Concrete anti-freezing agent and preparation method and application thereof

A technology of antifreeze and concrete, applied in the field of cement admixture, can solve the problems of low cement hydration rate, slow setting and hardening, low early strength, etc., and achieve the effects of reducing damage, accelerating cement hydration, and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

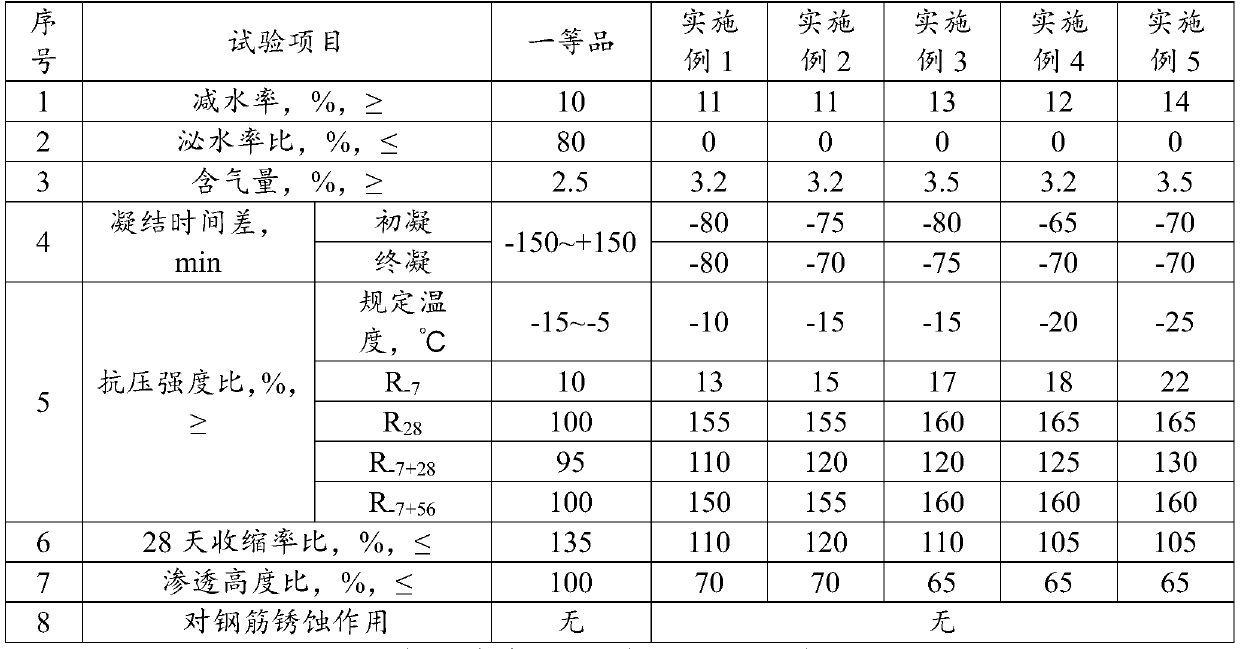

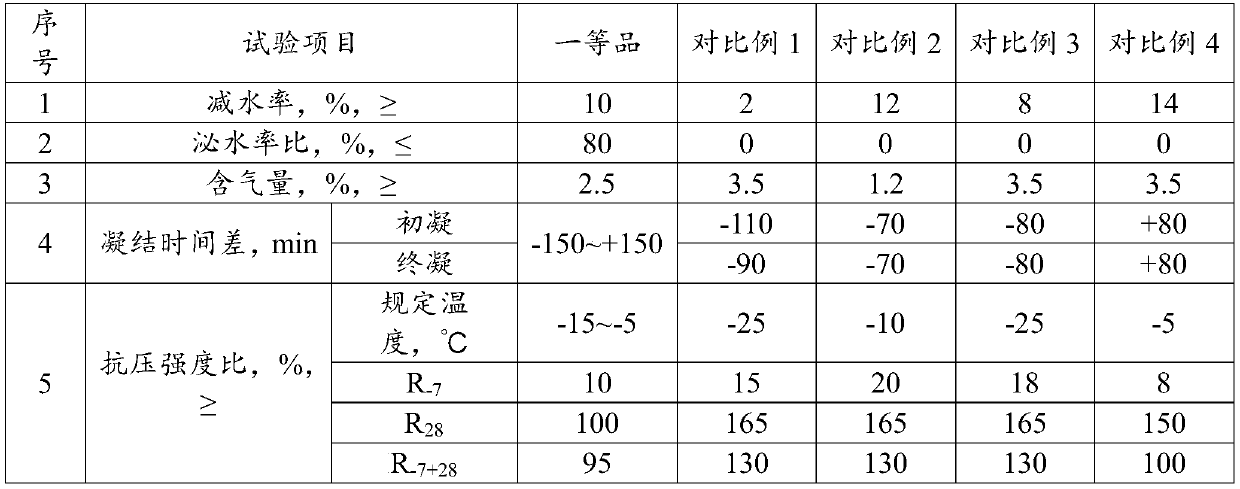

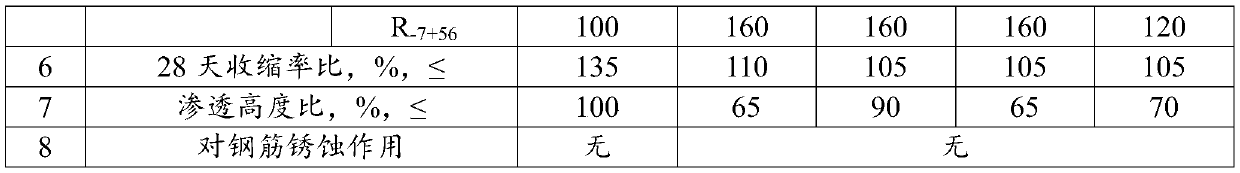

Examples

Embodiment 1

[0023] The preparation process of the concrete antifreeze in this embodiment is as follows:

[0024] 20 parts lignin, 5 parts H 2 O 2 , 5 parts of formaldehyde and 70 parts of water are put into the reaction kettle, raise the temperature of the reaction kettle to 75℃, stir evenly for 2h, then add NaOH solution to adjust the pH to 9, and slowly add 5 parts of Na 2 SO 3 , Stir uniformly and react for 4 hours to obtain the lignin sulfomethylation product, which is cooled to room temperature for later use;

[0025] 2. Weigh 20% of the above-mentioned lignin sulfomethylation product in mass percentage, glycerol 5%, triethanolamine 3%, calcium formate 2%, sodium citrate 1%, sodium dodecylbenzene sulfonate 0.2% , The balance is water, mix, continue to stir at room temperature for 2h until all of it melts, you can get concrete antifreeze.

Embodiment 2

[0027] The preparation process of the concrete antifreeze in this embodiment is as follows:

