Self-inducing magnetic resistance type electromagnetic damper

An electromagnetic damper and reluctance type technology, applied in the direction of shock absorber, magnetic spring, spring/shock absorber, etc., can solve the problems of poor engineering applicability and small damping force, and achieve good anti-swing and anti-swing Effects of impact performance, improvement of output characteristics, and optimized structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

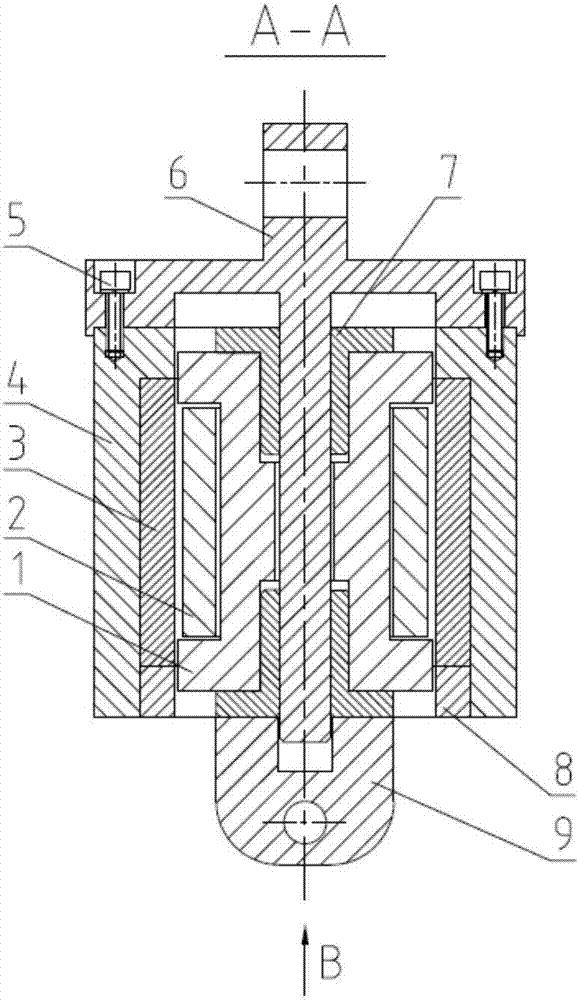

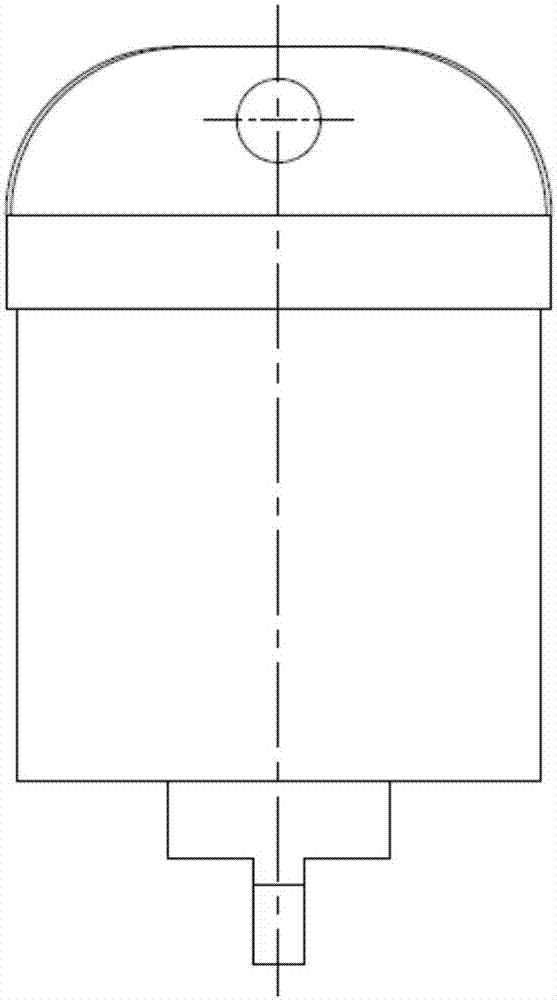

[0020] as attached Figure 1-4 As shown, the present invention provides a self-inductive reluctance type electromagnetic damper, the damper includes a casing stator assembly and an internal mover assembly, the casing stator assembly consists of an annular permanent magnet 3, a permanent magnet upper yoke 4, fastening bolts 5. The upper bracket 6 is composed of the permanent magnet lower yoke 8; the internal mover assembly is composed of a soft magnetic metal yoke 1, a coil 2, a lower bracket 9 and two linear bearings 7;

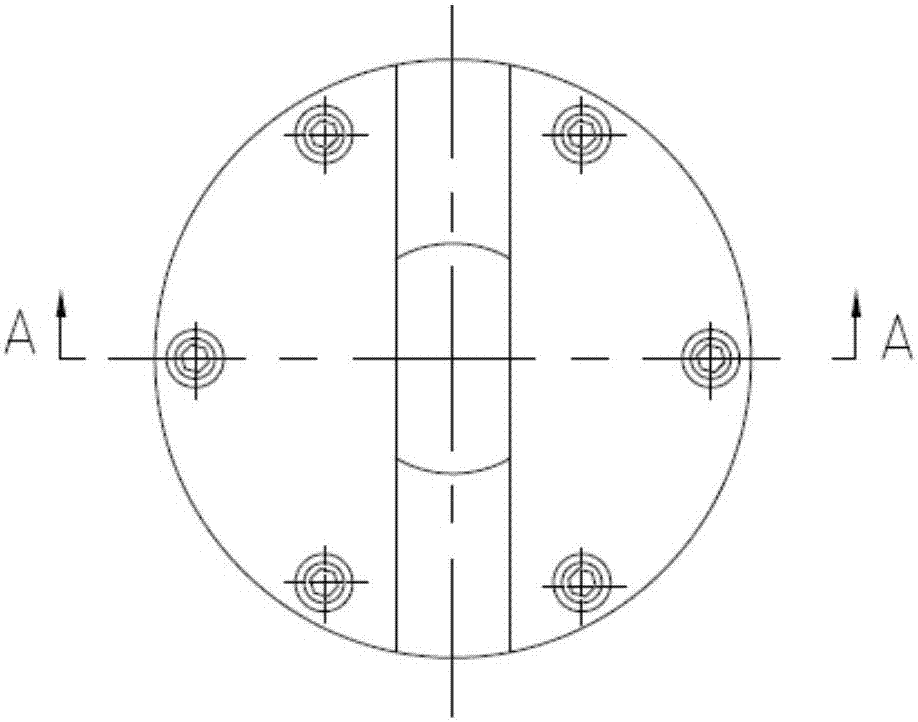

[0021] The upper yoke 4 of the permanent magnet and the lower yoke 8 of the permanent magnet are combined to form an annular cavity for installing the annular permanent magnet 3. The annular permanent magnet 3 is installed in the annular cavity. The upper bracket 6 has a circular end cover, and the end There is a guide shaft in the cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com