Light mesh-type surface tension storage tank

A surface tension storage tank and net-type technology, which is applied in the direction of aerospace vehicle propulsion system devices, etc., can solve problems such as not being able to be used as a storage tank design, and achieve the effects of efficient propellant management, weight reduction, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

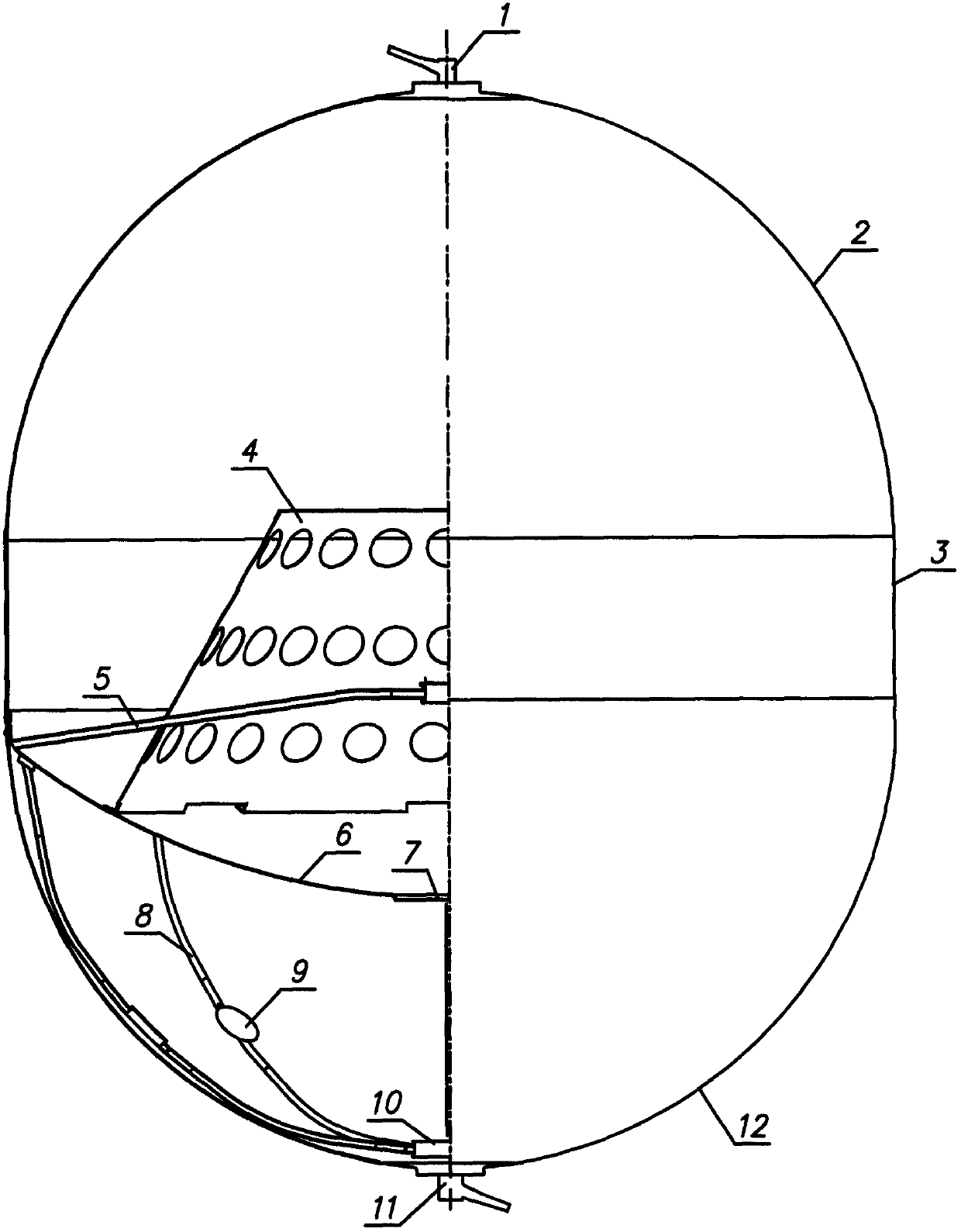

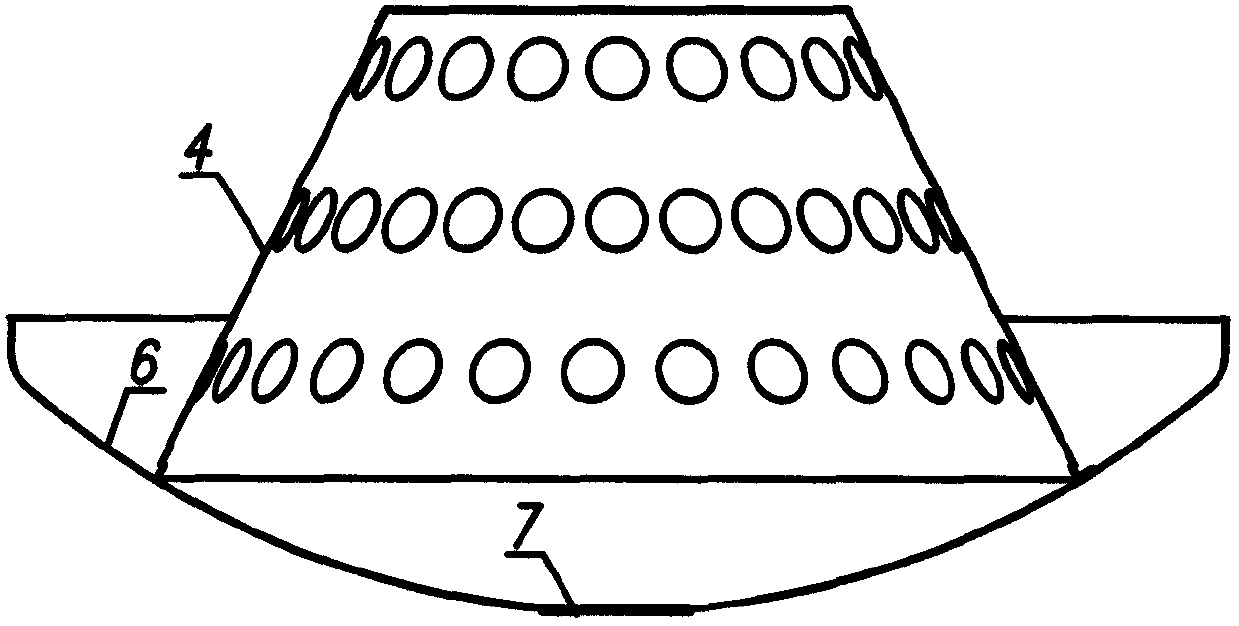

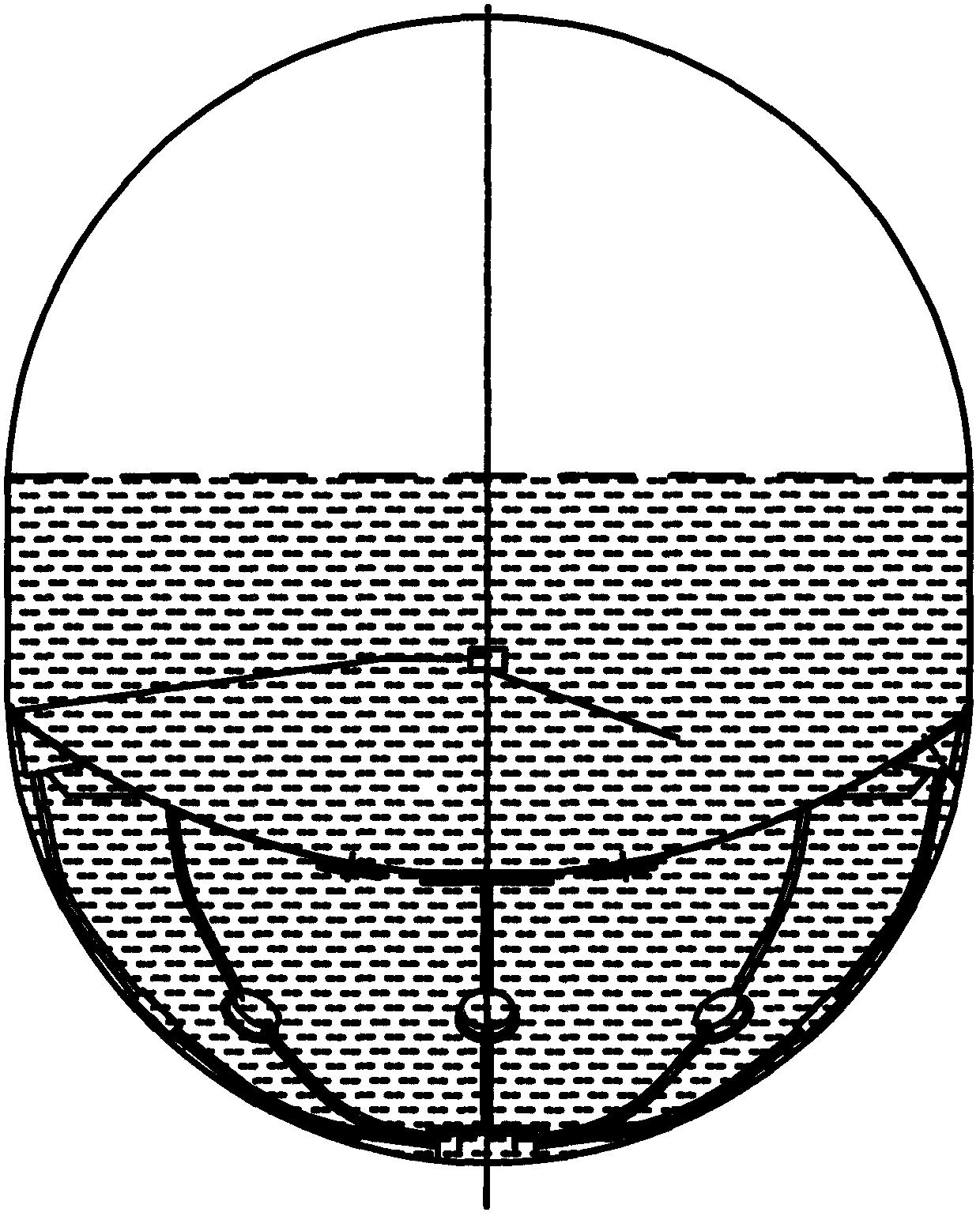

[0025] Such as figure 1 As shown, the present invention consists of an air port 1, an upper hemispherical head 2, a cylindrical section 3, an anti-shake cone 4, an air release cup 5, a middle bottom partition 6, a middle bottom collector 7, a collector connecting pipe 8, and a middle collecting 9, bubble trap 10, liquid port 11 and lower hemispherical head 12, spherical head 6 and cylindrical section 3, air port 1 and upper hemispherical head 6, liquid port 11 and lower hemispherical head 12 respectively Argon arc welding, the smooth transition between the cylindrical section 3 and the upper hemispherical head 6, and the cylindrical section 3 and the lower hemispherical head 12, using the equal strength design principle, the wall thickness of the upper hemispherical head and the lower hemispherical head is 1.05mm, the wall thickness of the cylindrical section is 2.1mm, and its weight is greatly reduced; the middle bottom partition 6 is located at the connection between the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com