Breakout prediction method for continuous casting

A technology of breakout and continuous casting, which is applied in the field of breakout prediction in the continuous casting process of slabs, can solve the problems of high false alarm rate, the friction signal is susceptible to various interferences, and false alarms, so as to reduce the number of false alarms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

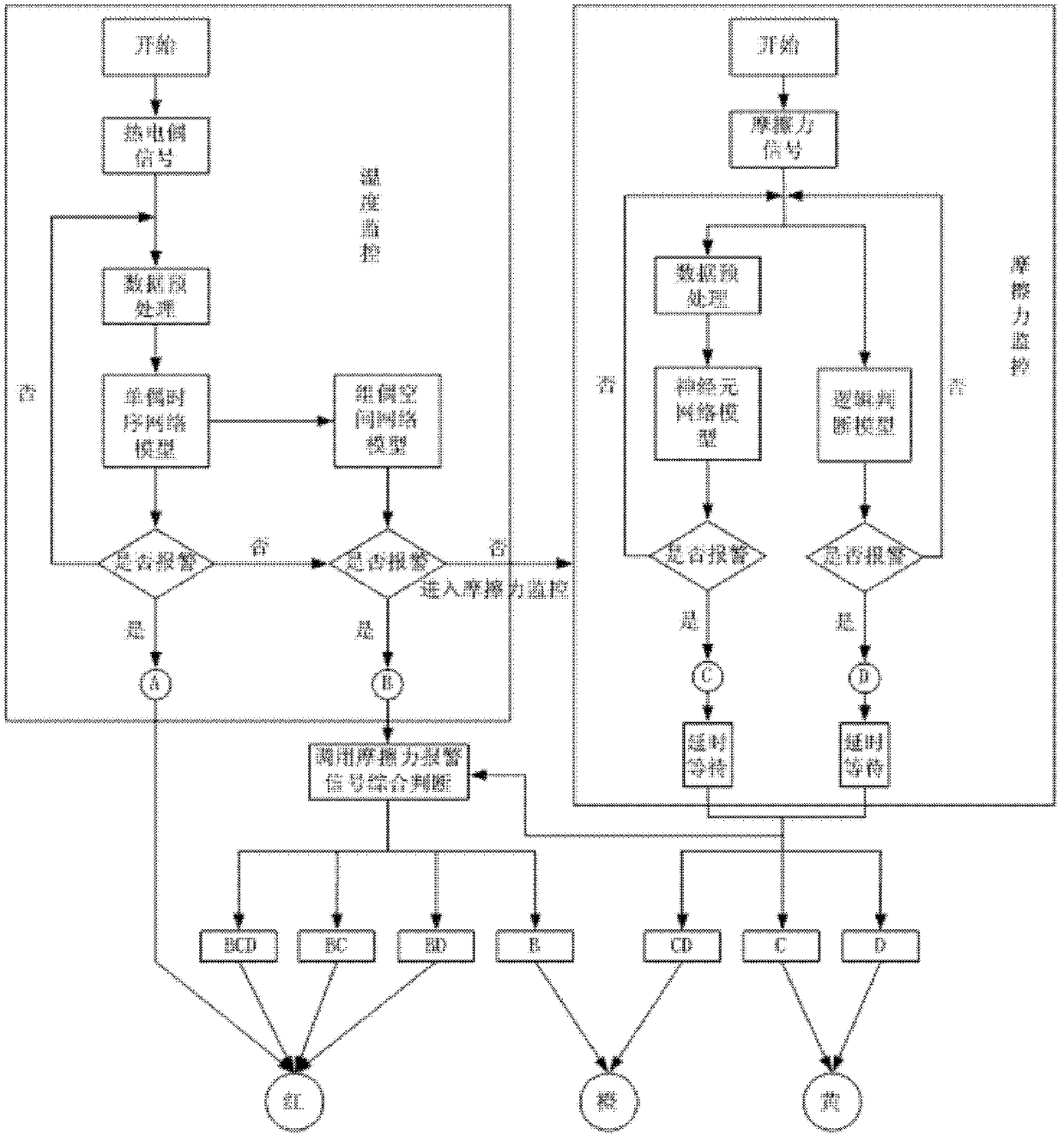

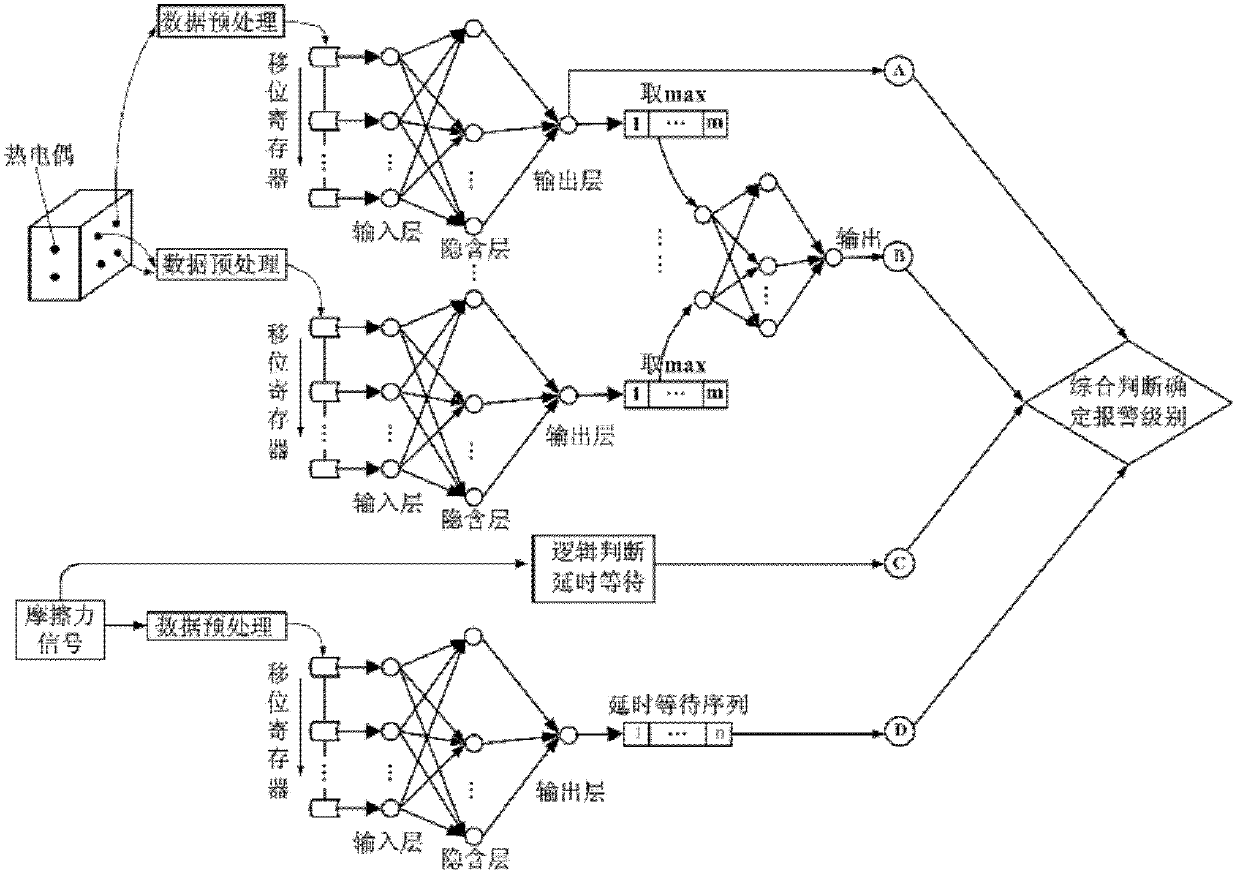

[0082] The coupling model establishment and application process is as follows:

[0083] 1. Data collection

[0084] The thermocouple temperature and hydraulic cylinder pressure value are periodically sampled. The thermocouple temperature sampling period is 2s, and the hydraulic cylinder pressure value sampling period is 50ms. The analog signal is converted into a digital signal through A / D conversion and sent to the computer for analysis.

[0085] 2. Data preprocessing

[0086] (1) Temperature data processing

[0087] Process the temperature data according to the formulas (1) and (2), the number n of the original sampling temperature in this example 0 =15, the stable threshold value of the temperature sampling sequence λ=25°C.

[0088] (2) Friction data processing

[0089] According to the formula (8) to process the friction data, the number n of the original sampling friction in this example 1 =20.

[0090] 3. Establishment of the sub-model of the breakout prediction mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com