Rack structure of force standard machine

A frame structure, standard machine technology, applied in force/torque/power measuring instrument calibration/test, fluid pressure measurement, measuring device, etc., can solve the difficulty of locking the column, poor parallelism of the frame, locking High cost and other problems, to achieve the effect of low processing technology difficulty, low production cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

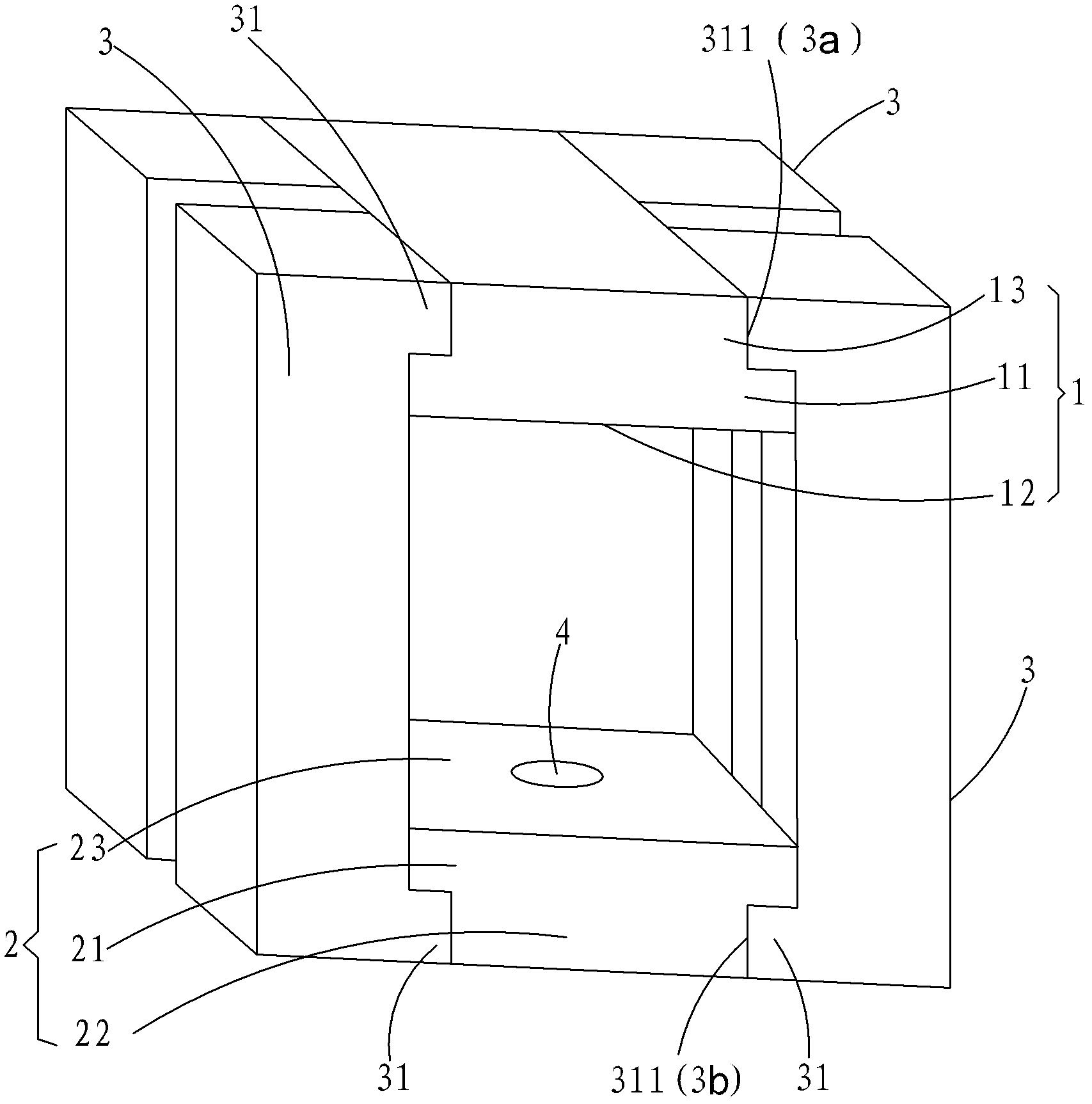

