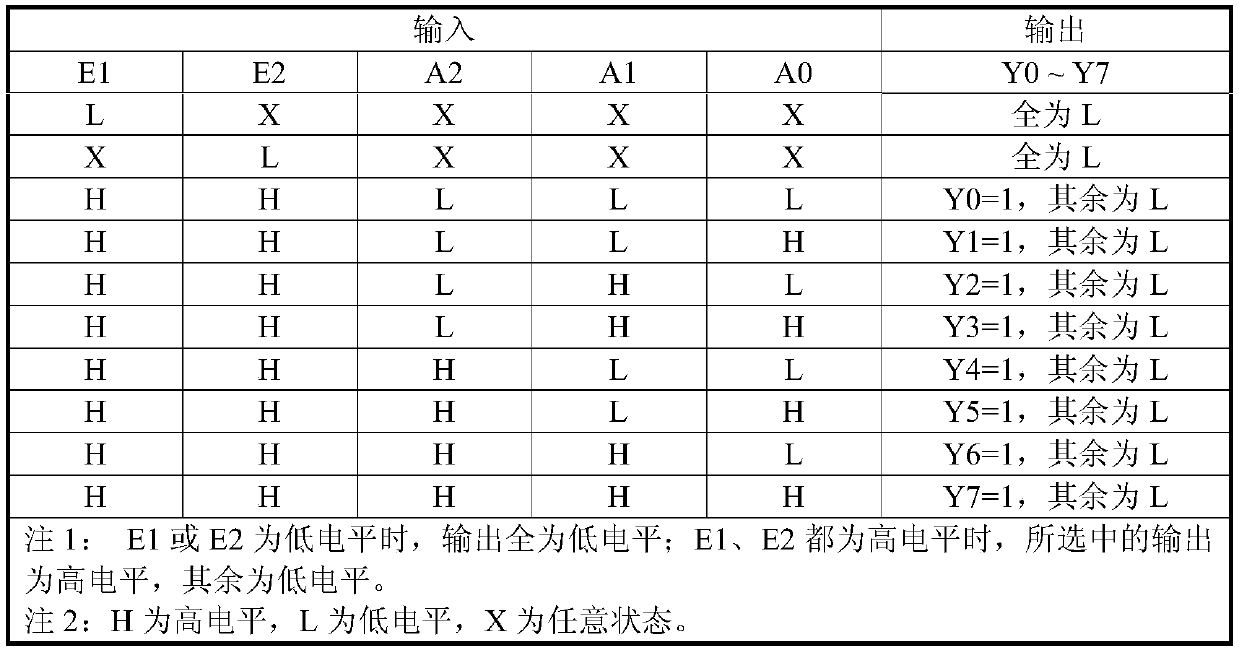

Dual redundant decoding drive circuit for satellites to prevent single point failure, and medium

InactiveCN108683421ANormal outputGuaranteed reliabilityError correction/detection using multiple parity bitsCode conversionControl signalComputer science

The invention relates to a dual redundant decoding drive circuit for satellites to prevent single point failure, and a medium. The circuit includes a dual redundant decoding circuit and a dual redundant output drive circuit. The dual redundant decoding circuit consists of two decoding circuits which have the same structures and are independent with each other; the decoding circuits share a set ofinput signals, separately perform decoding to output two sets of independent decoding signals so that the dual redundant decoding function can be accomplished, and the decoding signals can be used ascontrol signals of a post stage dual redundant output drive circuit; the dual redundant output drive circuit adopts four PMOS output driving tube structures that two of the structures are in parallelconnection and the other two are in series connection; the dual redundant output drive circuit can be controlled by the two sets of independent front stage decoding signals; the output can be the highlevel only when the output PMOS tubes in series are conducted; and the circuit can output normally when a single PMOS tube is in open-circuit or short-circuit state. The dual redundant decoding and dual redundant decoding output drive structure can effectively avoid single point failure, enhance the reliability of the circuits and ensure the correction of output instructions.

Owner:BEIJING MXTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com