Multi-oil cylinder axial loading system

An axial loading, oil cylinder technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of dead zone bearing test, limited adjustment range of loading force, inability to realize automatic adjustment of loading force, etc., to avoid dead zone and meet large load loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present invention will be specifically described below with reference to the accompanying drawings.

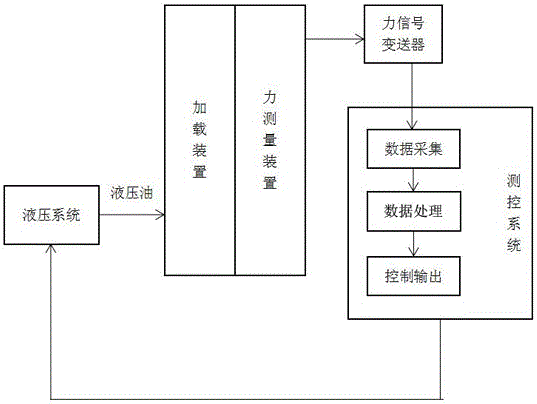

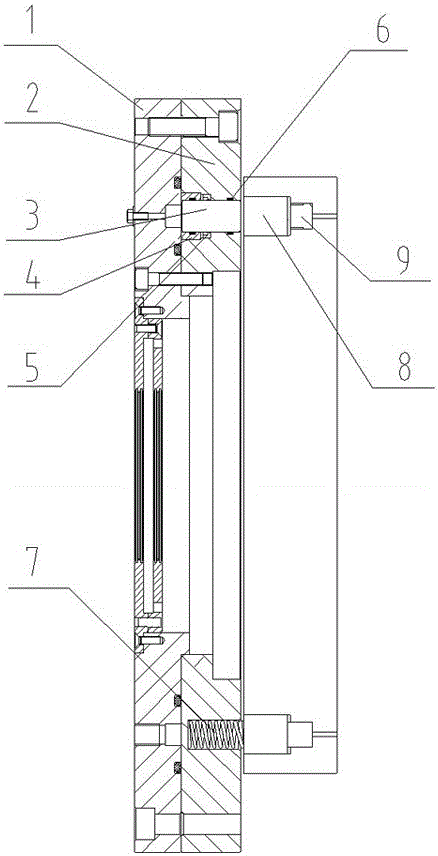

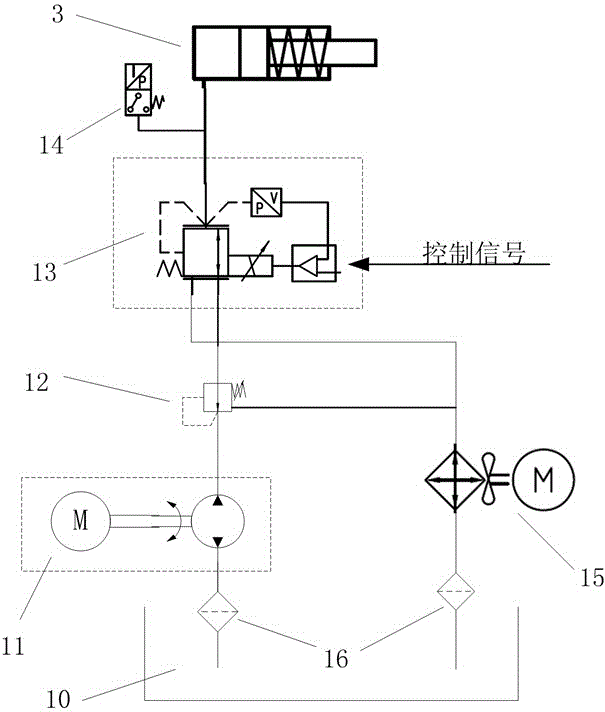

[0026] Such as Figures 1 to 3 As shown, a multi-cylinder axial loading system is composed of a hydraulic system, a loading device, a force transmission and measuring device, and a measurement and control system arranged in sequence. The measurement and control system is also connected to the hydraulic system in feedback to realize closed-loop control. The hydraulic system is used to provide driving force to the loading device, which is converted into a loading force by the loading device and applied to the force transmission and measurement device. The force transmission and measurement device transmits the loading force to the test piece while transmitting the loading force to the measurement and control system. After analysis and processing by the measurement and control system, the control signal is fed back to the hydraulic system to achieve the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com