Self-control quantitative concrete production device and working method thereof

A technology for production equipment and concrete, which is applied in the direction of clay preparation equipment, unloading equipment, cement mixing equipment, etc., can solve the problems of insufficient automation, high safety hazards, and low work efficiency, so as to reduce the frequency of manual intervention and improve production Efficiency, reducing the effect of intermediate handling links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

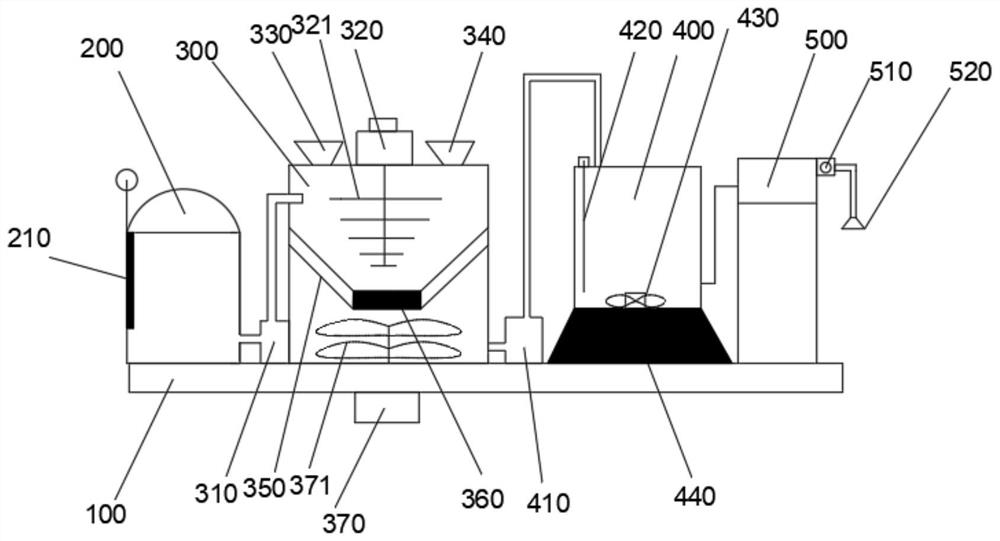

[0029] Such as figure 1The self-controlled quantitative concrete production device shown includes a base 100, a water storage tank 200, a water storage tank level gauge 210, a mixing tank 300, an outlet pump 310, a top stirring motor 320, a top stirrer 321, and a main material inlet Hopper 330, additive feed hopper 340, conical partition 350, electric valve 360, bottom stirring motor 370, bottom agitator 371, storage tank 400, storage tank feed pump 410, storage tank thermometer 420, storage tank Material tank agitator 430, material storage tank heating base 440, discharge pump 500, discharge pump flowmeter 510, discharge pipe 520; the base 100 is a rectangular metal base; the water storage tank 200, mixing tank 300, The storage tank 400 and the discharge pump 500 are sequentially placed on the base 100; the water storage tank 200 is a cylindrical container, and the inner wall of the water storage tank 200 is provided with the water storage tank level gauge 210; The water sto...

Embodiment 2

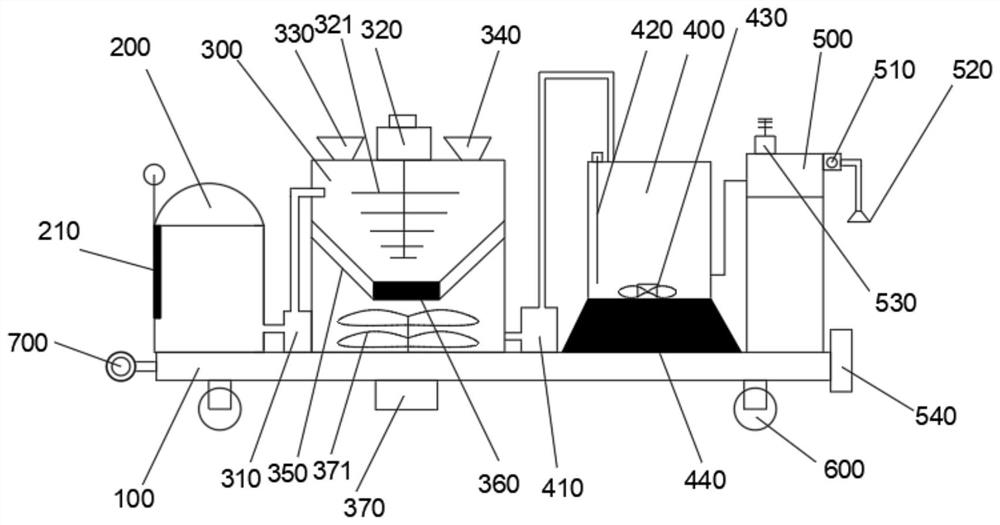

[0037] Such as figure 2 The self-controlled quantitative concrete production device shown includes a base 100, a water storage tank 200, a water storage tank level gauge 210, a mixing tank 300, an outlet pump 310, a top stirring motor 320, a top stirrer 321, and a main material inlet Hopper 330, additive feed hopper 340, conical partition 350, electric valve 360, bottom stirring motor 370, bottom agitator 371, storage tank 400, storage tank feed pump 410, storage tank thermometer 420, storage tank Material tank agitator 430, material storage tank heating base 440, discharge pump 500, discharge pump flowmeter 510, discharge pipe 520; the base 100 is a rectangular metal base; the water storage tank 200, mixing tank 300, The storage tank 400 and the discharge pump 500 are sequentially placed on the base 100; the water storage tank 200 is a cylindrical container, and the inner wall of the water storage tank 200 is provided with the water storage tank level gauge 210; The water s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com