Dynamic weighing piezoelectric sensor for vehicle

A piezoelectric sensor and heavy-duty piezoelectric technology, applied in the field of sensors, can solve the problems of long cement curing time, low measurement efficiency, troublesome vehicle traffic, etc., and achieve long-term stability and reliability of weighing accuracy and good consistency of lateral eccentric load. , the effect of high weight measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

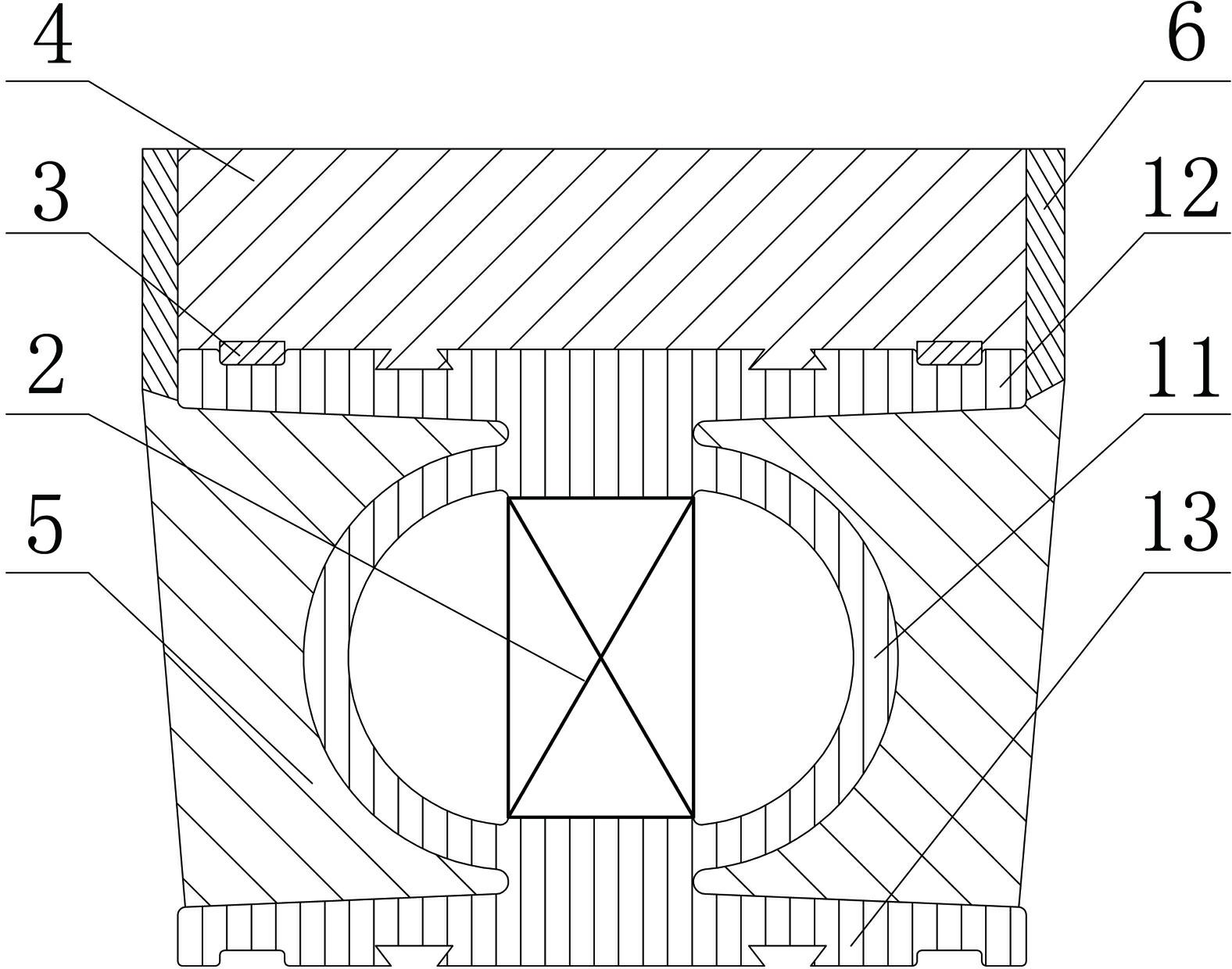

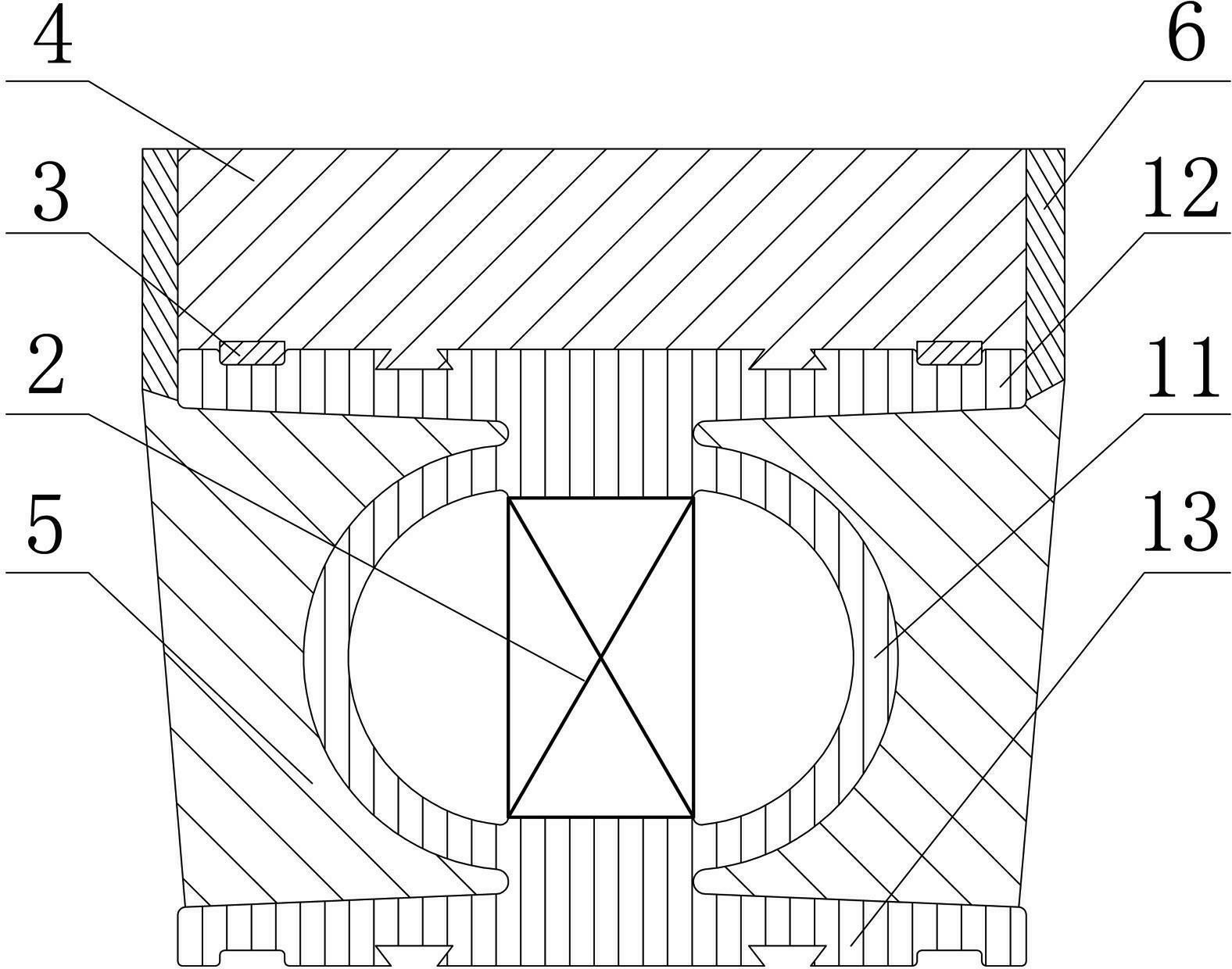

[0016] like figure 1 As shown, a vehicle dynamic weighing piezoelectric sensor, the sensor is in the shape of a strip as a whole, and it includes a strip-shaped road surface force layer 4, a strip-shaped weight-measuring force-bearing profile and a strip-shaped quartz pressure Electric sensor 2.

[0017] The weight-bearing profile includes a force-deformation cavity 11, a weight-bearing top plate 12, and a weight-measuring support base plate 13, wherein the weight-measuring force top plate 12 is arranged parallel to the weight-measuring support base plate 13, The force-deformation cavity 11 is arranged between the weight-measuring force-bearing top plate 12 and the weight-measuring support bottom plate 13, and the centers of the upper and lower outer surfaces of the force-deformation cavity 11 are respectively set on the weight-measuring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com