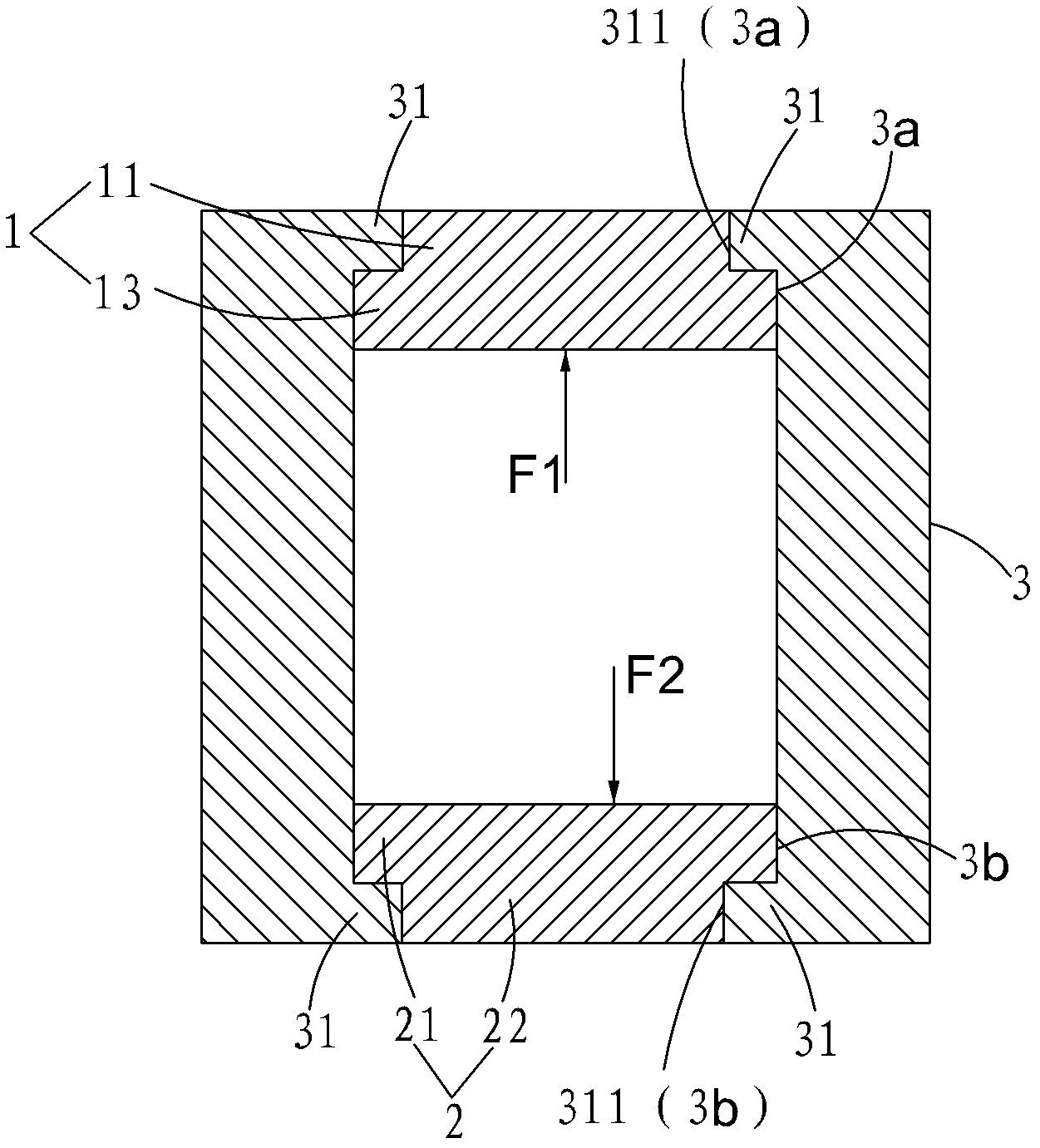

[0016] refer to Figure 1-2 As shown, a frame structure of a force standard machine includes an upper beam 1, a base 2, and two pairs of concave frames 3 arranged opposite to each other. The bottom surface 12 of the upper beam 1 and the upper surface 23 of the base 2 are respectively provided with a positioning hole 4 correspondingly. 4. Both are used for positioning with corresponding components. The upper beam 1 is in an inverted T-shaped structure, and the base is in a T-shaped structure.

