Force transmission elements for fkv components

A technology of force components and composite components, applied in the field of force transmission components, can solve the problems of high mold costs and equipment costs, achieve good connection quality and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

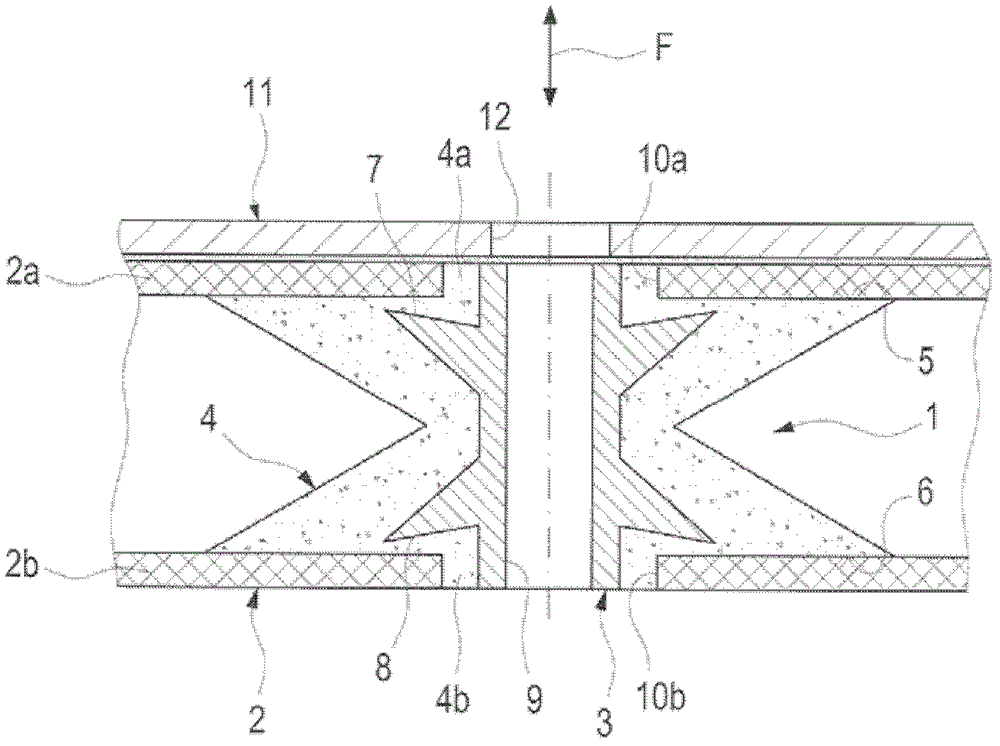

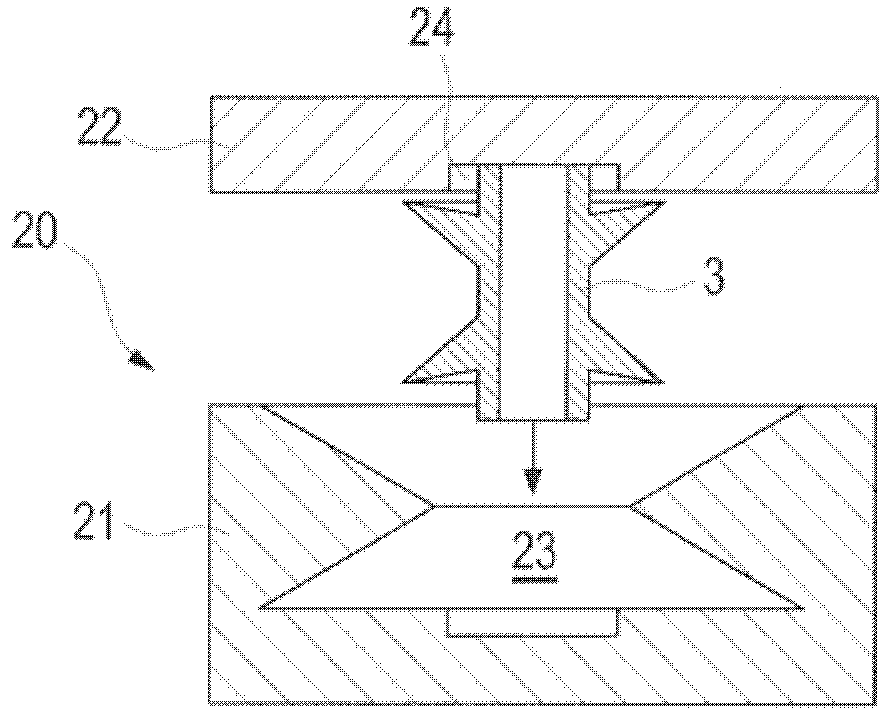

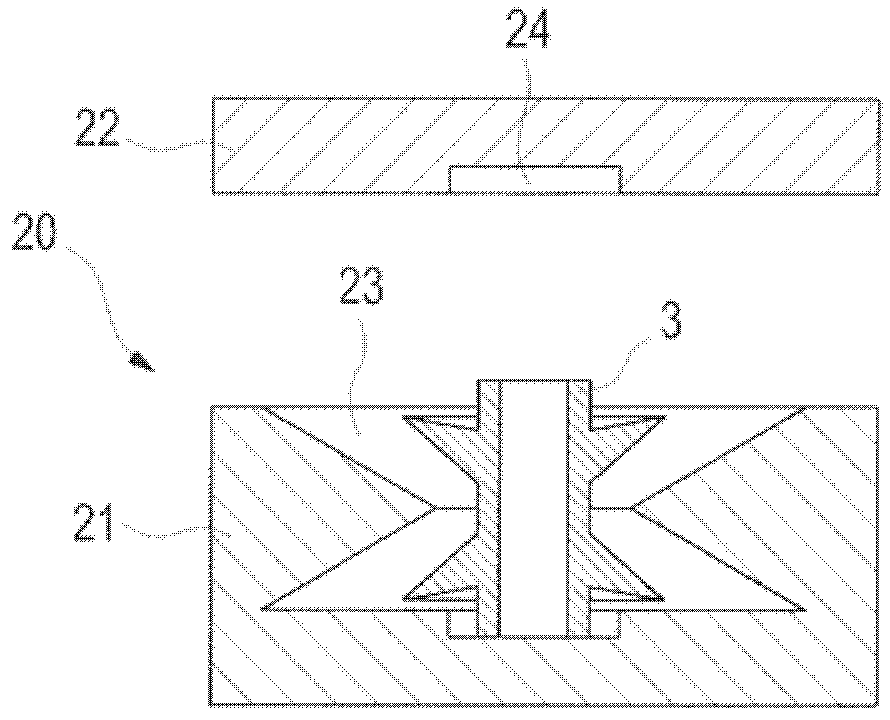

[0016] figure 1 The structural component 2 shown in FIG. 2 includes a first FKV component 2a and a second FKV component 2b, and the first and second FKV components are made of CFK, for example. The force transmission element 1 is used in the structural component 2 to realize a force transmission point.

[0017] The force transmission element 1 is designed as a hybrid component and includes a metal insert 3 made of steel, which is designed in a sleeve shape along the force transmission direction F when a through hole 9 is formed. The metal insert 3 is surrounded in a shell shape by a structure 4 composed of BMC material, the structure 4 having a substantially biconical cross section.

[0018] With the end side of the double cone shape, a contact surface 5 for abutting on the FKV component 2a and a contact surface 6 for abutting on the FKV component 2b are respectively formed. In addition, the contact surfaces 5 and 6 transition to flanges 4a and 4b, respectively, and the flanges 4a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com