Oscillating mechanism for fan heater

A technology for heaters and synchronous motors, used in lighting and heating equipment, fluid heaters, etc., can solve the problems of not being able to protect the power cord well, and difficult to pass 750,000 shaking head tests, to improve service life and reduce wear and tear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

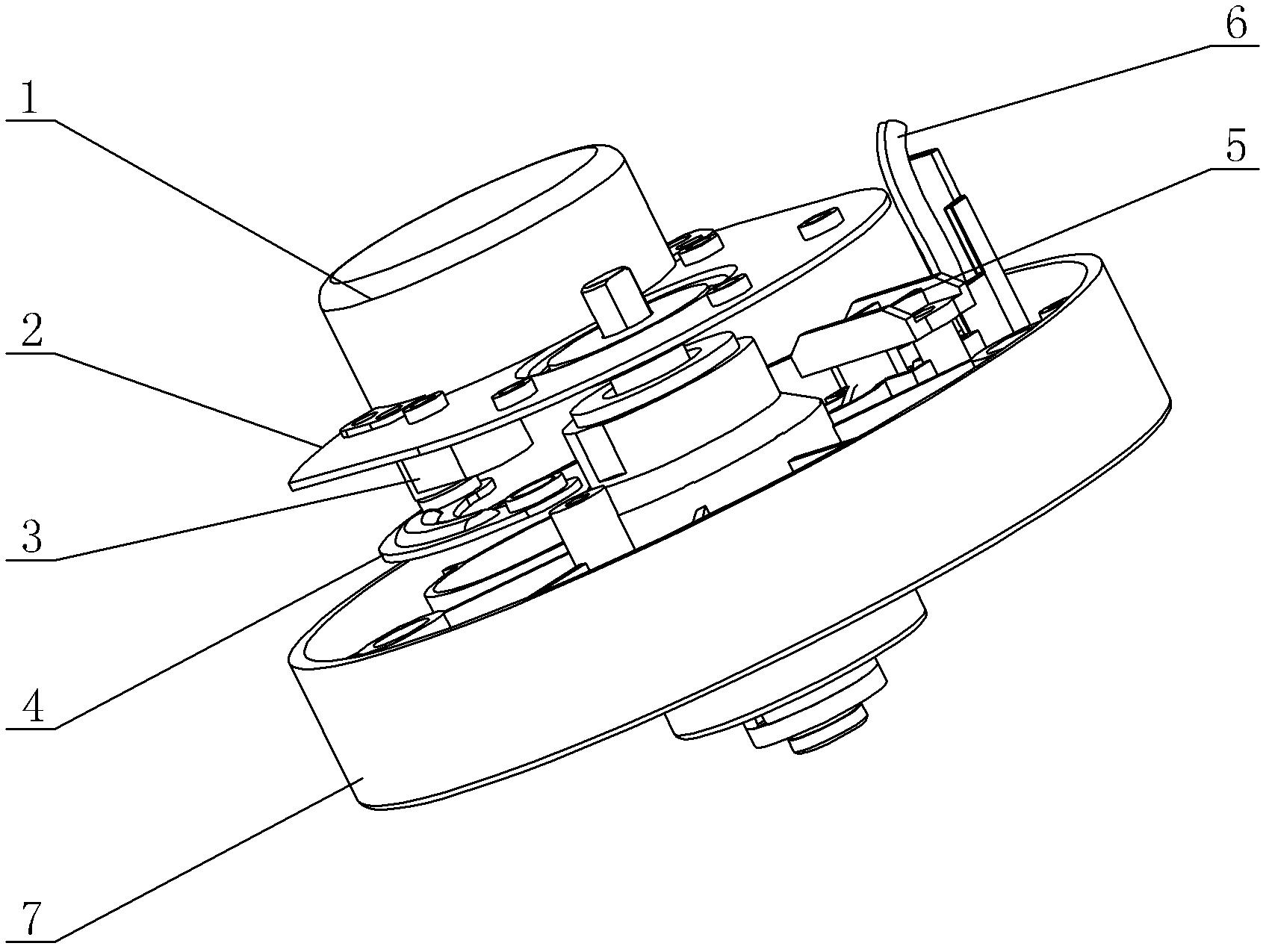

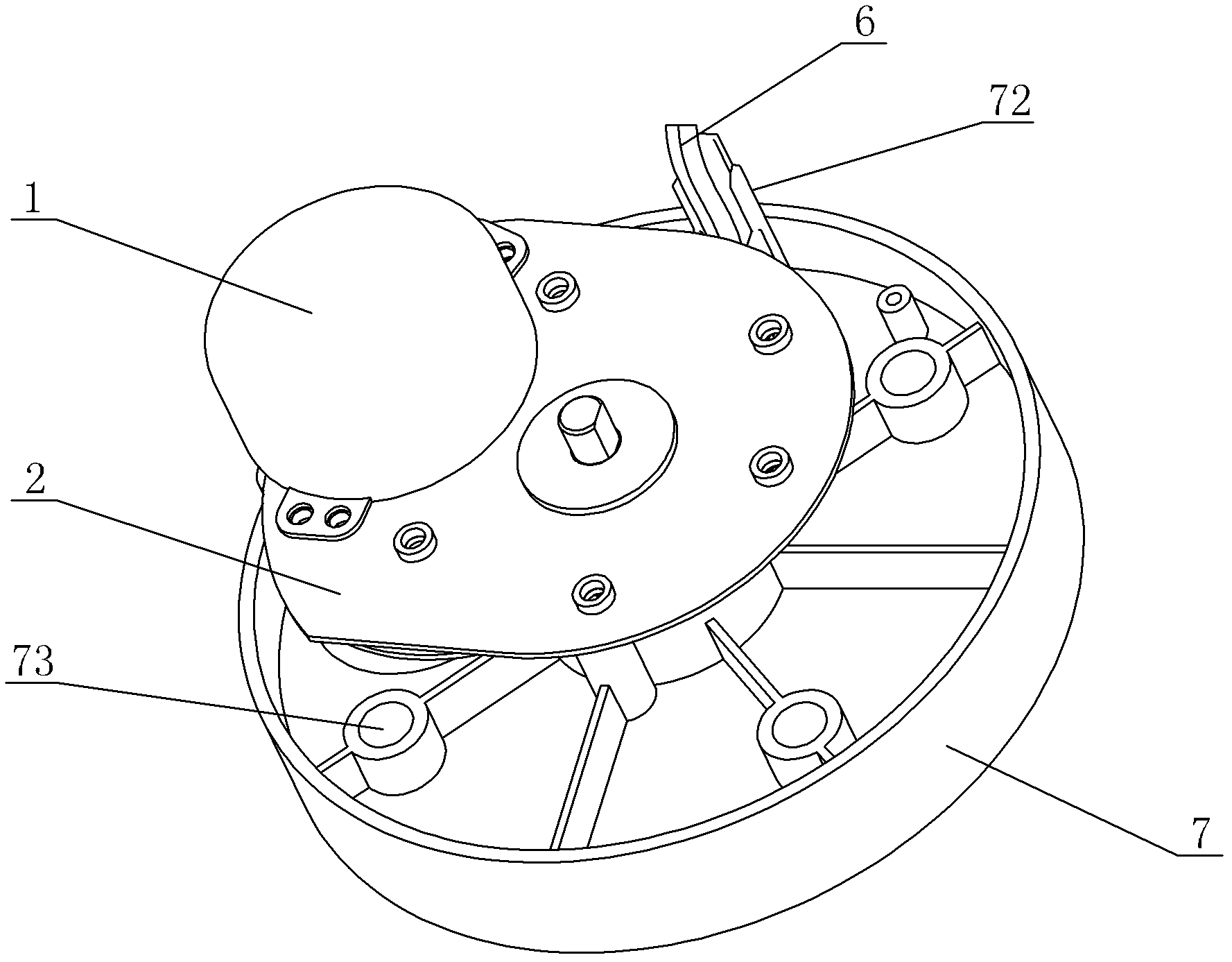

