Production process of a new high-performance nut

A production process and high-performance technology, applied in nuts, threaded fasteners, connecting components, etc., can solve the problems of increasing difficulty in locking copper nuts and mechanical parts, rising production costs of nuts, and structural strength not as good as steel, etc. To achieve the effect of quality and cost balance, low cost, and best performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

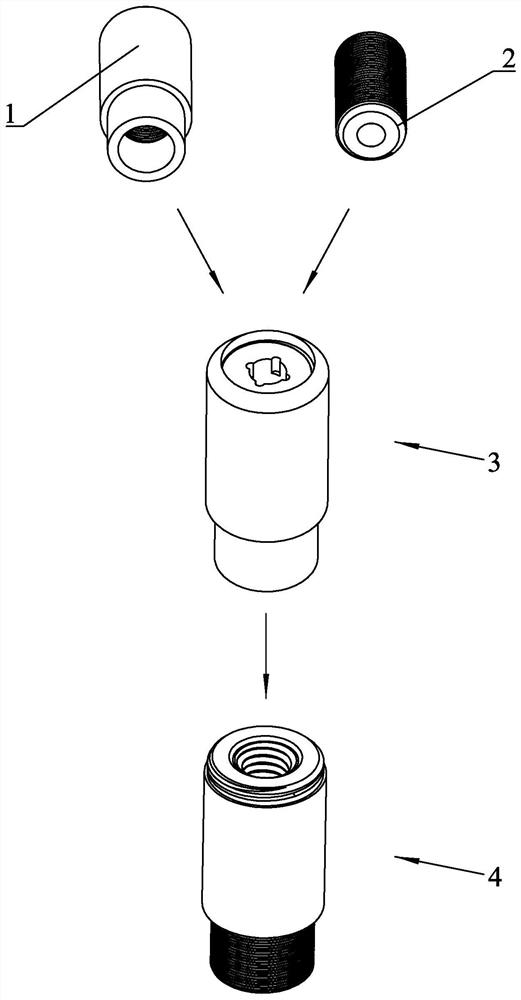

[0049] Such as Figure 1 to Figure 11 Shown, it is the production technique of a kind of high-performance novel nut that the present invention relates to, comprises the following steps:

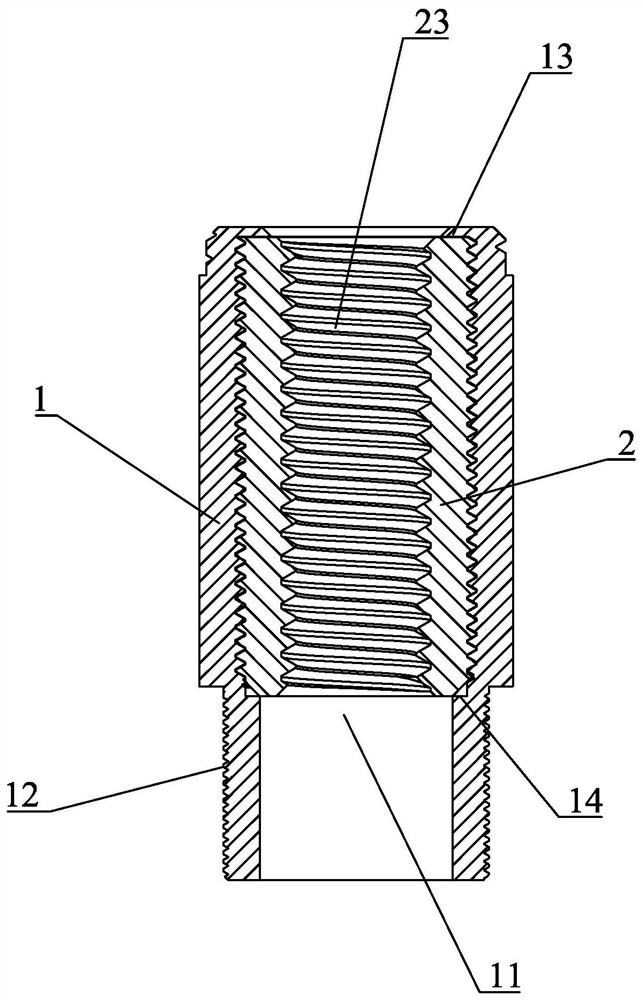

[0050] ① Prepare the outer shell 1 and the inlay 2, the outer shell 1 and the inlay 2 are made of different materials; the outer shell 1 is formed with a through hole 11; preferably, the outer shell 1 is made of steel The inlay body 2 is made of polymer plastic material or copper material.

[0051] ②The inlay body 2 is fixedly installed in the through hole 11 of the outer casing 1 to form a nut semi-finished product 3 .

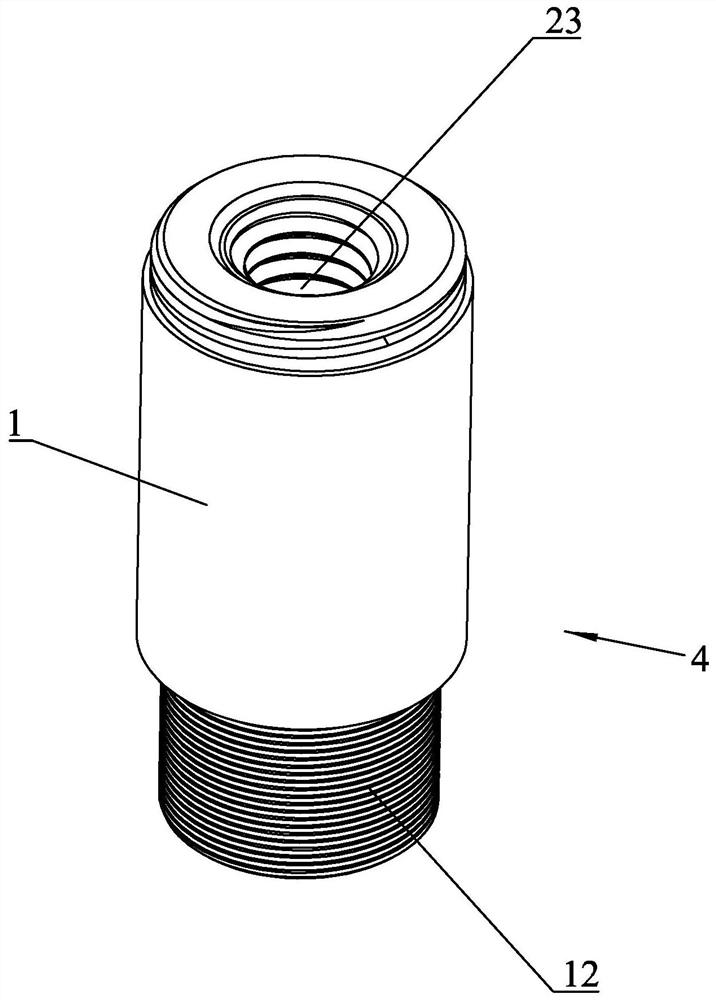

[0052] ③ Forming the screw hole 23 for cooperating with the screw rod in the inlay body 2 ; machining the outer shell 1 to form the finished nut 4 .

[0053] In this way, the production process of a new ty...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com