Preparation device for powder convenient to load and used for manufacturing ceramics, as well as using method thereof

A system and ceramic technology, applied in the field of powder preparation devices for ceramic manufacturing, can solve problems such as dust pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

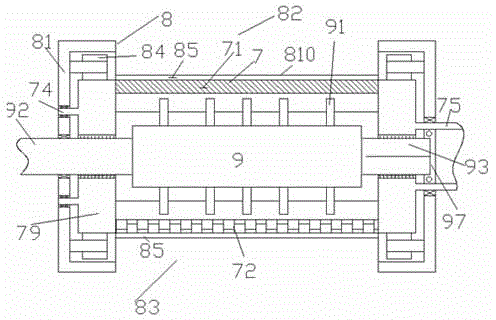

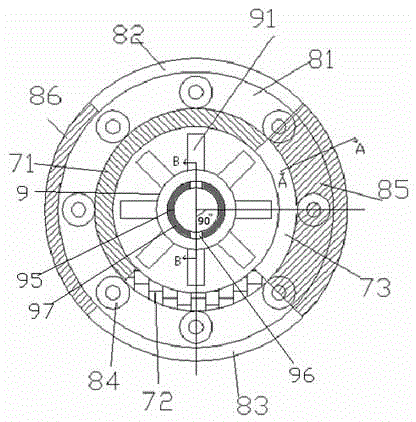

[0017] Combine below Figure 1-5 The present invention will be described in detail.

[0018] The powder preparation device for ceramic manufacturing that is easy to load according to the embodiment includes an external fixed cylinder 8, an internal rotatable cylinder 7, and a crushing execution shaft assembly 9, and the external fixed cylinder 8 is provided with The two end walls 81 and the connecting wall 810 between the two end walls 81, each of the two end walls 81 is provided with a plurality of support rollers 84 distributed along the circumferential direction, the connecting wall 810 is provided with a loading port 82 with an opening facing upwards and a powder outlet 83 with an opening facing down. Both the loading port 82 and the powder outlet 83 extend along the longitudinal direction of the cylinder, and the connecting wall 810 is loaded in the circumferential direction. Between the mouth 82 and the powder outlet 83 are respectively a left connecting wall 86 and a r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com