Sample suction nozzle device for viscometer

A viscometer, an integrated technology, applied in measuring devices, flow characteristics, instruments, etc., can solve the problems of fragile glass, broken glass, scrapped straight tube viscometers, etc., to achieve the effect of convenient experiment and field work, and improved sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

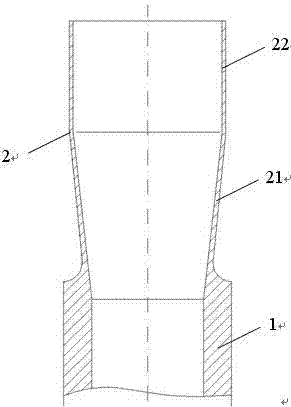

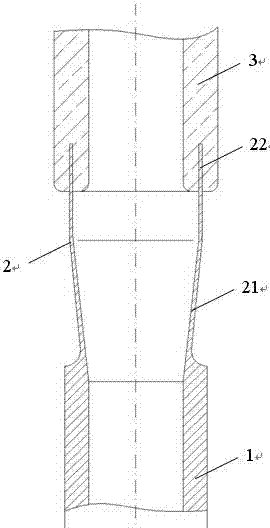

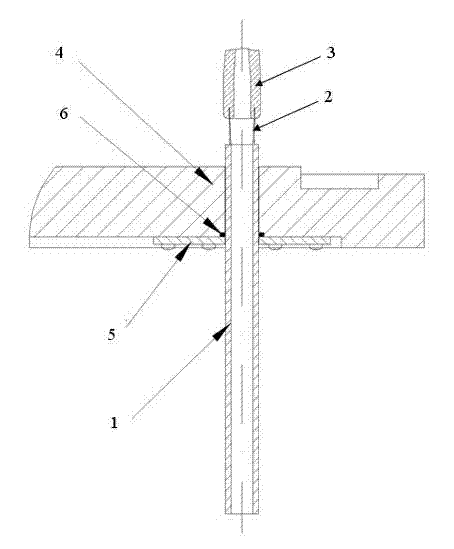

[0019] The following combination Figure 1 ~ Figure 3 , a preferred embodiment of the present invention is described in detail.

[0020] The suction nozzle device of the viscometer of the present invention is made of metal material, and it is integrated with one end of the straight tube viscometer made of glass by welding, and the metal suction nozzle device is tightly installed in the constant temperature bath base to complete the fixation of the straight tube viscometer.

[0021] The metal suction nozzle device is made of copper material, and the copper content in the copper material is greater than 99.7%, so the total impurity content is less than 0.3%. Further, the impurities in the copper material include oxygen, phosphorus and arsenic, because the content of these impurities will affect the performance of copper, which will cause the suction nozzle device to fail to weld during the welding process with the glass viscometer , or the color is yellowish during welding, in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com