Production method of ammonium sulfate

A production method and technology of ammonium sulfate, applied in chemical instruments and methods, ammonia compounds, inorganic chemistry, etc., to achieve the effects of increasing production, reducing production costs, and solving excess production of ammonia water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

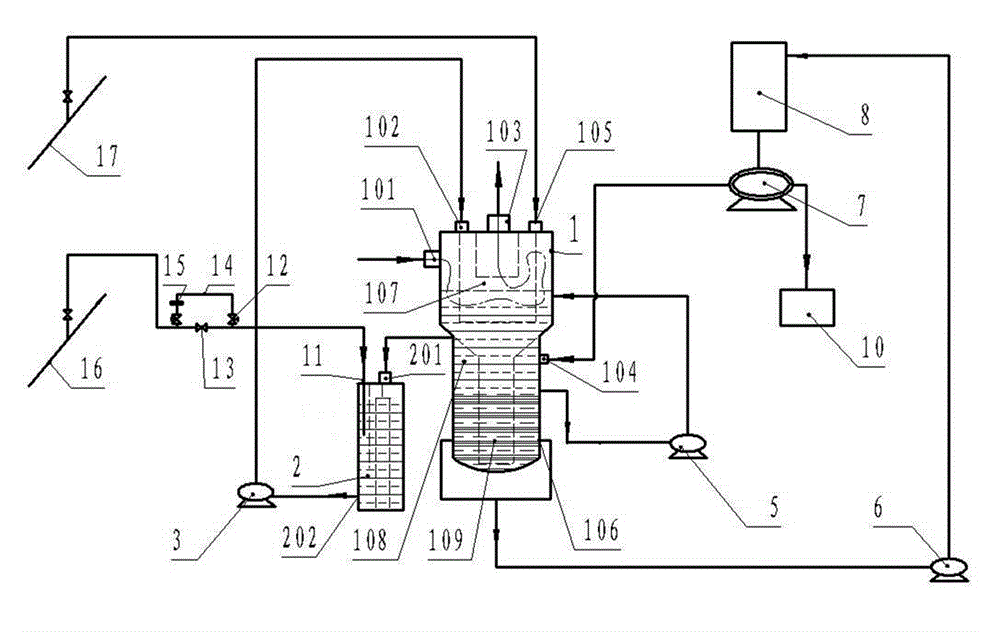

[0019] A kind of production method of ammonium sulfate, use such as figure 1 A kind of ammonium sulfate production equipment shown, this ammonium sulfate production equipment comprises ammonium sulfate production equipment and comprises the saturator 1 that is provided with coke oven gas inlet 101 and coke oven gas outlet 103, in saturator 1 successively arranges There are inter-connected mixing zone 107, spray zone 108 and crystallization zone 109; the coke oven gas inlet 101 of saturator 1 is located on the side wall of the mixing zone 107 of saturator 1, and the coke oven gas outlet 103 of saturator 1 is located in the saturator The top of the mixing zone 107 of 1 is provided with two crystallization solution outlets 106 at the bottom of the crystallization zone 109 of the saturator 1, and the crystallization solution outlet 106 is communicated with the inlet of the crystallization elevated tank 8 through the pipeline and the crystallization pump 6; The outlet is communicat...

Embodiment 2

[0027] The production of ammonium sulfate comprises the following steps:

[0028] A. Coke oven gas and ammonia gas evaporated from coking plant wastewater are sent to the mixing zone of the saturator for mixing, and the mixed gas enters the spray zone of the saturator and is sprayed with a sulfuric acid solution with a concentration of 3%. The reaction gives product a;

[0029] B. The concentration of 15% ammonia water input from the ammonia water output main pipe is 3m 3 The flow rate of / h is introduced into the overflow tank through the conduit, and reacts with the sulfuric acid solution with a concentration of 3% in the overflow tank to obtain product b. The concentration that is sprayed is that the sulfuric acid solution reaction of 3% obtains product c;

[0030] C. The product a obtained by the reaction in step A and the product c obtained by the reaction in step B enter the crystallization zone of the saturator, and the water in the crystallization zone evaporates wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com