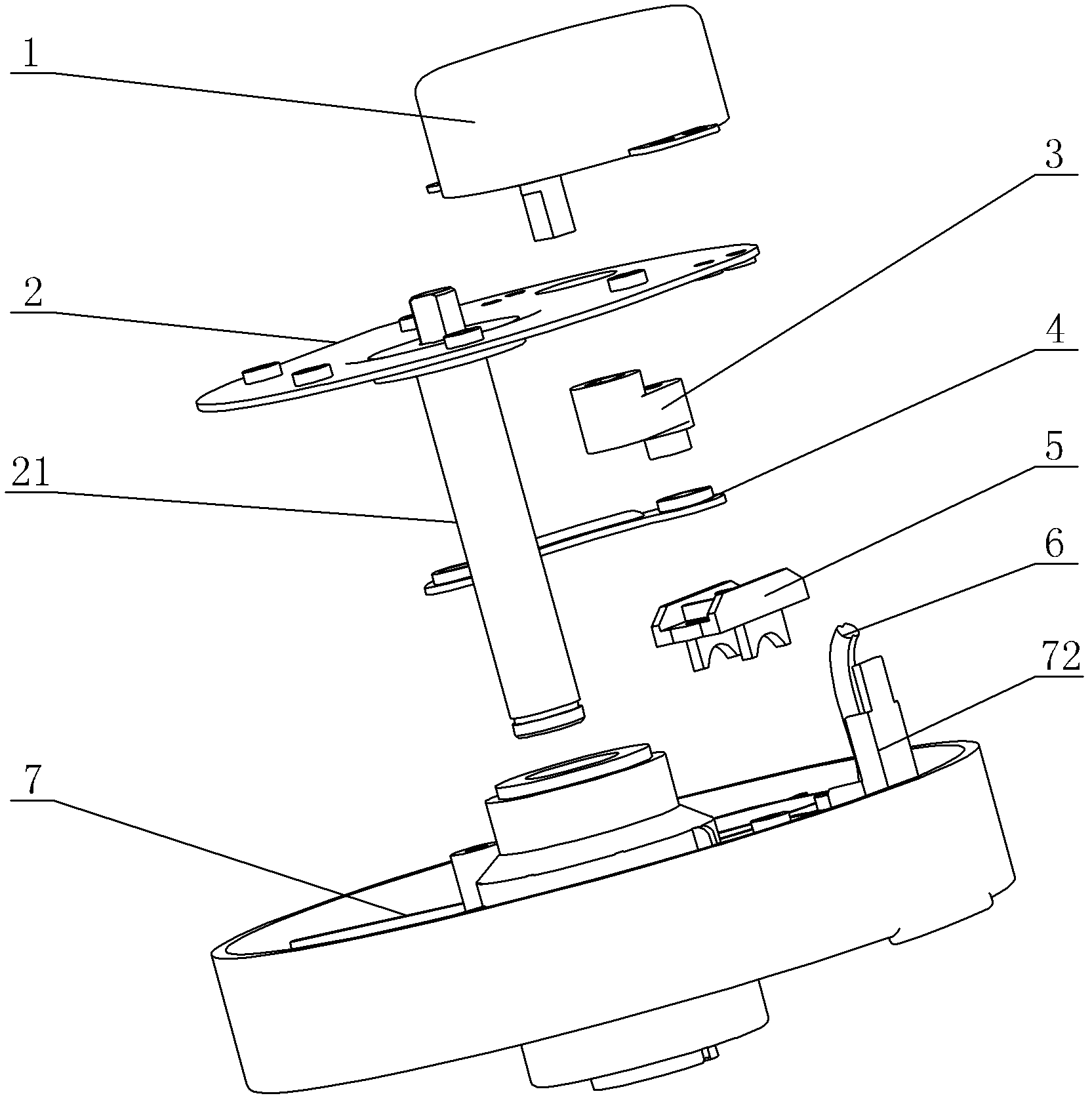

[0014] see Figure 1-Figure 4 , a heater shaking head mechanism, including a synchronous motor 1, a vertical shaft assembly 2, a crank 3, a connecting rod 4 and a power cord 6, wherein the synchronous motor 1 is fixed on the vertical shaft assembly 2, and the two ends of the crank 3 are respectively connected to the synchronous motor 1 and the One end of the connecting rod 4 is rotatably connected, and also includes an oscillating chassis 7 connected to the other end of the connecting rod 4 and a crimping box 5 installed on the oscillating chassis 7, and the power cord 6 is fixed on the oscillating chassis 7 through the crimping box 5. The oscillating head chassis 7 is installed on the vertical shaft 21 of the vertical shaft assembly 2, and the oscillating head chassis 7 takes the vertical shaft 21 as the rotation center. A plurality of nuts 73 for in-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com