Welding-slag splashing prevention device

A technology for anti-welding and welding torches, applied in welding protection devices, welding equipment, welding accessories, etc., can solve the problems of difficult welding slag cleaning, large welding slag spatter, etc., and achieves simple and reliable installation methods, low equipment costs, and positioning methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention are described below, and it should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

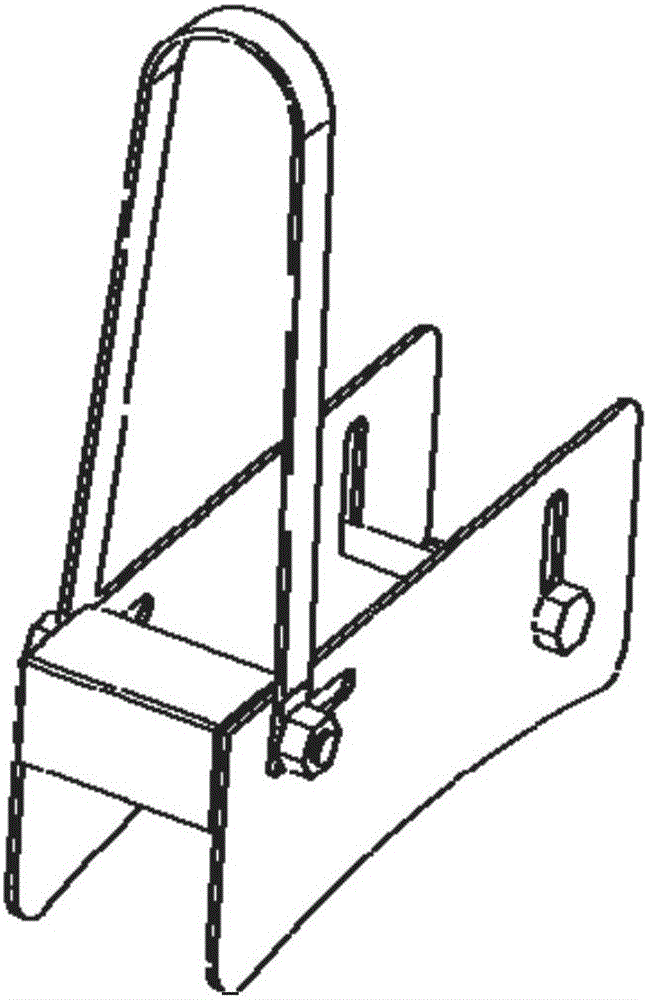

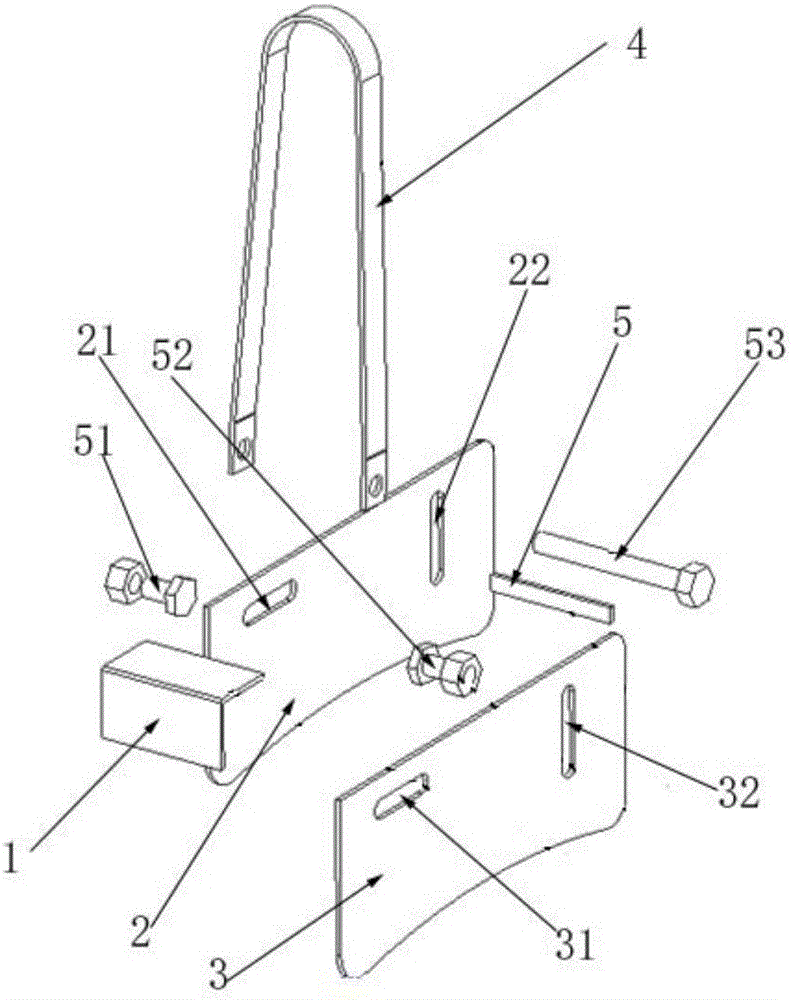

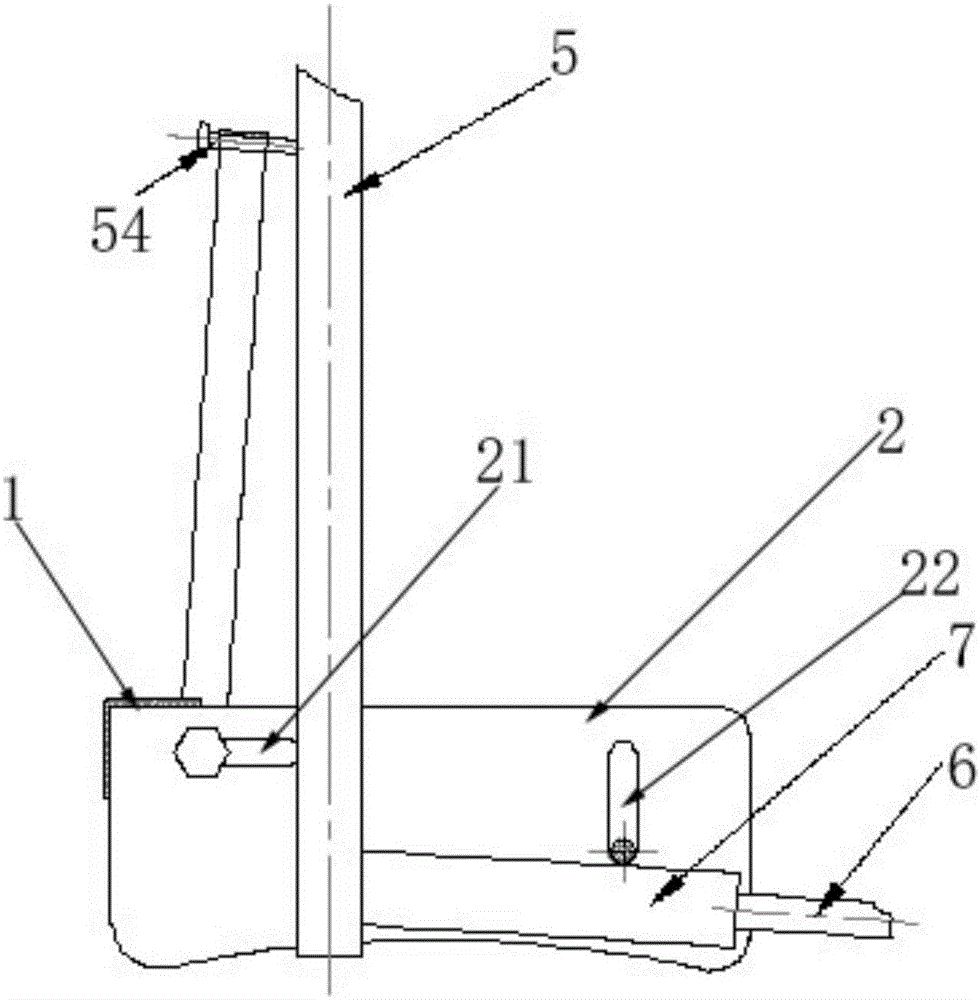

[0029] Such as figure 1 with figure 2 As shown, the welding spatter prevention device provided by the embodiment of the present invention generally includes a front baffle 1 , a first side baffle 2 , a second side baffle 3 , a hook 4 , and a reinforcement bar 5 .

[0030] Specifically, the front fender 1 is located at the front ends of the first side fender 2 and the second side fender 3 and is fixed between the first side fender 2 and the second side fender 3, so that when welding, the front A semi-enclosed space is formed between the baffle plate 1, the first side baffle plate 2, the second side baffle plate 3 and the surface of the welding workpiece to limit the splashing range of welding slag. Preferably, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com