Method For Controlling The Output Of Drink Component In Fully Automatic Coffee Machine

A fully automatic, coffee machine technology, applied in the direction of liquid flow control devices, coin-operated devices for controlling the distribution of fluid/granular materials from containers, beverage preparation devices, etc., which can solve the problem of insufficient cleaning of flow measurement devices, Problems such as high cleaning cost and infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

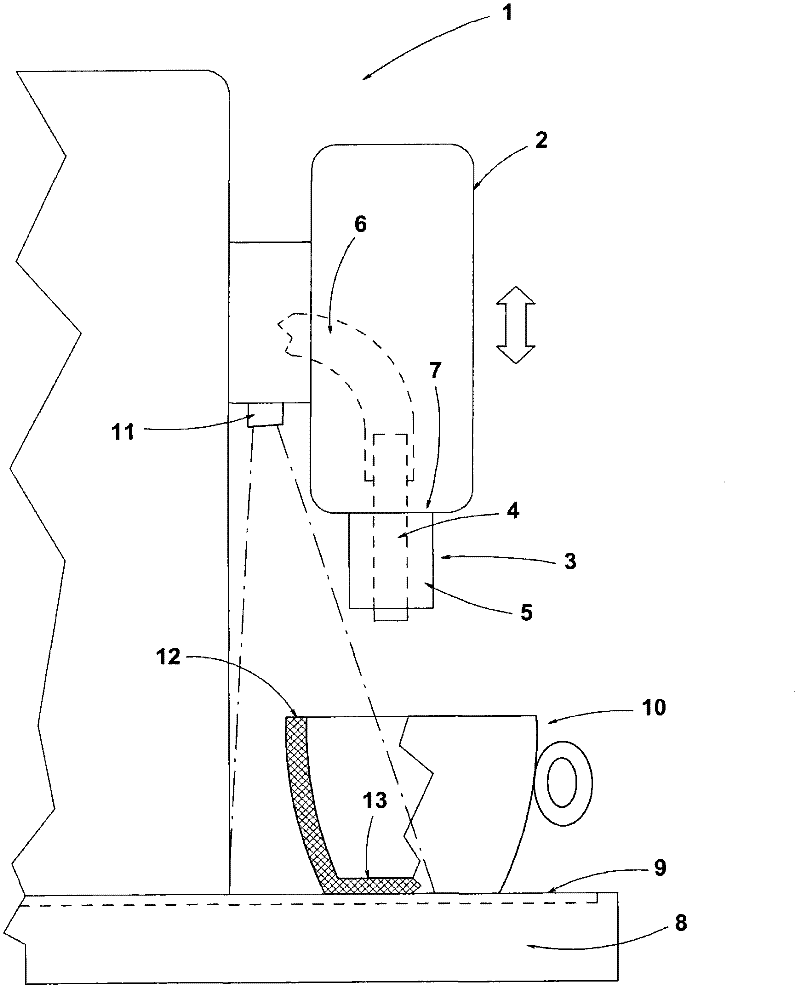

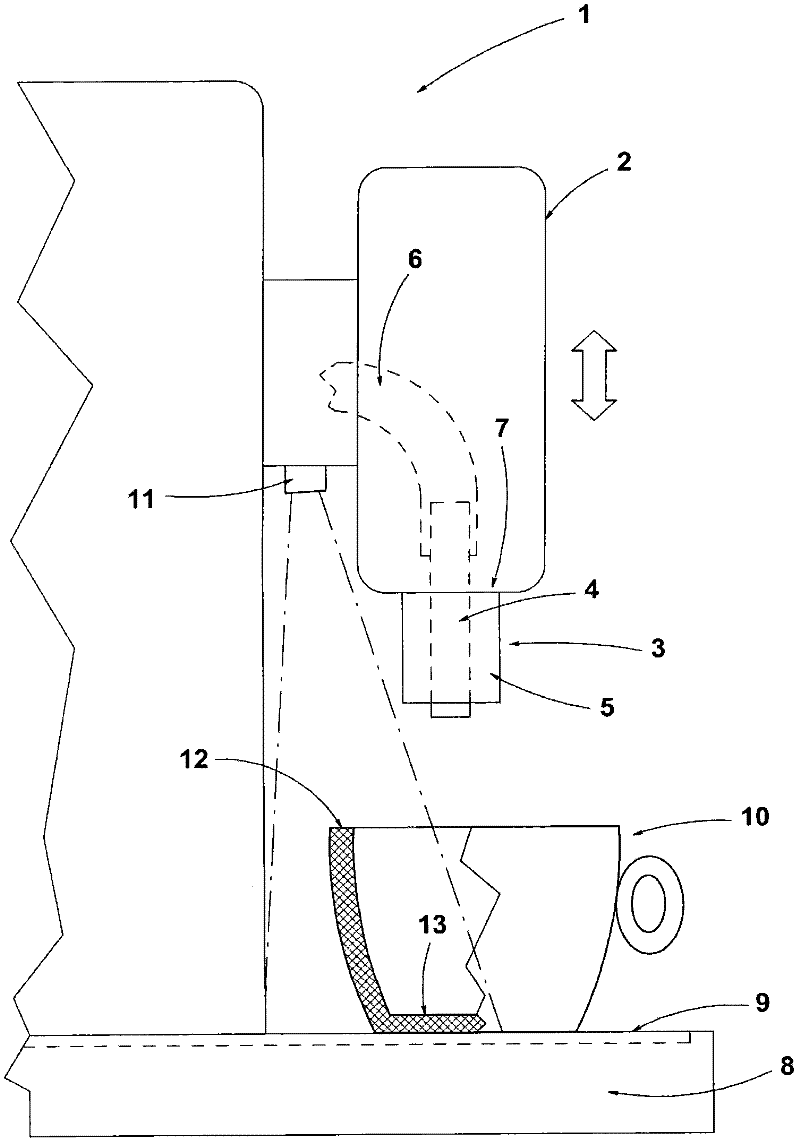

[0033] The fully automatic coffee machine 1 , which is not otherwise shown in detail, has an output device 2 through which the beverage components are output. The output mechanism 2 includes an output port 3 . The outlet 3 can be designed as a double outlet and comprises an inner channel 4 and an annular groove 5 surrounding the inner channel 4 . The inner channel 4 is formed of a tube, and a hose 6 is inserted above the tube inside the output mechanism 2 . This hose 6 is connected in a manner not described in detail to a jet pump with a milk frothing chamber arranged downstream. In this way, the inner channel 4 of the outlet 3 is used for the delivery of milk or milk froth. The annular groove 5 is used to output coffee. The annular groove 5 constitutes the outlet of a collector 7 arranged inside the output mechanism 2, into which the boiled coffee flows. Like the suction jet pump and the milk frothing chamber, the equipment necessary for the preparation of coffee is also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com