Construction method for reducing frost heaving effect borne by derrick foundation

A construction method and basic technology, which is applied in the direction of basic structure engineering, sinking, shaft equipment, etc., can solve the problems of energy loss, large investment, and shrinking the circle diameter of freezing holes, so as to reduce the effect of frost heave and weaken the strength of frost heave Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

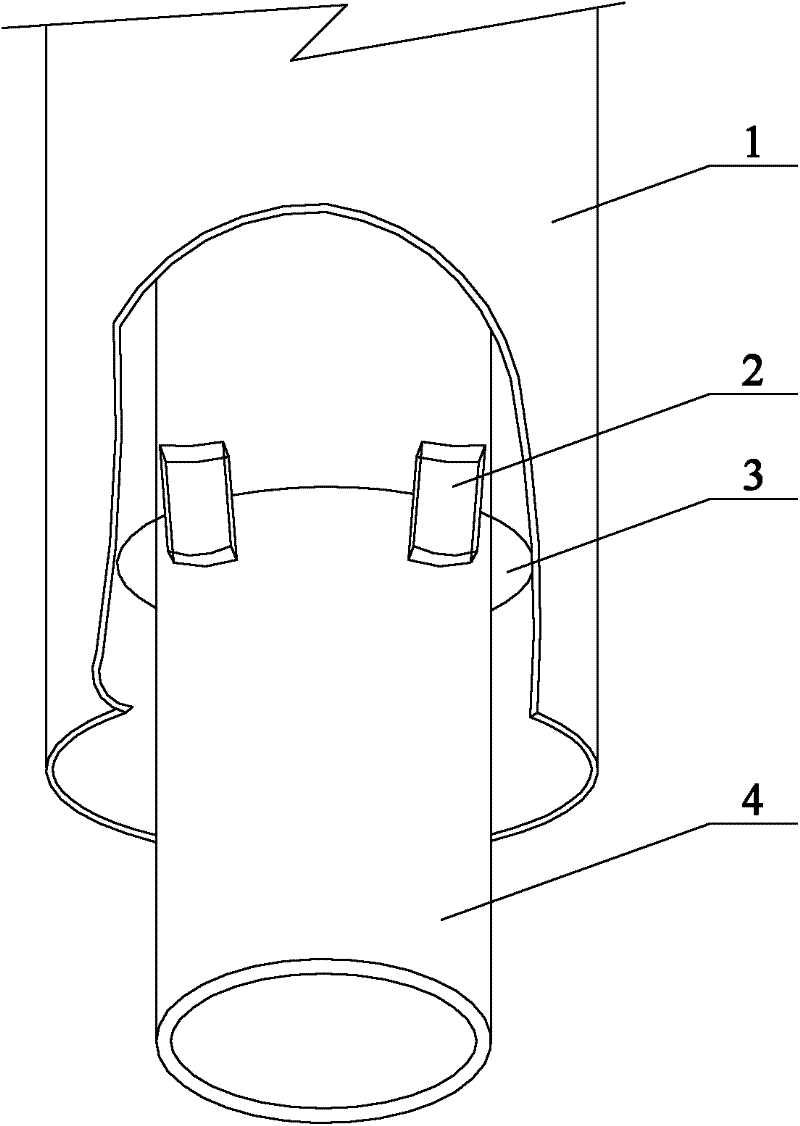

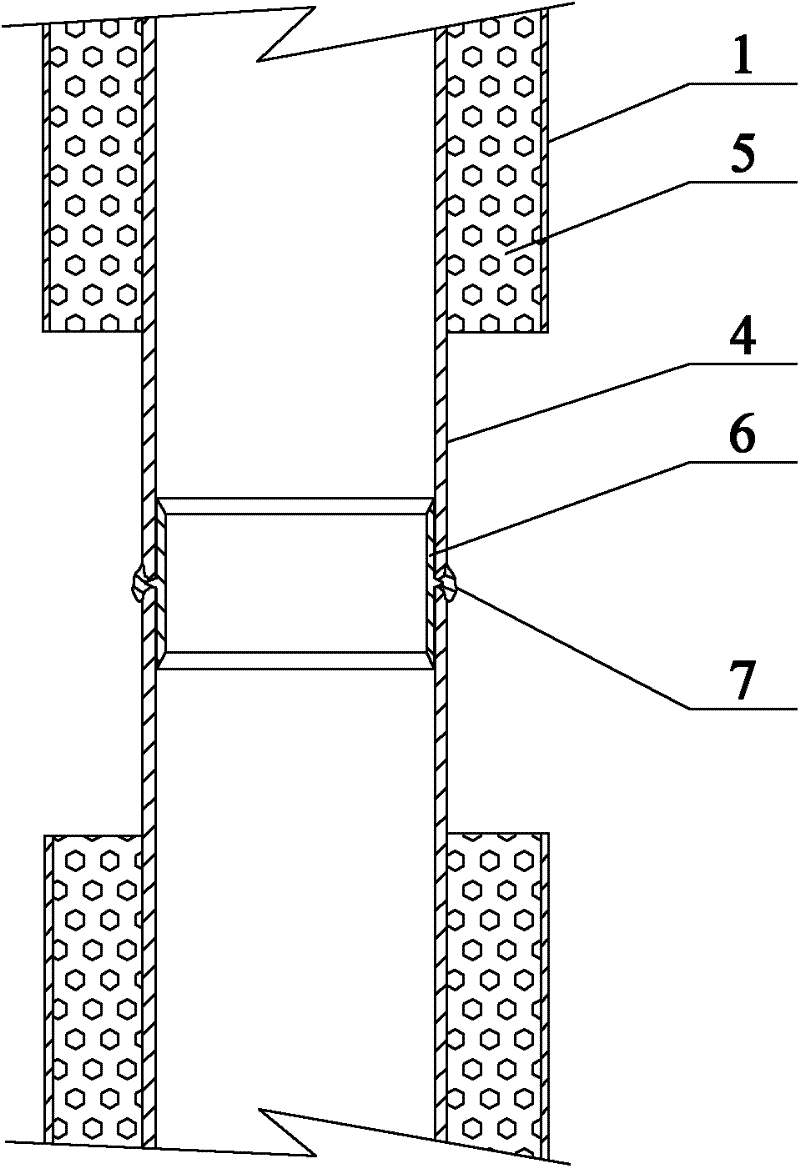

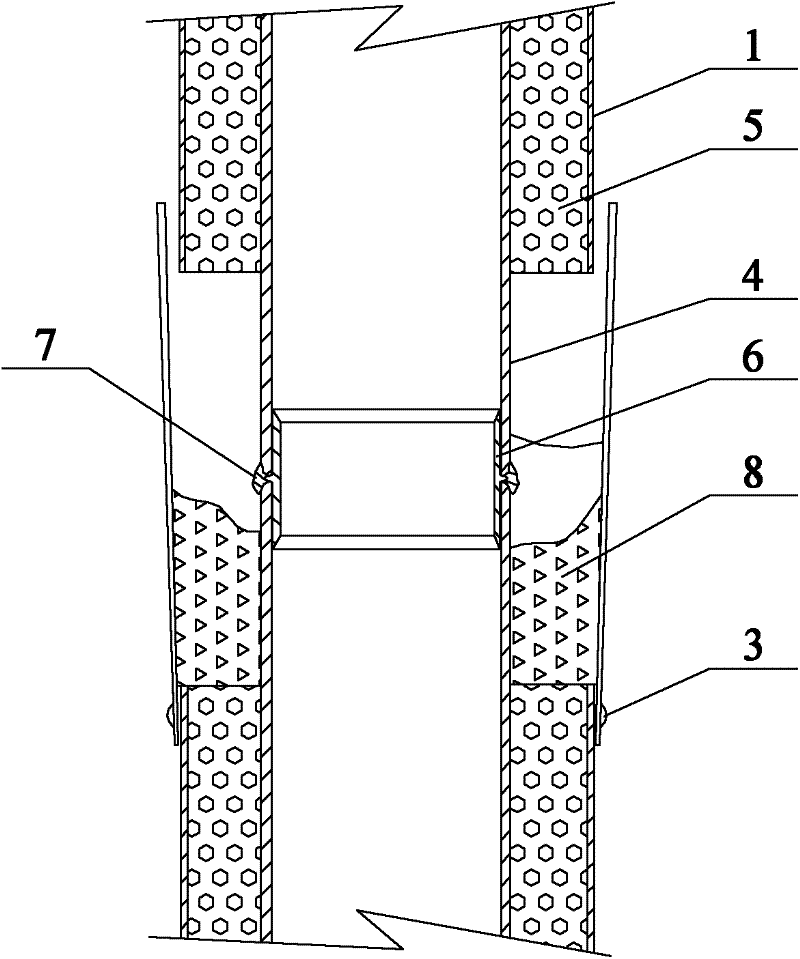

[0015] A kind of construction method that the specific embodiment of the present invention provides to reduce the effect of frost heaving on derrick foundation, (see Figure 1 ~ Figure 3 ) The process flow is: 1. Production of heat preservation pipes: use frozen pipes to make them. According to different pipe diameters, 5 to 9 pieces of cork are connected in series with iron wires, tied and fixed on the outer wall of the frozen pipes. The thickness of the corks is made according to the thickness of the polyurethane insulation layer. . The wooden blocks are evenly distributed, and it is advisable to evenly support the external hard polyethylene casing. Mix the white material and the black material according to the weight ratio of 1:1, stir and spray evenly into the space in the casing for foaming; 2. Freezing hole expansion: after the freezing drilling is completed, choose different diameters according to the outer wall diameter of the freezing pipe insulation layer Two-stage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com