Throttler for air floatation part and air floatation piston comprising throttler

A technology of restrictor and air flotation, applied in air cushion bearings, fluid pressure actuating devices, bearings, etc., can solve the problems of easy blockage and inconsistent throttling flow of the restrictor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

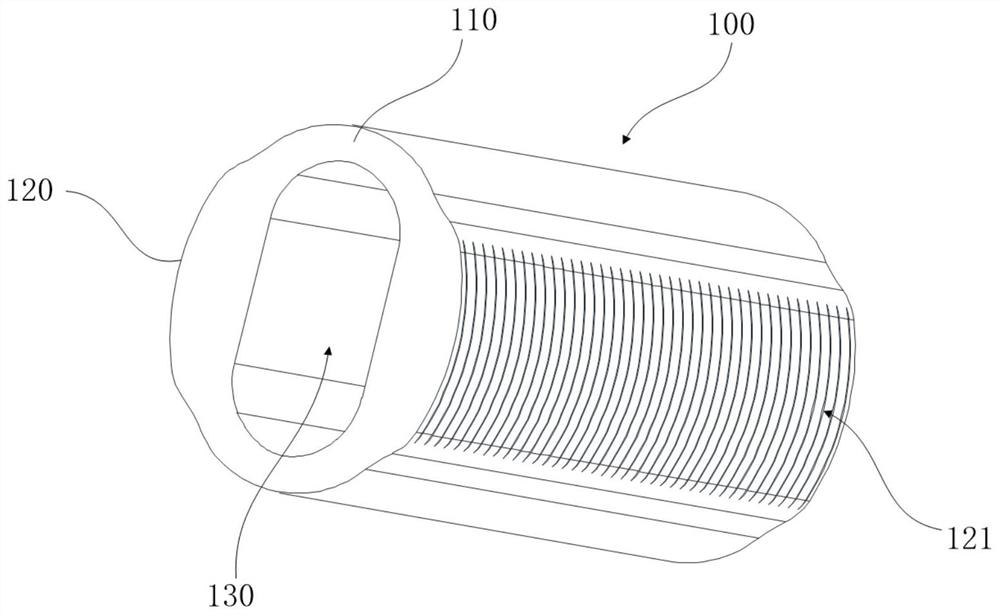

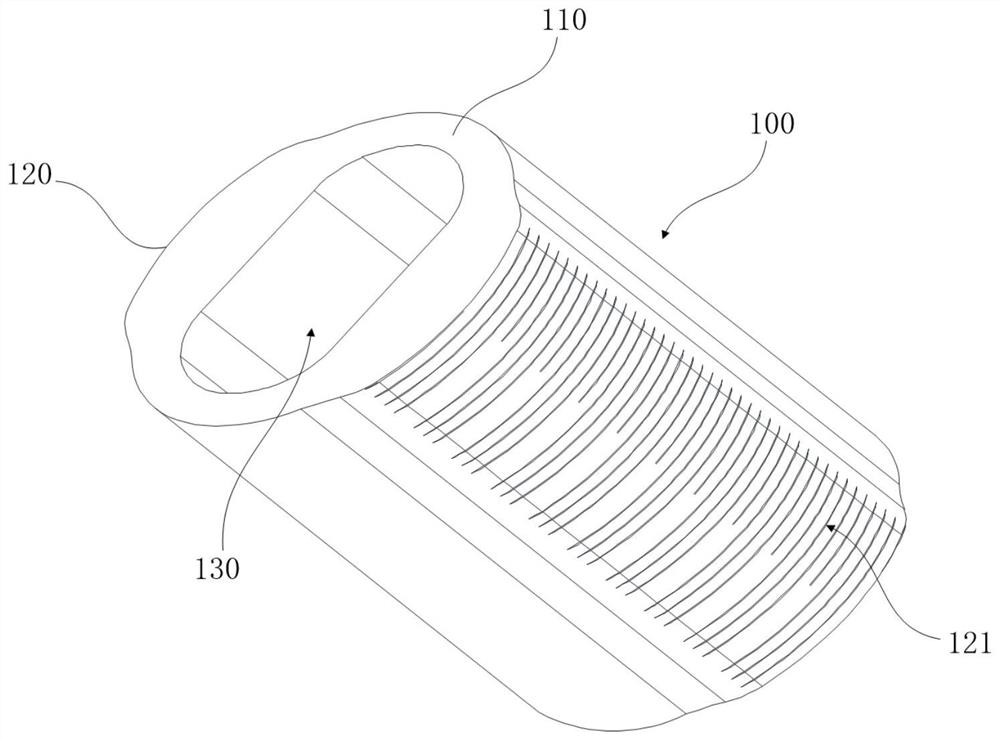

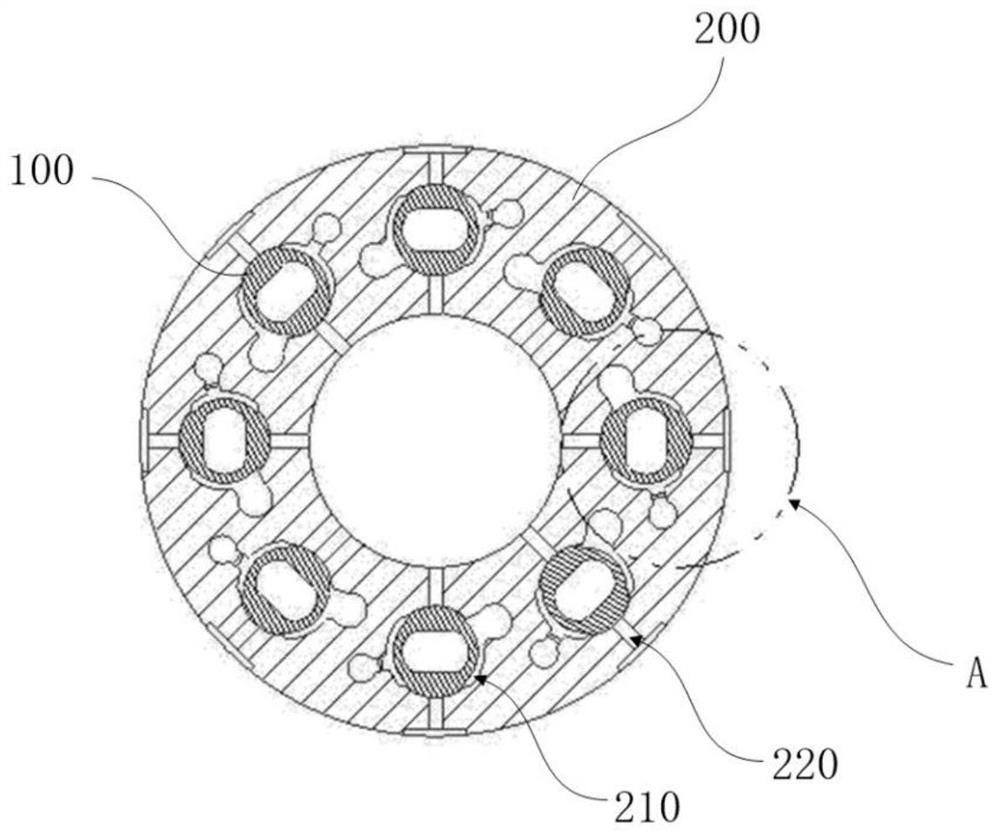

[0048] figure 1 It is a structural schematic diagram of a structure of the restrictor of the present application; figure 2 It is a structural schematic diagram of another structure of the restrictor of the present application; image 3 An assembly drawing of the restrictor and air flotation parts; Figure 4 for image 3 Enlarged image at A.

[0049] Such as Figure 1-4 As shown, the present embodiment provides a restrictor 100 for floating parts, the partial area or the entire area of the outer surface of the restrictor 100 is a rough surface, and the air floating part 200 is provided with a restrictor 100 for installation. The installation cavity 210 and the air outlet hole 220 communicating with the installation cavity 210, the restrictor 100 is fixedly connected to the air outlet hole 220 in the installation cavity 210 through an interference fit connection, and part of the rough surface of the restrictor 100 faces the air outlet hole 220 , after the gas enters the in...

Embodiment 2

[0068] Figure 5 is a schematic diagram of the structure of the air-floating piston; Figure 6 is the side view of the air piston; Figure 7 for Figure 6 Sectional view of B-B direction; Figure 8 for Figure 7 The magnified image at C in the center; Figure 9 It is a schematic diagram of the structure of the piston and the cylinder.

[0069] Such as Figure 5-8 As shown, this embodiment provides an air-floating piston 300, which includes the restrictor 100 as described in the technical solution of Renyi in Embodiment 1, and the air-floating piston 300 in this embodiment is the embodiment The air-floating component 200 described in 1, the air-floating component 200 in this embodiment has the following features in addition to the features of the air-floating component 200 described in Embodiment 1.

[0070] Specifically, the air-floating piston 300 of this specific embodiment includes a piston body 330, the piston body 330 is a circular cylindrical structure, the installa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com