Conical spring

A conical spring, a single technology, applied in the direction of spring/shock absorber, coil spring, mechanical equipment, etc., can solve the problems of poor safety and low flexibility, and achieve the effect of avoiding injury and smooth elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

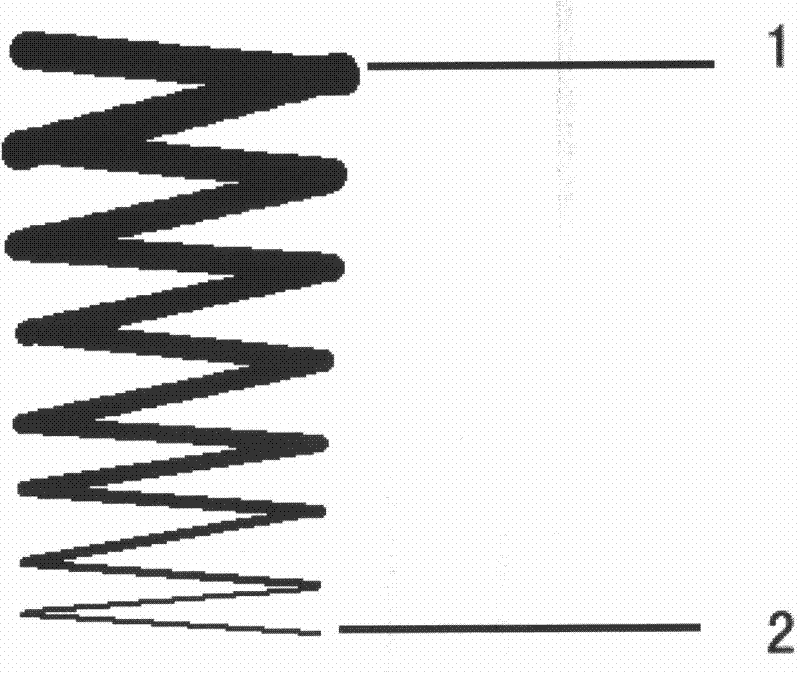

Embodiment 1

[0018] A conical spring, the spring is a single material, the cross-sectional area of the spring gradually decreases from the spring top 1 to the spring bottom 2; the elastic coefficient of the spring is 21N / m from the elastic coefficient of the spring top 1, and the spring bottom The elastic coefficient of 2 is 1N / m, and the length of the spring is 20cm. The elastic coefficient of the spring changes linearly from the spring top 1 to the spring bottom 2, that is, kL=1+L*k2; L is the length of the spring from the spring bottom 2 , k2 is the elastic coefficient of spring bottom 2.

[0019] When a force of 1N is used to apply pressure to the spring, the elasticity of the spring is F=k*x, F is the spring force of the spring, and x is the deformation of the spring. It can be seen that the spring force of the spring increases gradually with the deformation of the spring. This increase is caused not only by an increase in spring deformation but also by an increase in the spring con...

