Mounting method for drum washing machine counter weight and mounting structure thereof

The technology of a drum washing machine and installation structure, which is applied to other washing machines, washing devices, textiles and paper making, etc., can solve the problems of increasing workload, affecting the delivery rate of the whole machine, failing to save costs, etc. Reliable installation method, the effect of saving settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

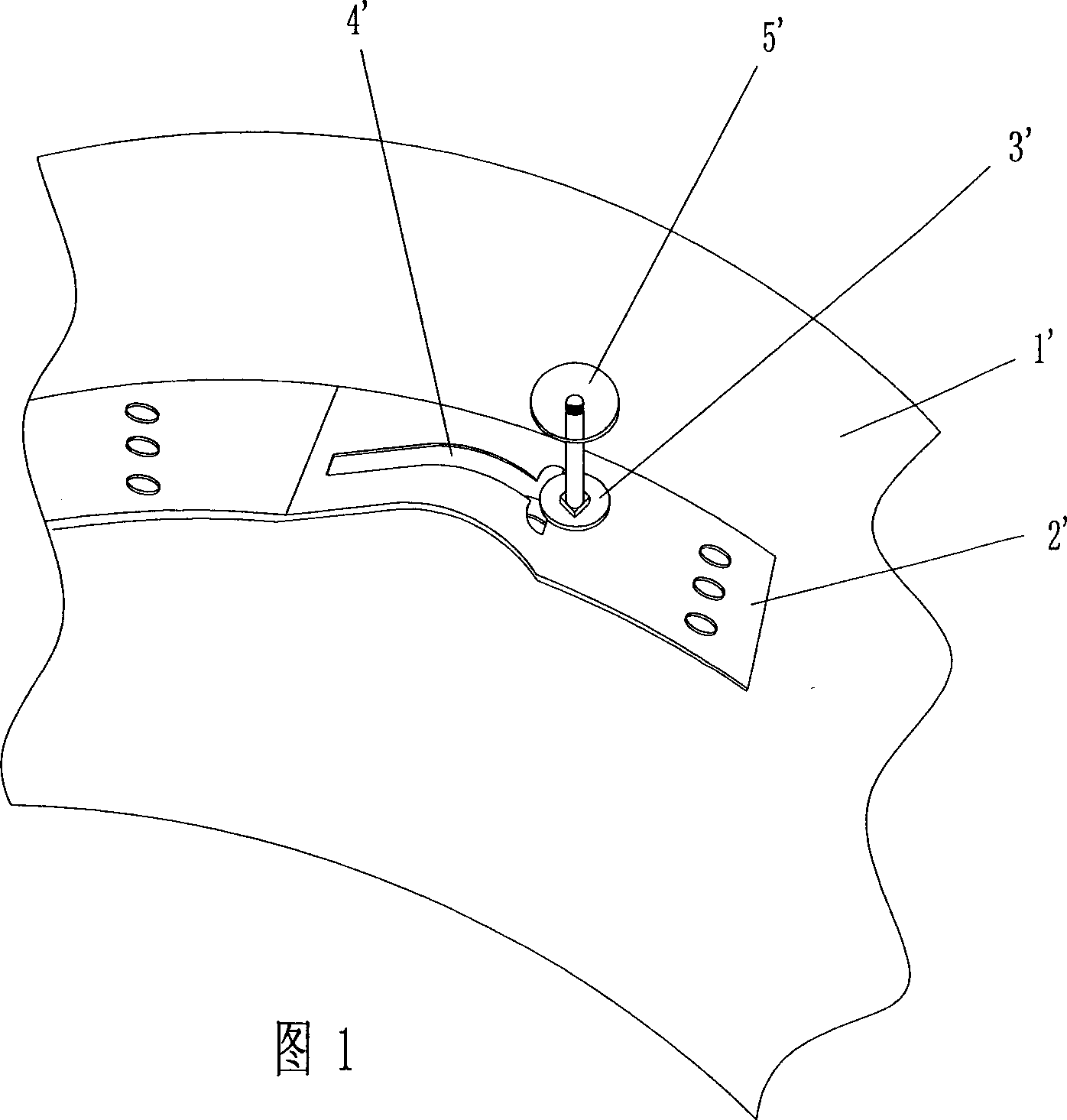

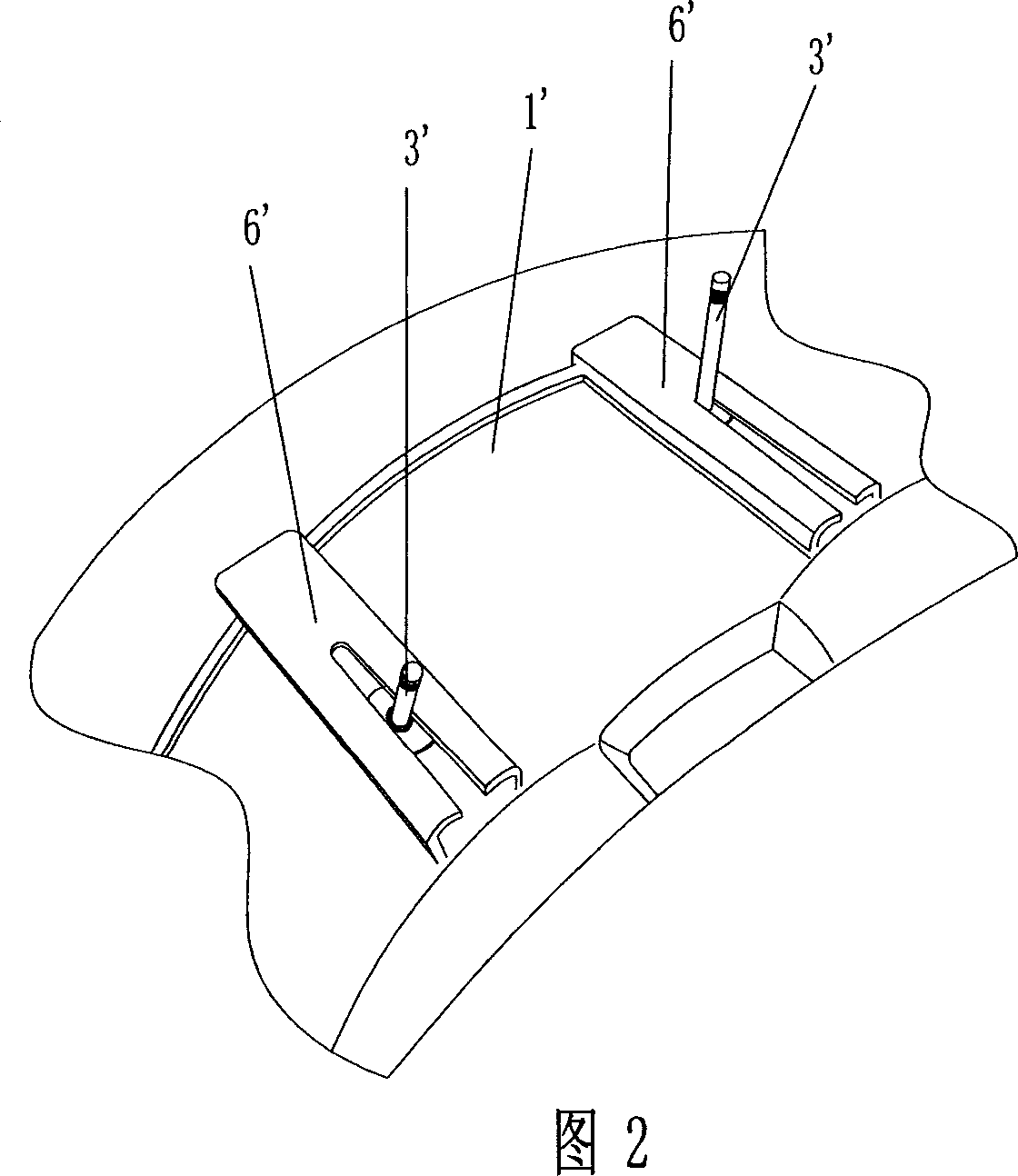

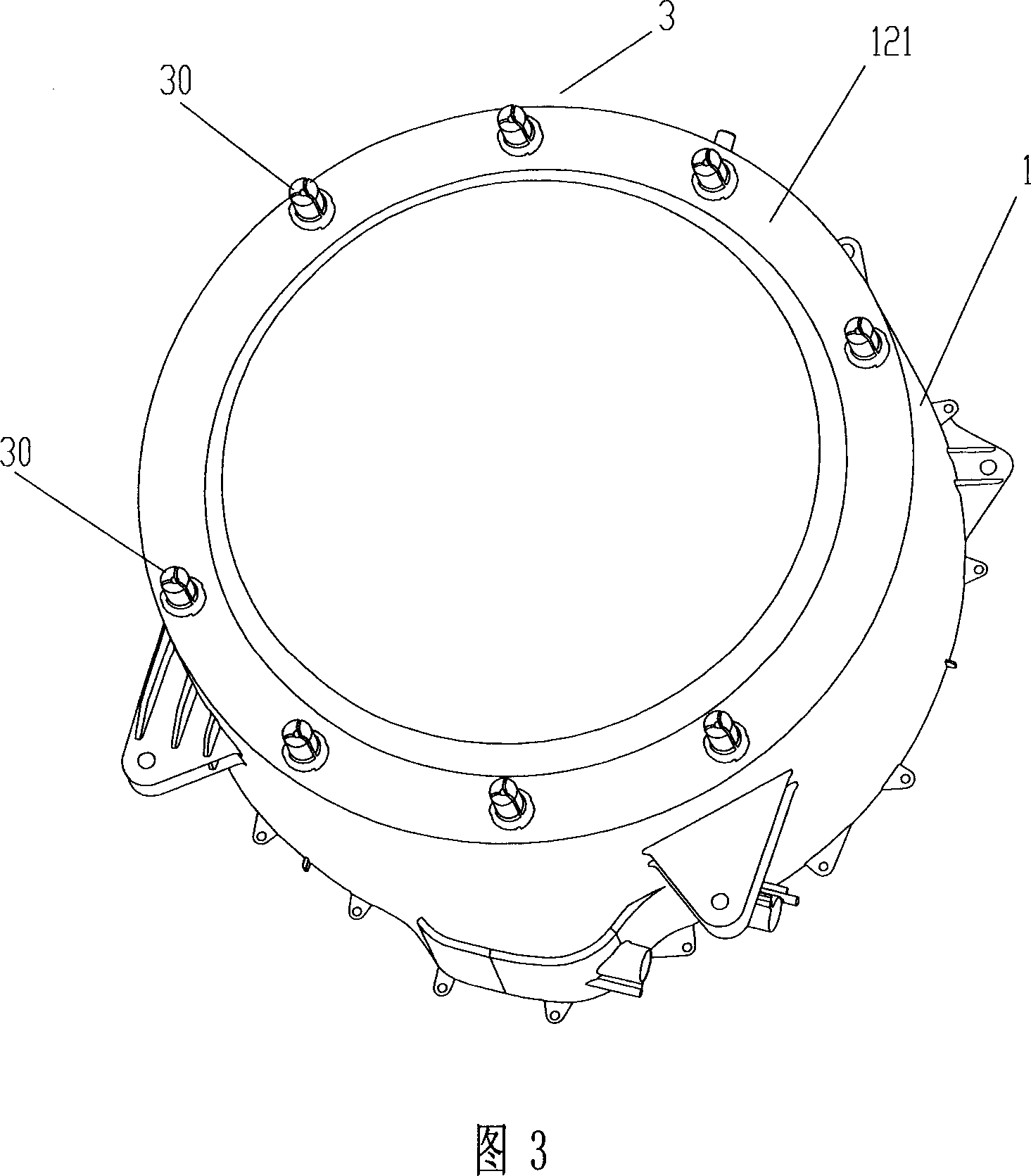

[0041] The fixing device 3 is arranged on the end surface 121 of the front end 12 of the outer cylinder, the fixing device 3 adopts an expansion bolt column, and the fastening device 4 adopts a screw; The installation through hole 21 on the top passes through the fixing device 3, and is installed and fixed on the end surface 121 of the front end 12 of the washing machine outer cylinder 1 through the fastening device 4; the fixing device 3 is at least two expansion bolt columns 30, and the fastening device 4 The fixing device 4 is a screw 40 with a diameter slightly smaller than the diameter of the expansion