Chlorine-free antifreezing agent for concrete as well as preparation method and application thereof

A technology for concrete and antifreeze, applied in the field of concrete admixtures, can solve the problems of corrosion of steel bars, poor compatibility, adverse effects on the durability of reinforced concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

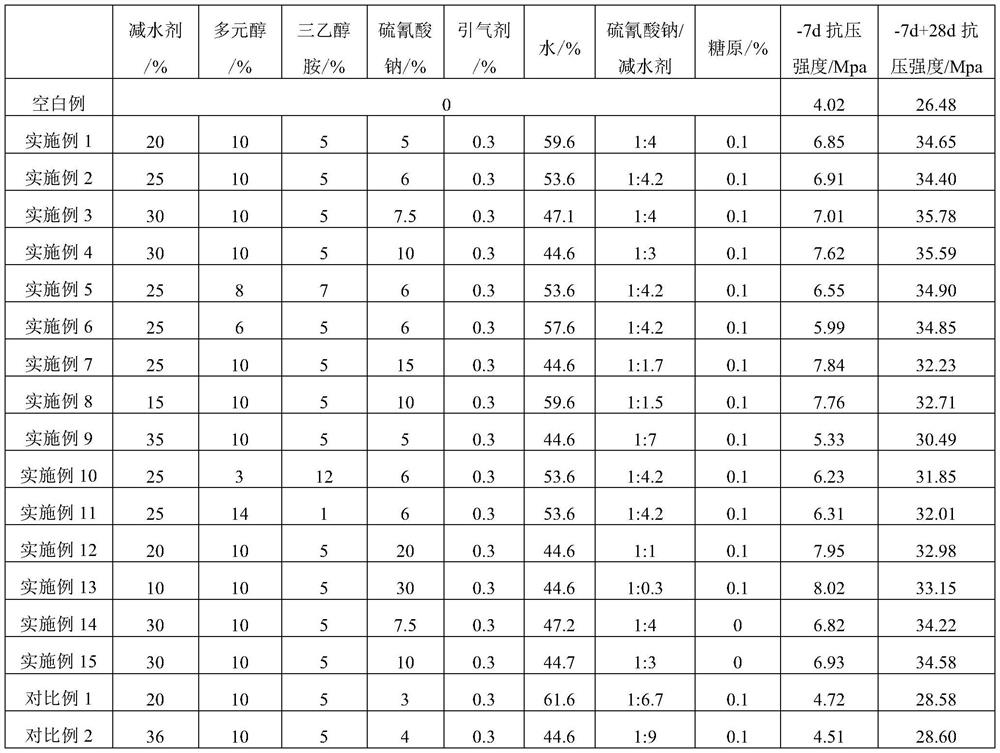

Examples

Embodiment 1

[0038] Weigh polycarboxylate superplasticizer (BLPC-1031 polycarboxylate superplasticizer, Hebi Baolai Chemical), polyol (ethylene glycol), triethanolamine, sodium thiocyanate, dodecane according to the ratio in Table 1 Sodium phenyl sulfonate, glycogen (molasses) and water are continuously stirred at room temperature until all of the above-mentioned substances are melted to obtain a chlorine-free concrete antifreeze.

Embodiment 2-15 and comparative example 1-2

[0040] The difference between Examples 2-15 and Comparative Examples 1-2 and Example 1 lies in the content of each component, see Table 1 for details.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com