Micro force dynamic rotation measurement system and measurement and calibration method

A measurement system, dynamic rotation technology, applied in the direction of force/torque/work measuring instrument calibration/test, measurement of the balance force using force, measurement device, etc. effect and other problems, to achieve the effect of measuring span, eliminating resistance and simplifying movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

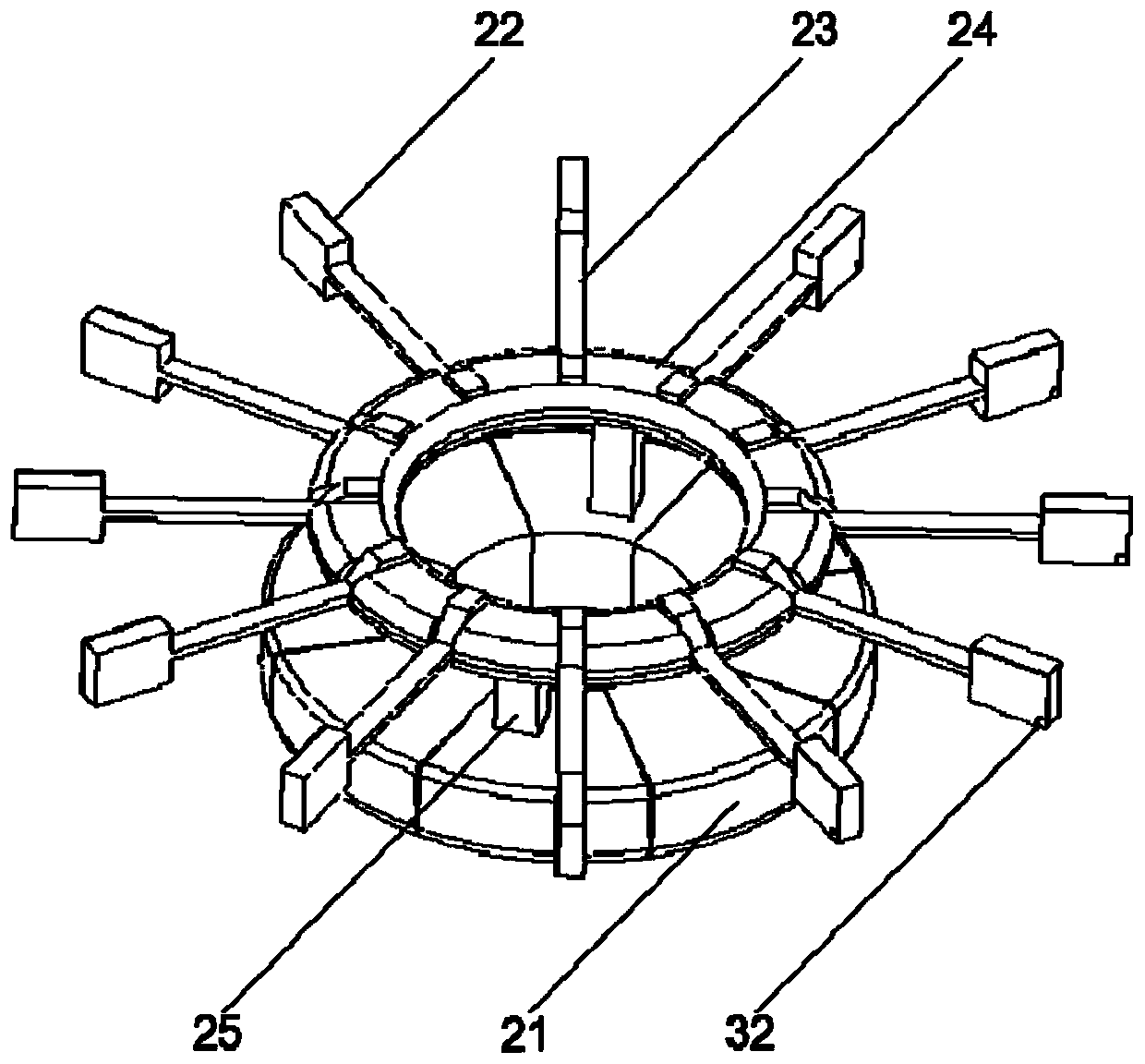

[0047] see figure 1 , figure 1 The structure of the micro force measurement and calibration system of the present invention is shown, wherein the structure of the micro force measurement and calibration system of the present invention, that is, the magnetic levitation rotor system, is composed of a ring-mounted superconducting guide rail (21) and a hard magnetic rotor, The hard magnetic rotor consists of a rotating shaft (24), a rotor support (23) and blades (22). The rotating shaft (24) is a flat cylindrical ring, adopts hard magnetic material, the inner diameter is 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thrust | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com