Rotary encoder

A technology of rotary encoders and encoder discs, applied in the field of encoders, can solve the problems of encoders not being able to move, the number of pulses is limited, and the measurement accuracy is not high, so as to meet the requirements of high-precision and high-speed measurement and improve the reliability of data Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

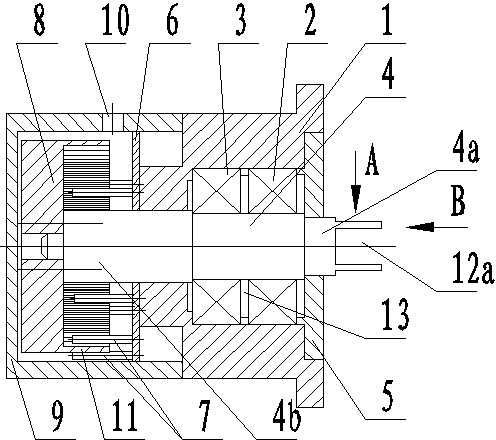

[0024] Such as Figure 1 to Figure 5 As shown, a rotary encoder includes a bearing housing 1, and the bearing housing 1 supports a rotating shaft 4 through first bearings 2 and second bearings 3 arranged at intervals. A bearing retaining ring 13 is arranged between the first bearing 2 and the second bearing 3.

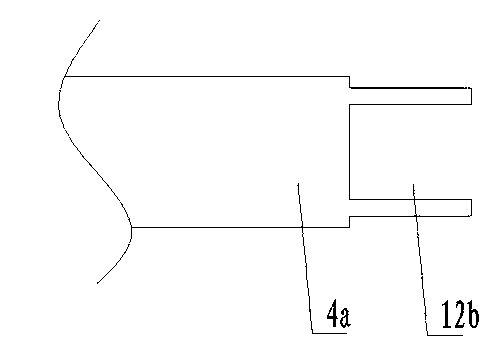

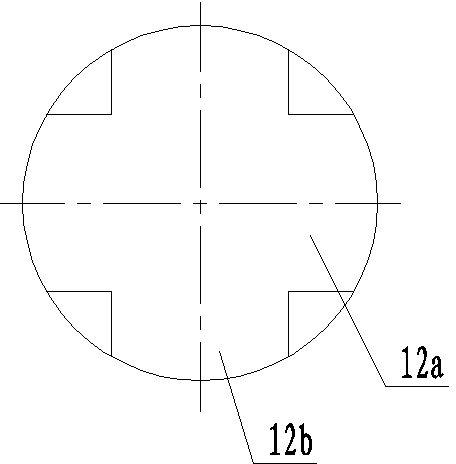

[0025] An end cover 5 is fixedly connected to the first end of the bearing housing 1 , and a circuit board 6 is fixedly connected to the end surface of the second end. The rotating shaft 4 is provided with a first connection groove 12a and a second connection groove 12b perpendicular to each other at the protruding end 4a of the end cover 5, so as to clamp it on the shaft parts of the rotating machine, and the encoder can be synchronized with it after being fixed. rotate.

[0026] In this embodiment, the circuit board 6 is directly fixedly connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com