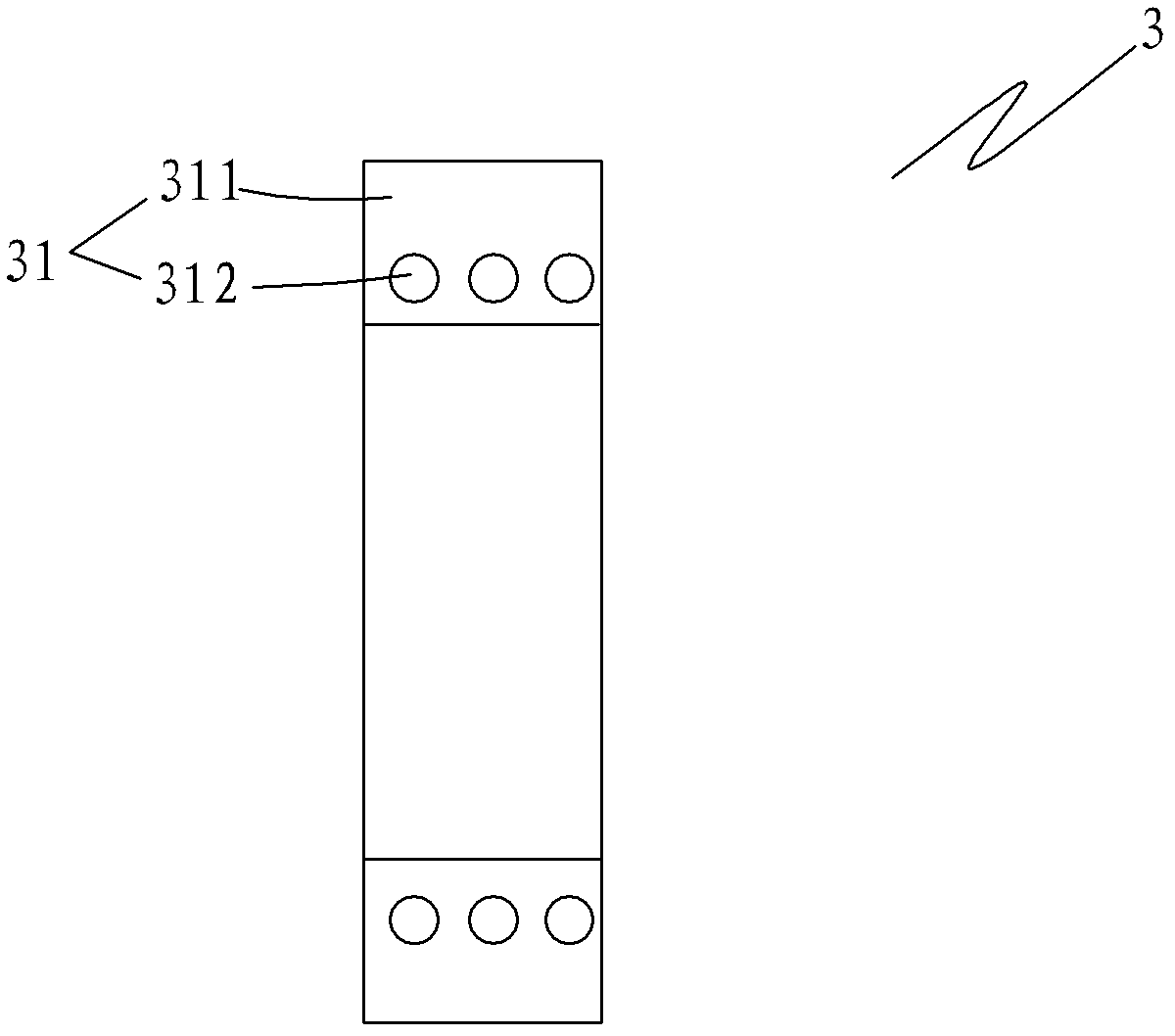

[0017] see again Figure 2-3 , each concave frame 3 contains two protrusions 31, one protrusion 31 of each concave frame 3 engages with the lateral edge 11 of the upper beam 1, and the other protrusion 31 of the concave frame 3 Engage with the lateral edge 21 of the base 2, and the lateral edge 11 of the upper beam 1 and the lateral edge 21 of the base 2 are all attached to the inner edge of the concave frame 3, and the upper beam 1 The side edge of the vertical side 13 and the side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com