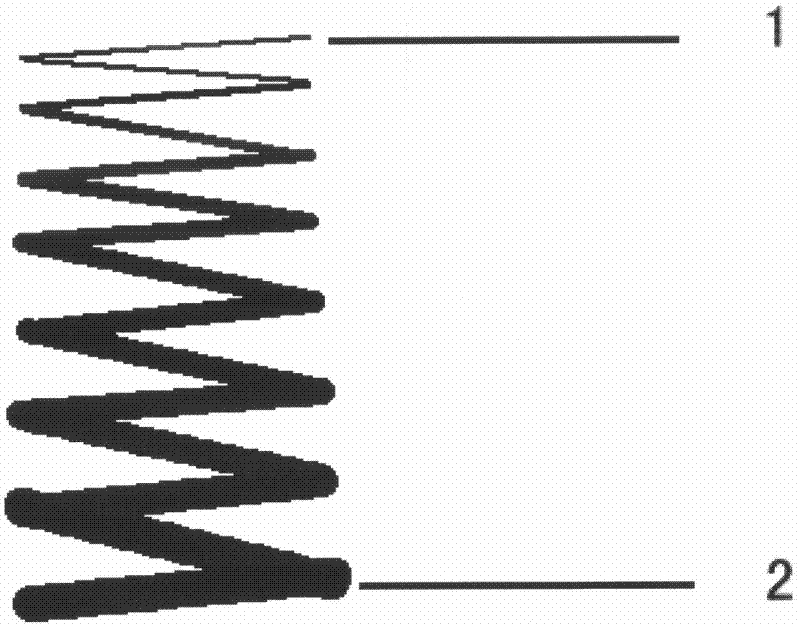

Embodiment 2

[0021] A conical spring, the spring is a single material, the cross-sectional area of the spring gradually increases from the spring top 1 to the spring bottom 2; the elastic coefficient of the spring is 1N / m from the spring top 1 to the spring bottom 2 The elastic coefficient of the spring is 21N / m, and the length of the spring is 20cm. The elastic coefficient of the spring changes linearly from the spring top 1 to the spring bottom 2, that is, kL=1+L*k1; L is the length of the spring from the spring top 1, k1 is the spring constant of spring top 1.

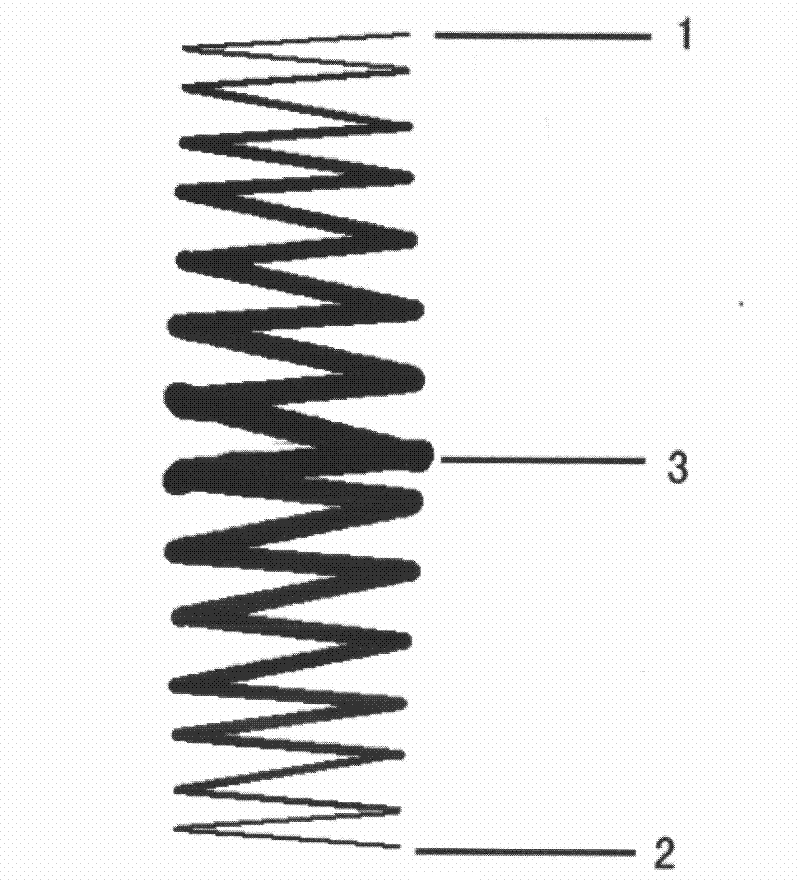

Embodiment 3

[0023] A kind of conical spring, this spring is a single material, the cross-sectional area of this spring first increases and then decreases from spring top 1 to spring bottom 2; the elastic coefficient of this spring is 1N / m from the elastic coefficient of spring top 1, The elastic coefficient of the spring bottom 2 is 1N / m, the elastic coefficient of the spring middle 3 is 21N / m, the length of the spring is 40cm, and the elastic coefficient of the spring changes linearly from the spring top 1, the spring middle 3 to the spring bottom 2, namely kL =1+L*k1, or kL=1+L*k2, L is the length of the spring from the spring top 1 or the spring bottom 2, k1 is the elastic coefficient of the spring top 1, and k2 is the elastic coefficient of the spring bottom 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic coefficient | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com