Hydraulic component integrated testing device and machining method thereof

A technology of integrated testing and hydraulic components, applied in the direction of fluid pressure actuation device, fluid pressure actuation system test, mechanical equipment, etc., can solve the problems of complex operation, arrangement, pressure measurement port dispersion, etc., to reduce production cost, operation Convenience and efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

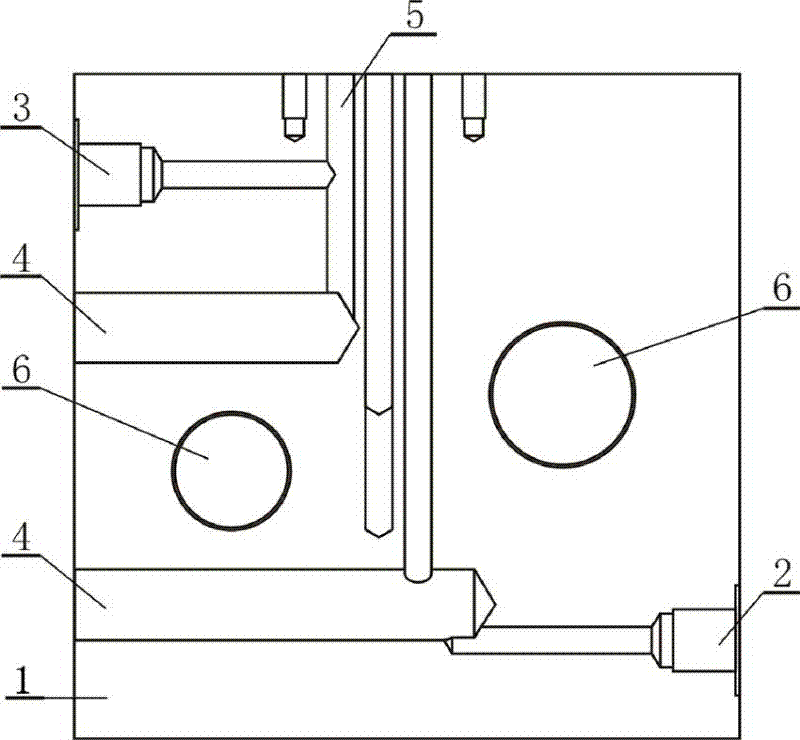

[0016] figure 1 It shows the three-dimensional structure of the pressure measurement integrated block in the prior art. Since the auxiliary test port 3 and the pressure measurement channel 4 adopt an orthogonal connection channel 5, the main test port and the auxiliary test port can only be set on the opposite side, and cannot be set on the same side. side, which brings great inconvenience to production and maintenance.

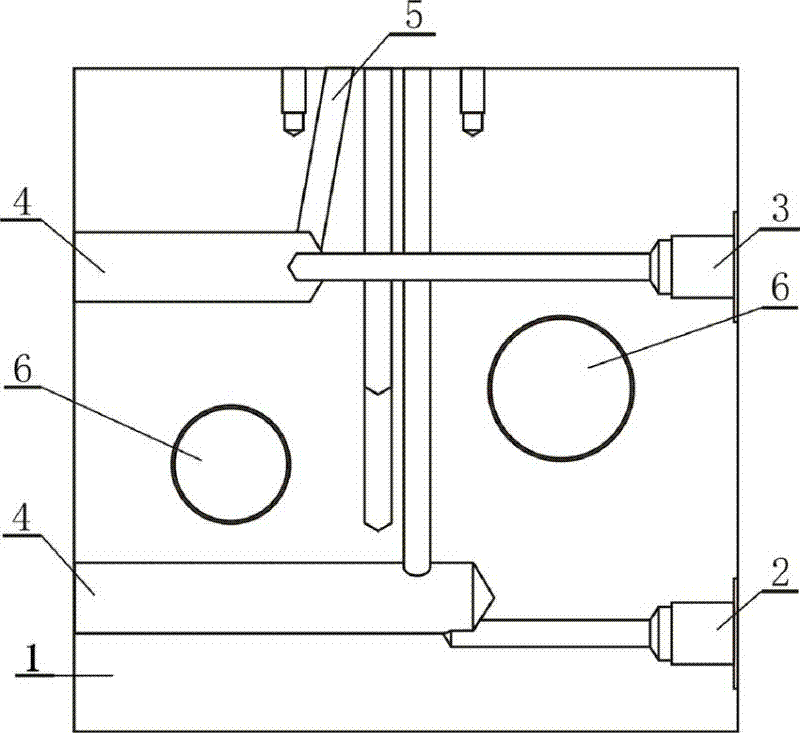

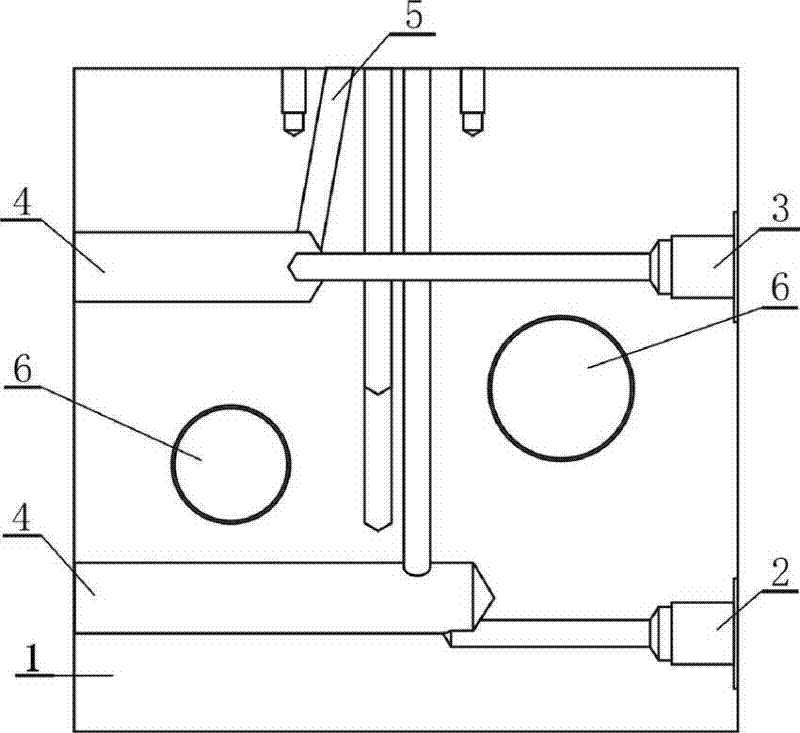

[0017] figure 2 The three-dimensional structure of the pressure measuring integrated block of the present invention is shown, including an integrated block 1, a pressure measuring channel 4, and a test port. The integrated block 1 is provided with a main test port ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com