High-speed forming machine for gift boxes

A molding machine, gift box technology, applied in the direction of carton/carton manufacturing machinery, paper/cardboard containers, containers, etc., can solve the problems affecting the forming efficiency of gift boxes, etc., to achieve a compact and reliable overall structure, coherent action, and floor space. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

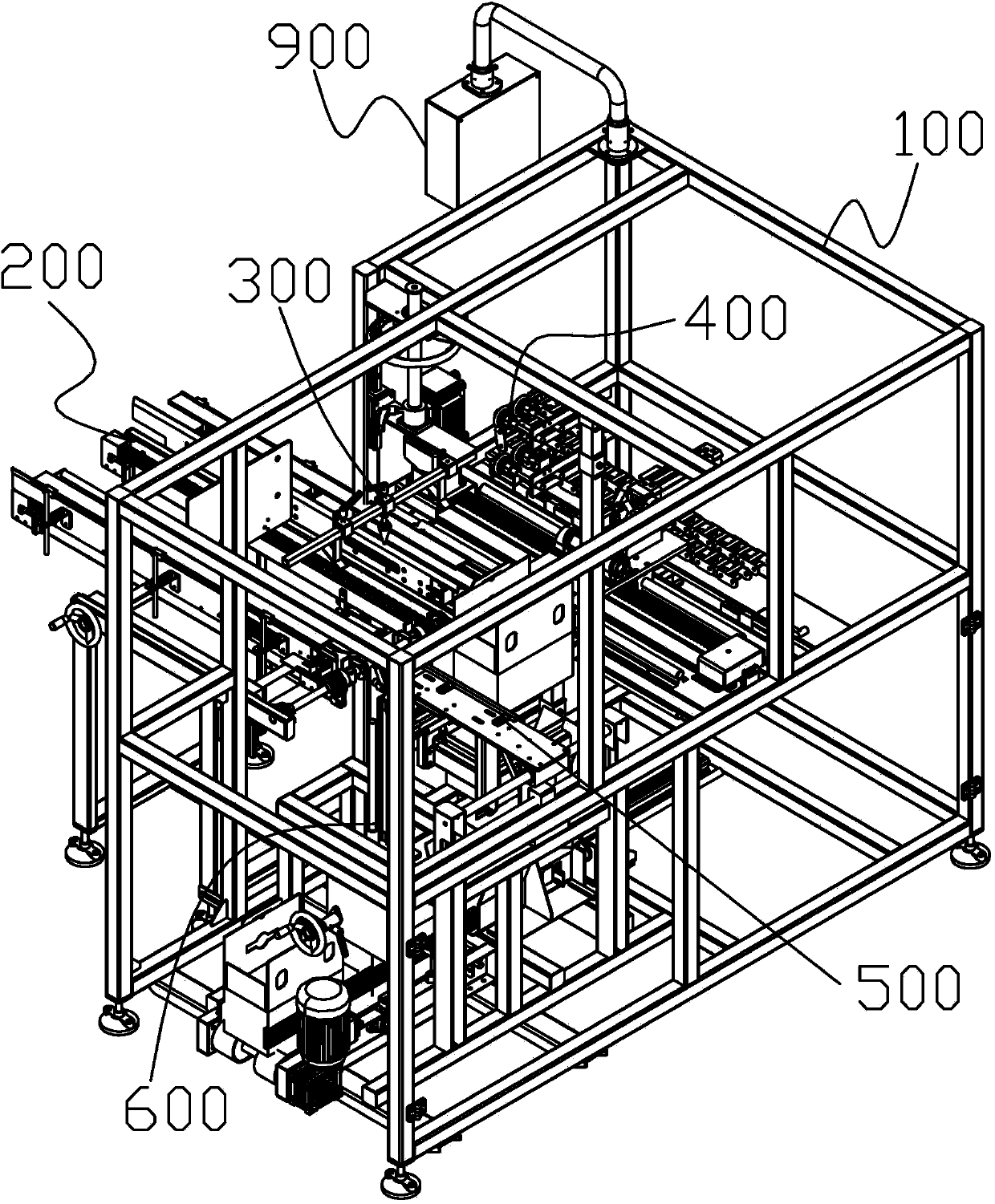

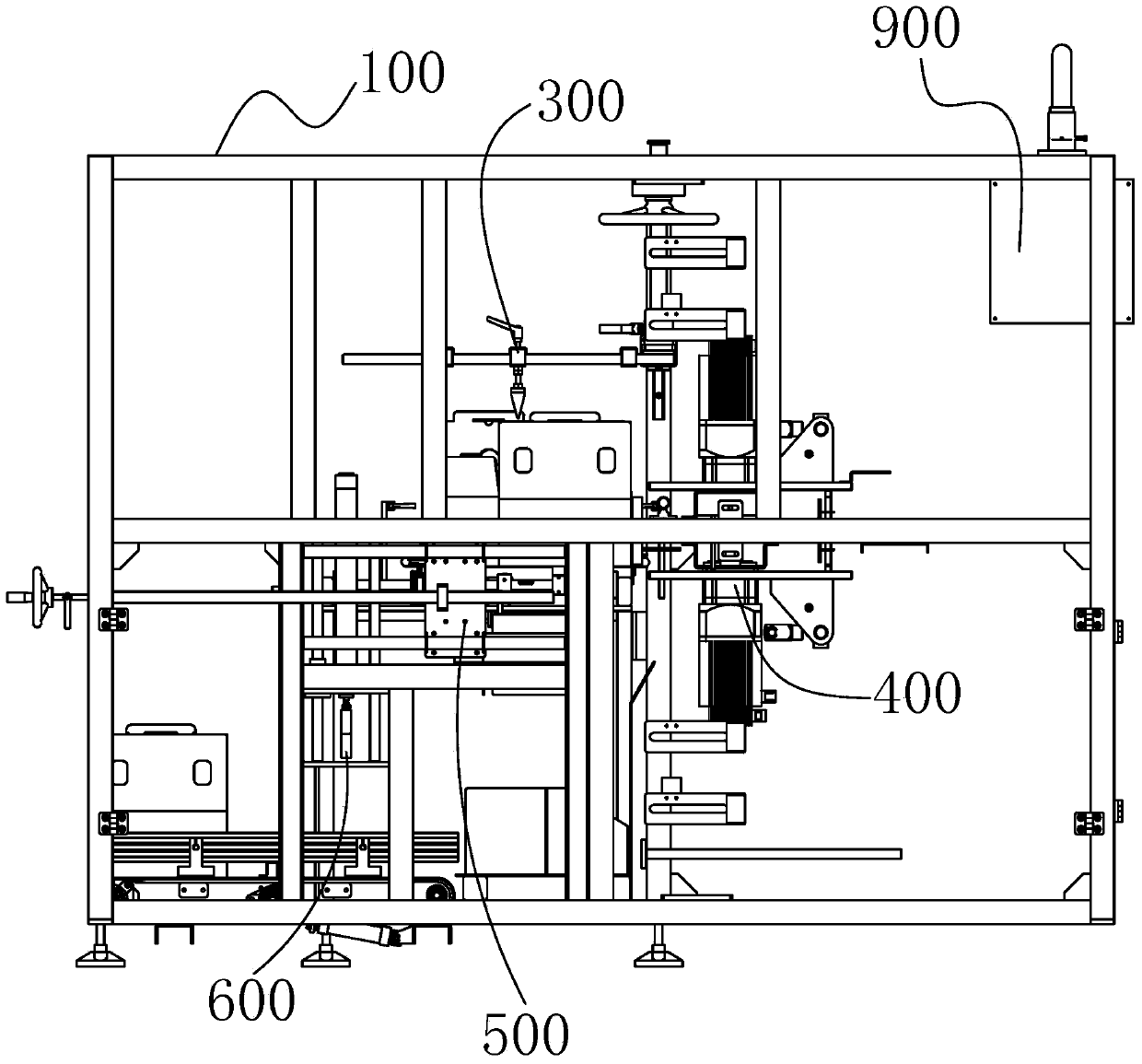

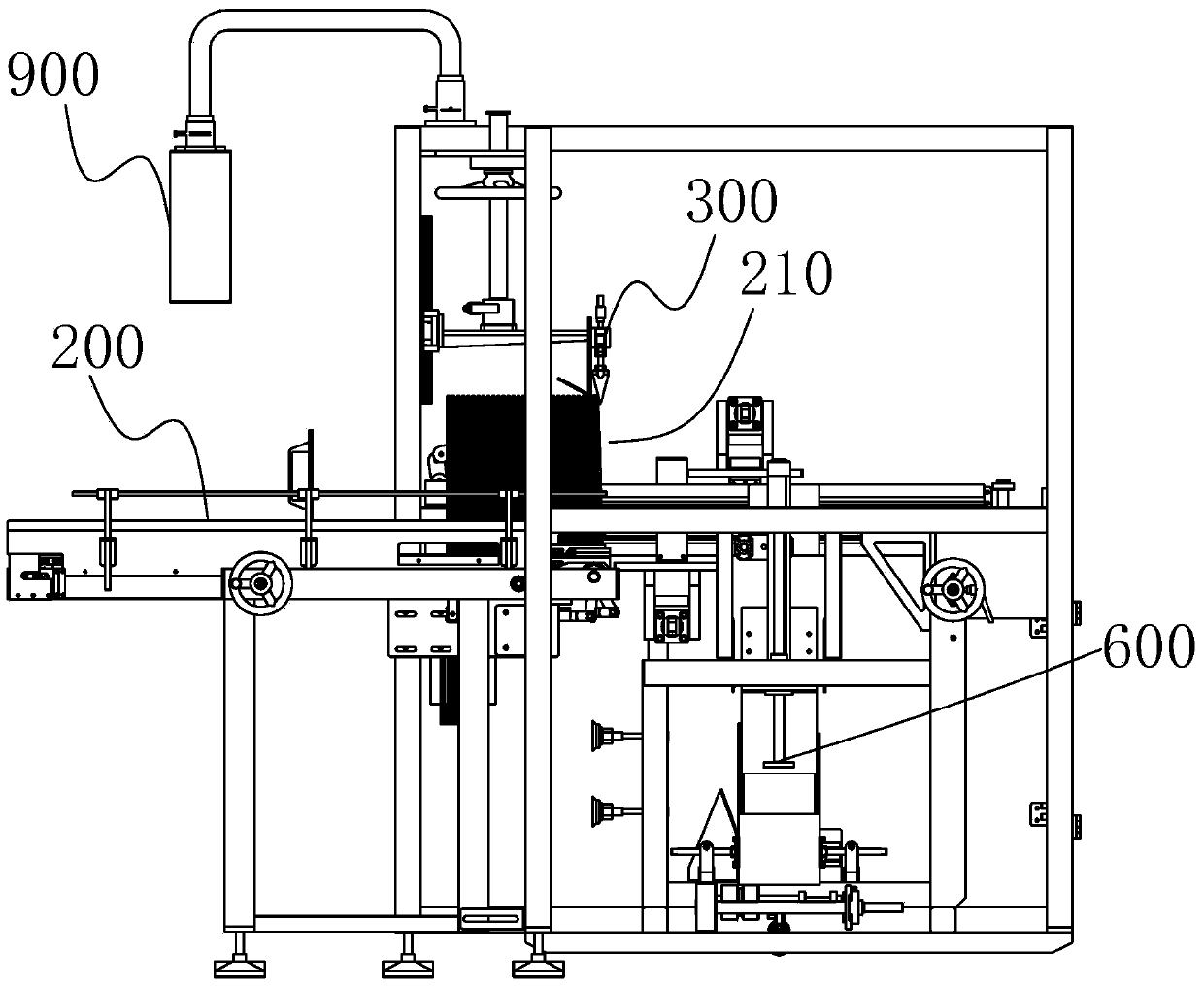

[0045] This embodiment proposes a gift box high-speed forming machine, which includes: a frame 100, a storage group system 200 for storing box cardboard, a blocking system 300 for blocking the output of the box cardboard, and Suction box system 400 that sucks out the carton board and stretches it to form a box body, guide box conveying system 500 used to transport the box body to different stations, and used to press the inner bottom surface of the box body so that it can be locked automatically L...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com