Low-noise high-navigational-speed large-depth underwater unpowered upwards-floating test platform

A test platform and low-noise technology, applied in underwater operation equipment, transportation and packaging, ships, etc., can solve the problems of poor low-frequency noise reduction effect in the pool, influence and other problems, and achieve simple and reliable processing and installation methods. The effect of strong adaptability and convenient disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

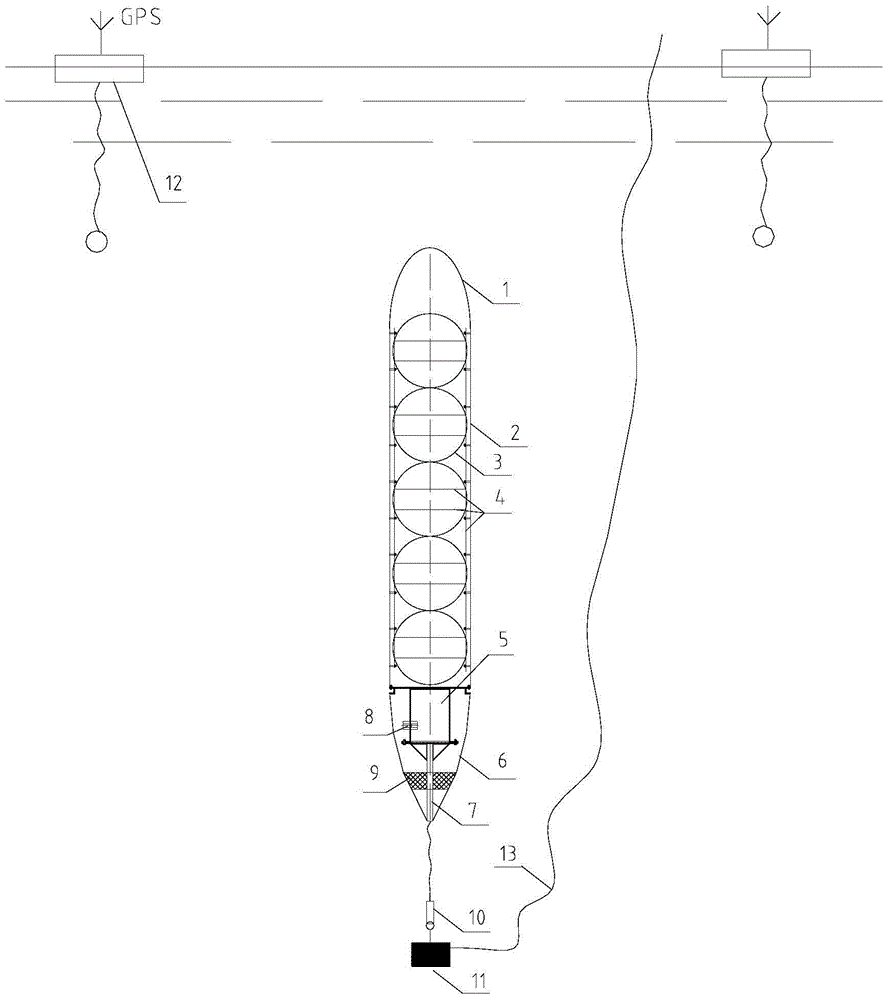

[0031] A low-cost, low-noise, high-speed and deep-water floating test platform figure 1 , including: the bow end 1 of the metal outer shell, the parallel midship of the metal outer shell 2, the steel pressure-resistant hollow floating ball 3, the lightweight floating ball outer frame 4, the electronic cabin 5, and the stern of the metal outer shell 6 , the stern bearing rod 7, the electronic cabin cup-shaped pipe joint 8, the stern configuration block 9, the release device 10, the weight 11, and the protection rope 13. A number of floating balls 3 are combined with a light floating ball outer frame 4 to form a buoyancy device, which provides floating force for the entire test platform. The bow end 1, the parallel midship 2 and the stern 6 of the metal outer shell form an outer shell with low resistance and low noise, and the object to be tested (such as an appendage structure, etc.) can be installed on the outer shell for testing.

[0032] There are water-permeable air holes ...

Embodiment 2

[0053] Implementation example 2, on the basis of embodiment 1, the bow end 1 is refitted with different line-type structures and then tested, so that the comparison of near-field noise and far-field noise under different line types can be realized.

Embodiment 3

[0054] Implementation Example 3, on the basis of Example 1, a stabilizer is installed on the stern to make the platform more stable when floating, and less likely to be disturbed by test objects such as appendages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com