Light-weight bolster for urban rail trains

A lightweight technology for urban rail trains, applied in railway car body parts, bogies, transportation and packaging, etc., can solve problems such as compact design and layout of unfavorable equipment and components, shortening service life, and increasing the weight of corbels, etc. Achieve the effect of improving the stress concentration problem of corbels, reducing the degree of stress damage and increasing the running speed of the train

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

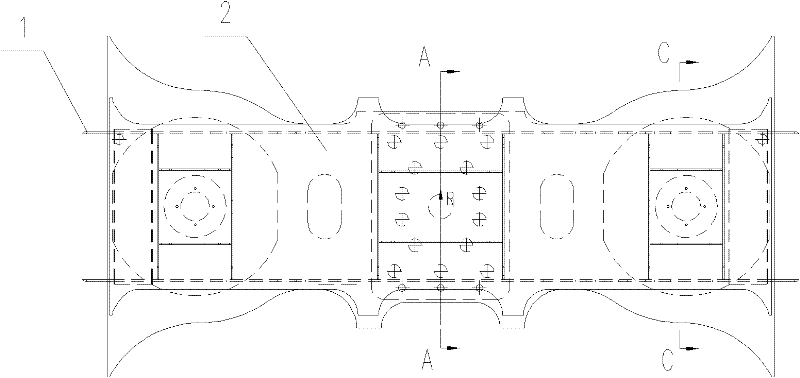

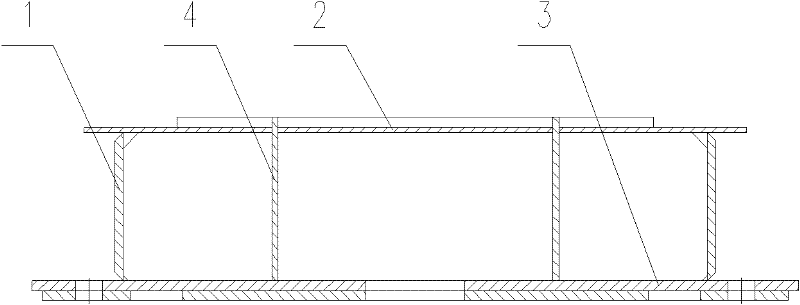

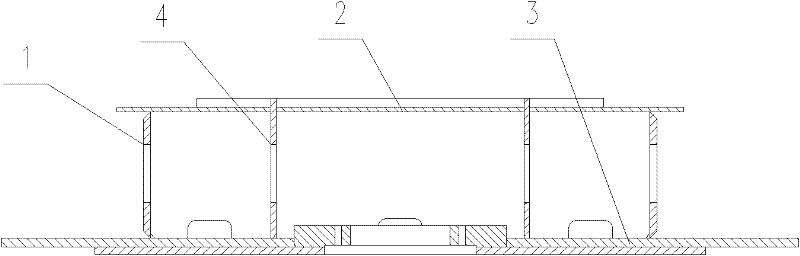

[0034] Example 1, such as Figure 1 to Figure 4 As shown, the lightweight corbel for urban rail trains mainly includes a web 1 , an upper cover 2 , a lower cover 3 , a rib 4 , an empty spring backing 5 and a traction pin backing 6 . in,

[0035] A web 1 is arranged vertically between the upper cover plate 2 and the lower cover plate 3 .

[0036] Protruding arc portions 10 are provided on the sides or ends of the upper cover plate 2 and the lower cover plate 3 , respectively.

[0037] The web 1, the upper cover plate 2 and the lower cover plate 3 form a mouth-shaped box structure by welding.

[0038] An empty spring backing plate 5 for bearing the vertical load of the whole vehicle and a traction pin backing plate 6 for bearing the longitudinal load of the whole vehicle are welded on the surface of the lower cover 3. Several circular holes 9 are arranged.

[0039] Several ribs 4 are welded between the web 1 , the upper cover 2 and the lower cover 3 to increase local rigidit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com