Combined production line

A production line and combined technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of bulkiness, cost, inconvenience, etc., and achieve the effects of cost saving, convenient transportation, convenient and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

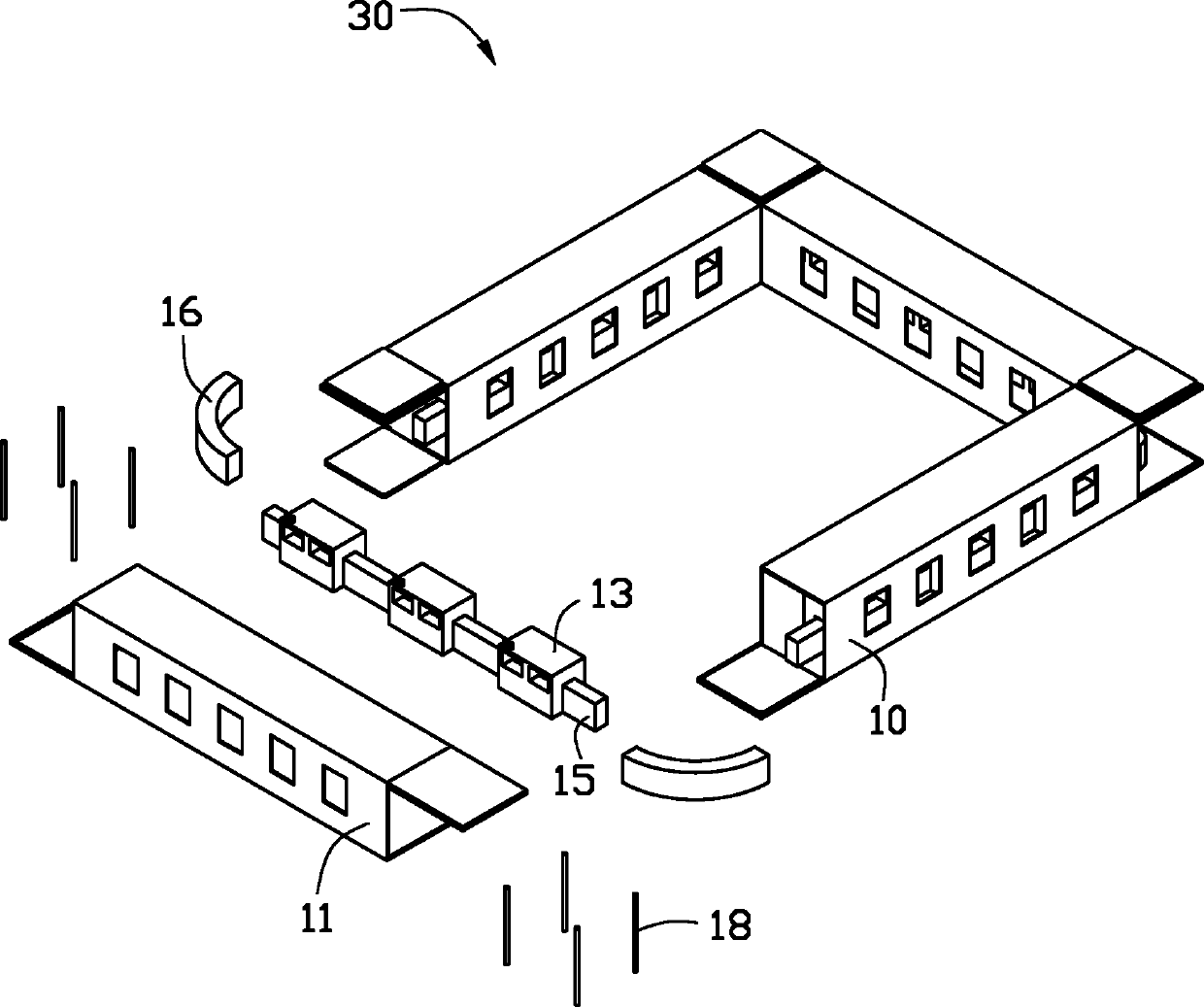

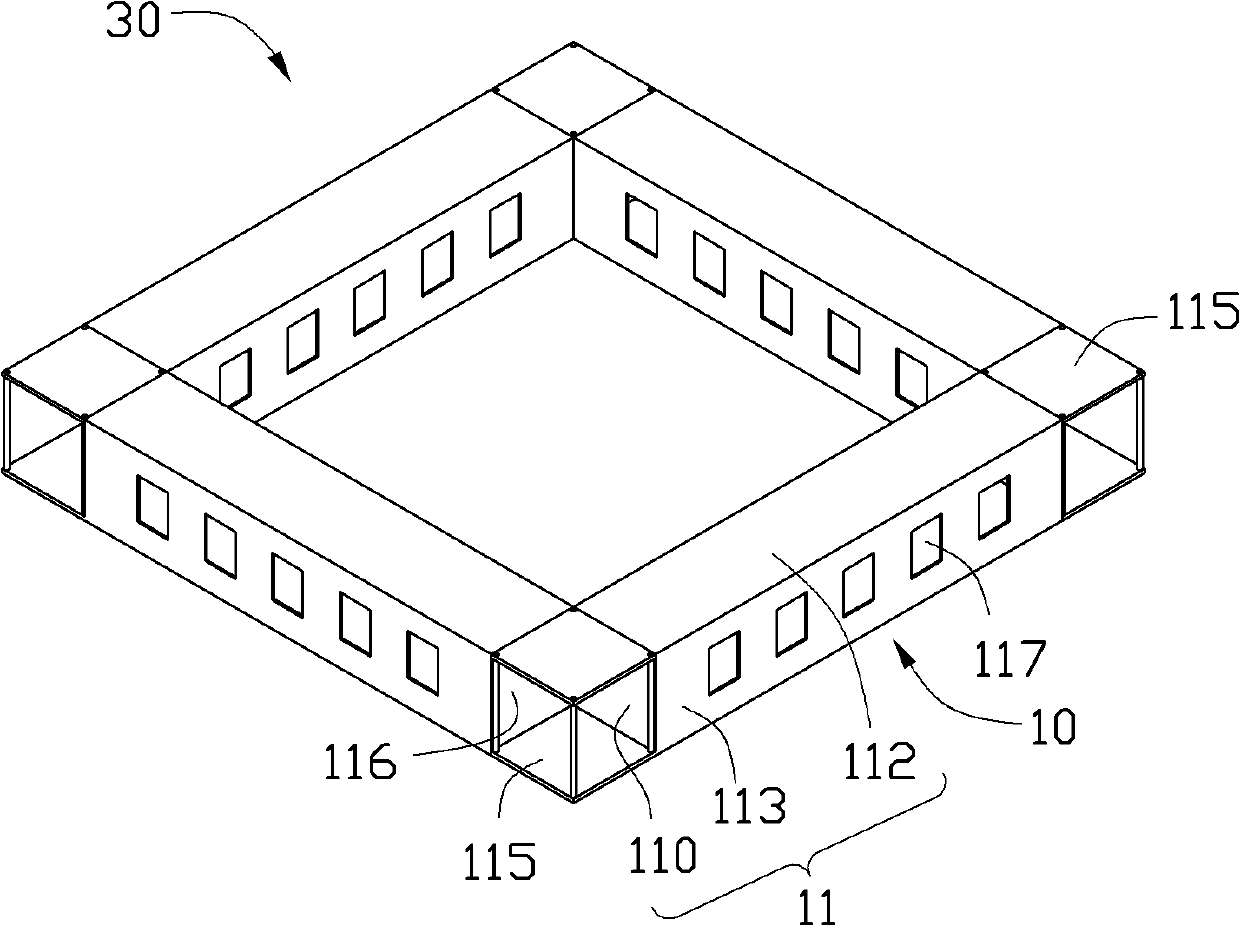

[0016] Please also refer to figure 1 and figure 2 , shows a combined production line 30 in the first embodiment of the present invention, which includes four container units 10 connected end-to-end to form a single-layer ring-shaped overall structure.

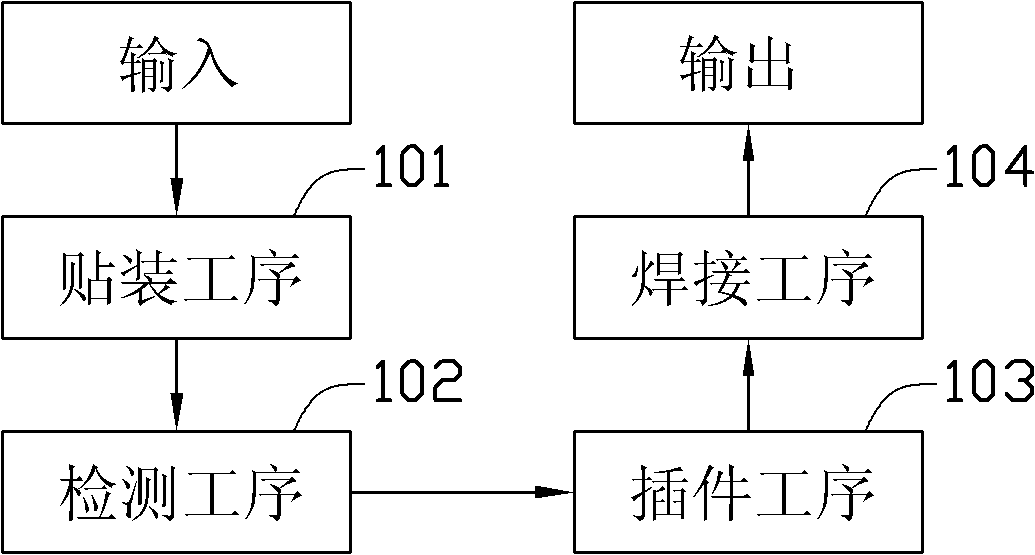

[0017] Each container unit 10 includes a hollow rectangular box 11 , a plurality of machines 13 accommodated in the box 11 and a conveyor belt 15 connected between the machines 13 . The box body 11 includes a rectangular flat bottom plate 110, a top plate 112 parallel to the bottom plate 110, left and right side plates 113 respectively connected to the opposite sides of the bottom plate 110 and the top plate 112, and respectively connected to the bottom plate 110. The front and rear side doors 115 at opposite ends of the top plate 112. The bottom board 110 , the top board 112 , and the left and right side boards 113 jointly form a storage space 116 for accommodating the machine 13 and the conveyor belt 15 . The front side d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com