[0028] 20 parts lignin, 5 parts H 2 O 2 , 5 parts of formaldehyde and 65 parts of water are put into the reaction kettle, raise the temperature of the reaction kettle to 80℃, stir evenly for 2h, then add NaOH solution to adjust the pH to 10, slowly add 5 parts of Na 2 SO 3 , Stir uniformly and react for 4 hours to obtain the lignin sulfomethylation product, which is cooled to room temperature for later use;

[0029] Weigh 20% of the above-mentioned lignin sulfomethylation product by mass percentage, glycerol 7%, triethanolamine 4%, calcium formate 3%, sodium citrate 1%, sodium dodecylbenzene sulfonate 0.2%, and the rest The amount is water, mix, continue to stir at room temperature for 2 hours until all of it melts, you can get the concrete antifreeze.

Embodiment 3

[0031] The preparation process of the concrete antifreeze in this embodiment is as follows:

[0032] 30 parts of lignin, 7 parts of H 2 O 2 , 8 parts of formaldehyde and 60 parts of water are put into the reaction kettle, raise the temperature of the reaction kettle to 90℃, stir evenly for 2.5h, then add NaOH solution to adjust the pH to 11, slowly add 7 parts of Na 2 SO 3 , Stir uniformly and react for 5 hours to obtain the lignin sulfomethylation product, which is cooled to room temperature for later use;

[0033] Weigh 25% of the above-mentioned lignin sulfomethylation product by mass percentage, glycerol 6%, ethylene glycol 4%, triethanolamine 3%, sodium acetate 2%, sodium citrate 2%, dodecyl sulfonic acid Sodium is 0.3%, the balance is water, and the mixture is mixed. Stirring is continued at room temperature for 3 hours until all of it is melted to obtain concrete antifreeze.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com