Gas storage tank comprising a liquid sealant

A fluid sealing material and gas storage technology, applied in gas processing/storage purposes, gas/liquid distribution and storage, fluid processing, etc., can solve problems such as hydrogen leakage, sealing adhesive deterioration, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The following descriptions of the embodiments are for explanation only, and cannot be used to limit the present invention and its application or use.

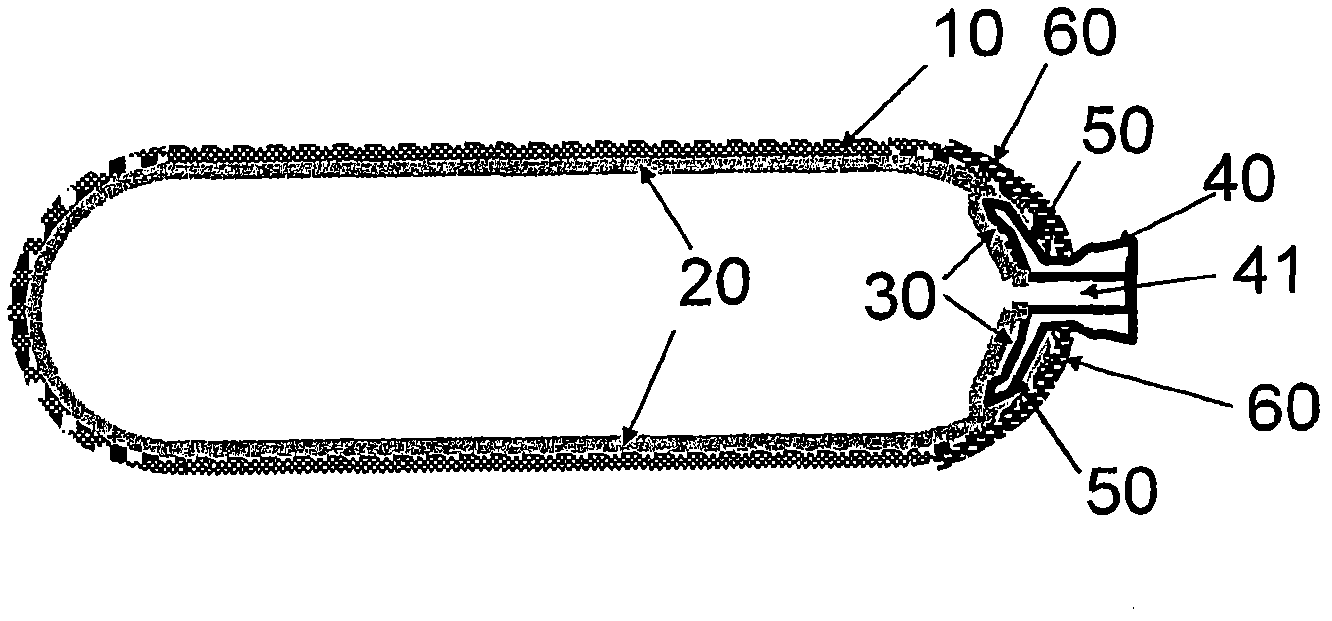

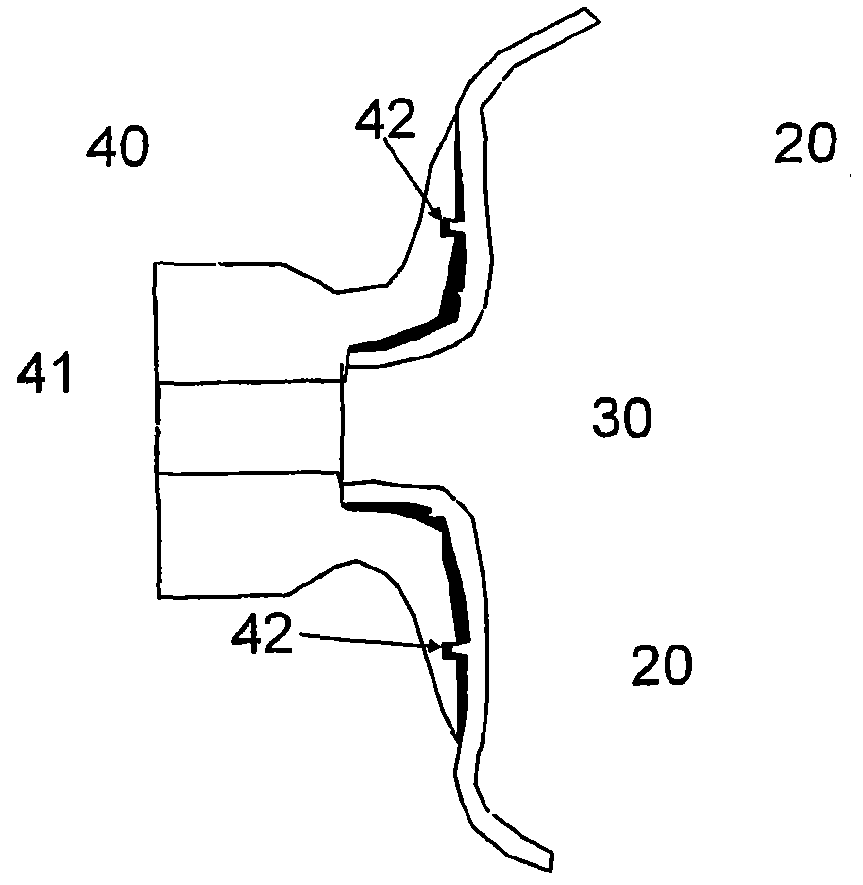

[0036] In high pressure applications, gas storage tanks can be configured as spherical or cylindrical, usually with hemi-spherical ends (domes), although other tank geometries are possible. The tank may comprise an inner bladder formed by an airtight inner liner layer, which is protected by an outer structural layer. The boss can be used to reliably connect the inner liner and the outer structural layer at the booster valve port of the tank shell to prevent gas leakage between the liner and the shell. There may be more than one boss in the gas storage tank. Typically there is a bore section within the boss to provide safe and reliable gas communication with the inflation source, gas consumer and pressure / temperature sensor.

[0037] figure 1 is a sectional view of a gas storage tank according to one embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com