Coupler box

A technology of coupler box and coupler mounting plate, which is applied to railway car body parts, railway vehicle coupling accessories, railway couplings, etc. , the traction beam increases stress damage and other problems, and achieves the effect of reducing self-weight, improving stress concentration, and improving structural rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

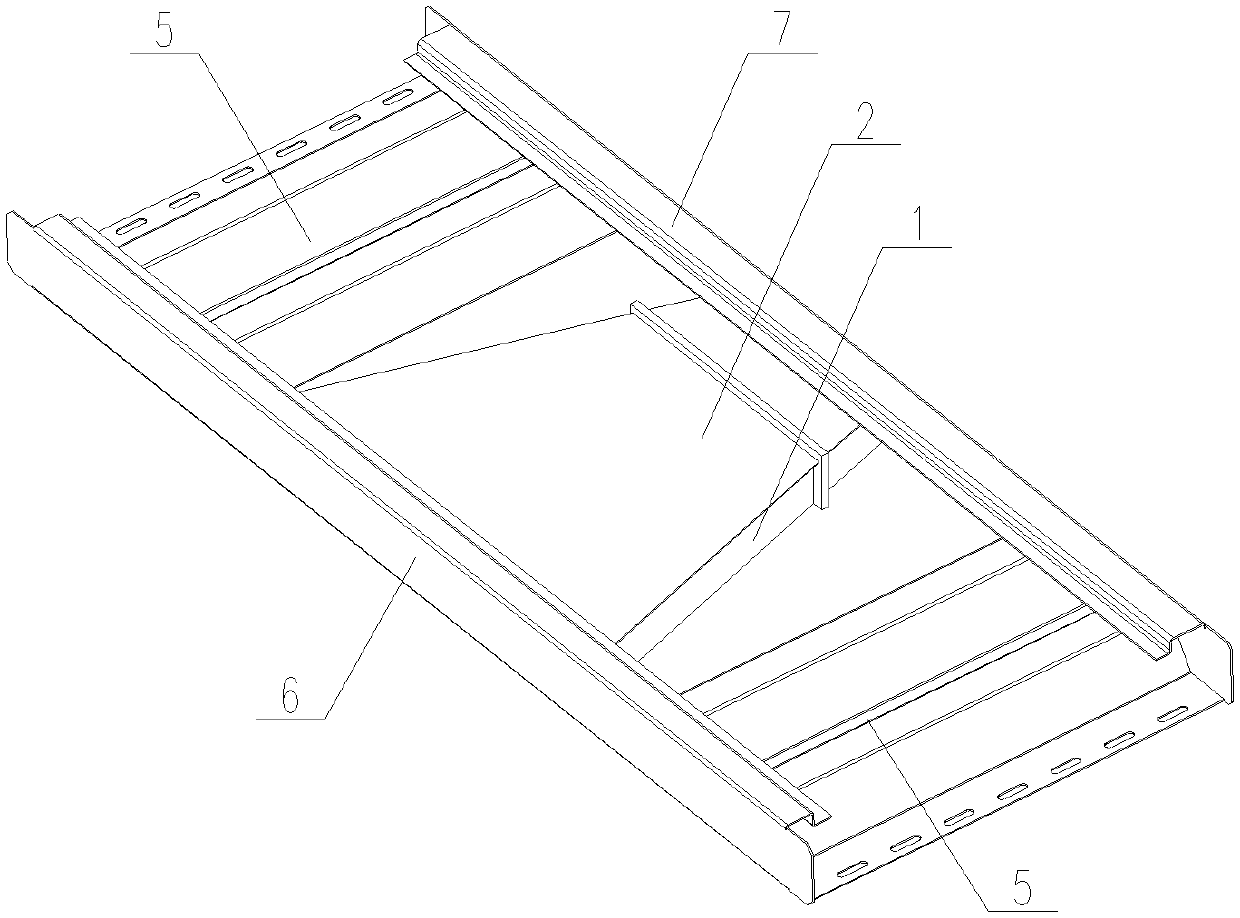

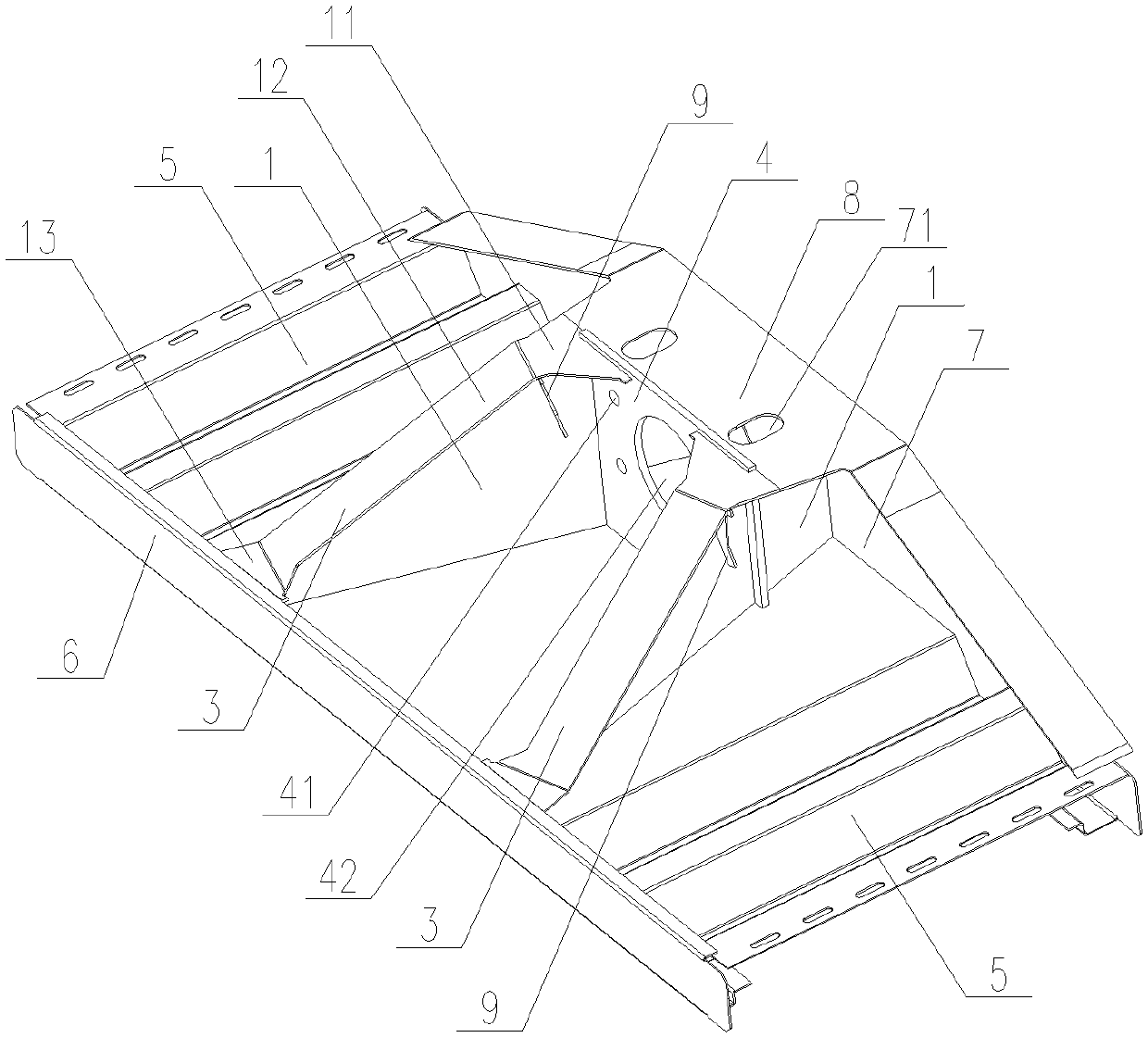

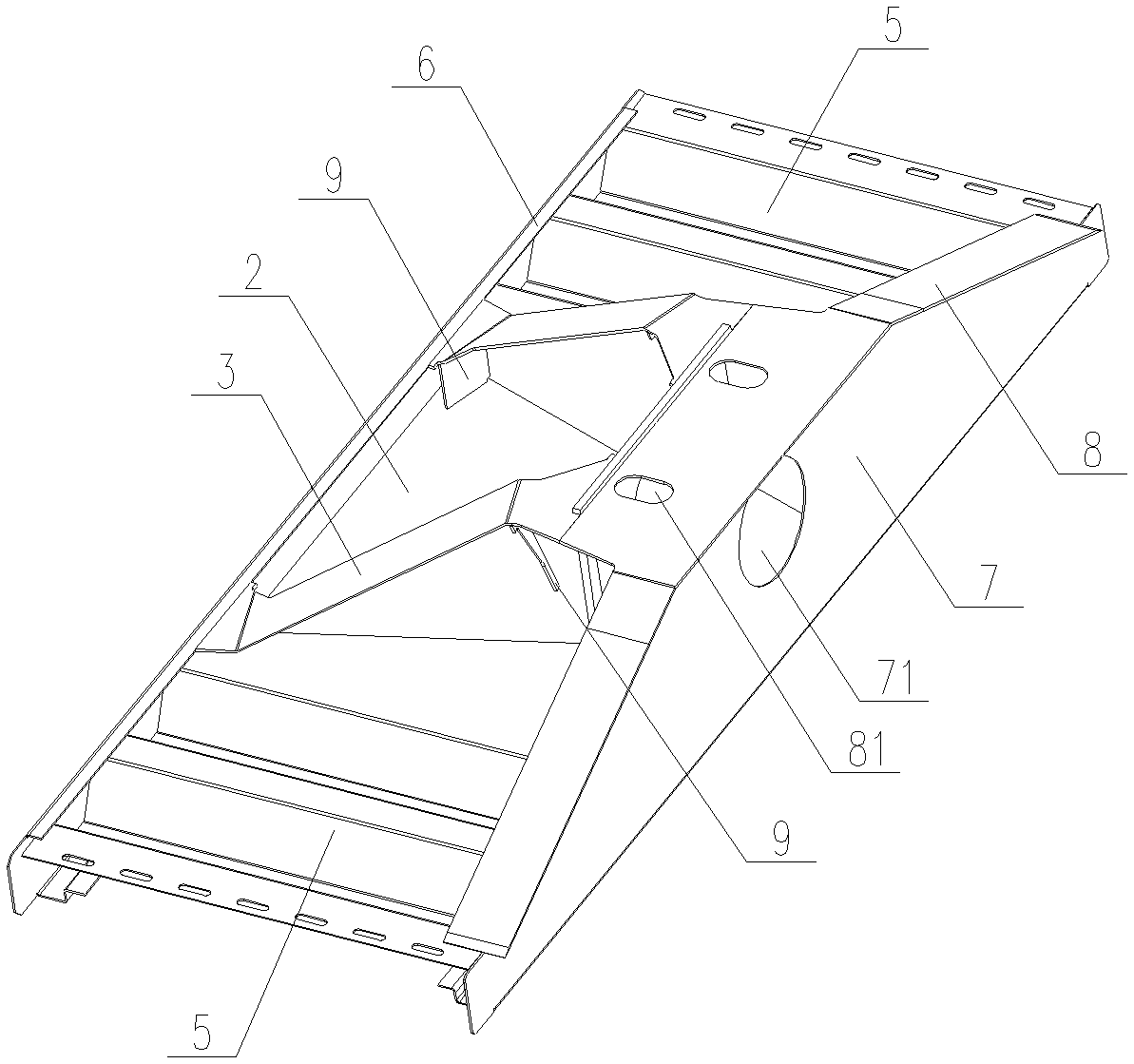

[0050] Example 1, such as Figure 1 to Figure 4 As shown, the laser-welded stainless steel coupler box mainly includes a pair of side webs 1 , an upper cover 2 and a lower cover 3 welded in sequence.

[0051] Among them, the web 1 is welded with the upper cover plate 2 and the lower cover plate 3 to form an integral box-shaped structure whose cross-sectional area gradually decreases from one end to the other end;

[0052] Coupler mounting plate 4, side corrugated plate 5, buffer beam 6 and rear end beam 7 are welded around the box structure;

[0053] The rear end beam 7 has an outwardly protruding rear end beam lower cover plate 8 which is respectively connected with the lower cover plate 3 and the coupler mounting plate 4 .

[0054] In the box-shaped structure composed of the web 1 , the upper cover plate 2 and the lower cover plate 3 , the cross-sectional area of the end connected to the buffer beam 6 is the smallest, and the cross-sectional area of the end connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com