bolt column. The expansion bolt column 30 is divided into three parts, and the center of the expansion bolt column is provided with a screw installation hole 301 for plugging and fixing the screw 40. When the screw 41 is squeezed into the screw installation In the hole 301, the expansion bolt column 30 is pressed outwards, and the column expands outwards and presses it tight...

Embodiment 2

[0047] The structures of the fixing device and the fastening device are the same as those in Embodiment 1, except that the fixing device 3 is arranged on the top outer surface 11 of the washing machine tub 1 .

[0048] As shown in FIG. 7 , the expansion bolt column 3 is arranged on the top outer surface 11 of the washing machine tub 1 , and the counterweight is removed in order to clearly show the expansion bolt column and the fastening device in the figure.

[0049] Usually, when the expansion bolt column 3 is arranged on the top outer surface 11 of the washing machine tub 1, it is sufficient to arrange between 2 and 4 expansion bolt columns 30, and the counterweight can be an arc-shaped solid block, and its radian is the same as The curvature of the washing machine tub 1 matches; or, the counterweight 2 is a fixed block of any shape. In addition, the expansion bolt column 3 can also be in the form of plastic expansion anchor bolts, metal expansion anchor bolts, strong expans...

Embodiment 3

[0052] The present invention proposes a new connection method: the plug-in method combined with the deformed bolt, that is, on the basis of the existing plug-in method, the fixing device screws in Embodiments 1 and 2 are changed to those in the prior art. Hollow rivet structure, although the hollow rivet is a prior art, no one has applied this technology to the field of washing machines at present. This technical solution is adopted in the present invention, and it is applied to the connection method between the counterweight and the washing machine to obtain The utility model achieves unexpected beneficial effects, overcomes the defects of the prior art, simplifies the installation procedure and improves the installation efficiency, and the fixing firmness between the counterweight and the washing machine is better than that of the prior art.

[0053] As shown in Figure 8, Figure 8a, and Figure 8b, the counterweight 2 is installed on the boss 31 through the installation throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com