Automatic board shape deviation correction cooperative control method for artificial board continuous flat pressing

A collaborative control, automatic board technology, applied in the field of mechanical equipment control, can solve problems such as uneven board thickness, material and energy loss, and achieve the effect of product shape assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

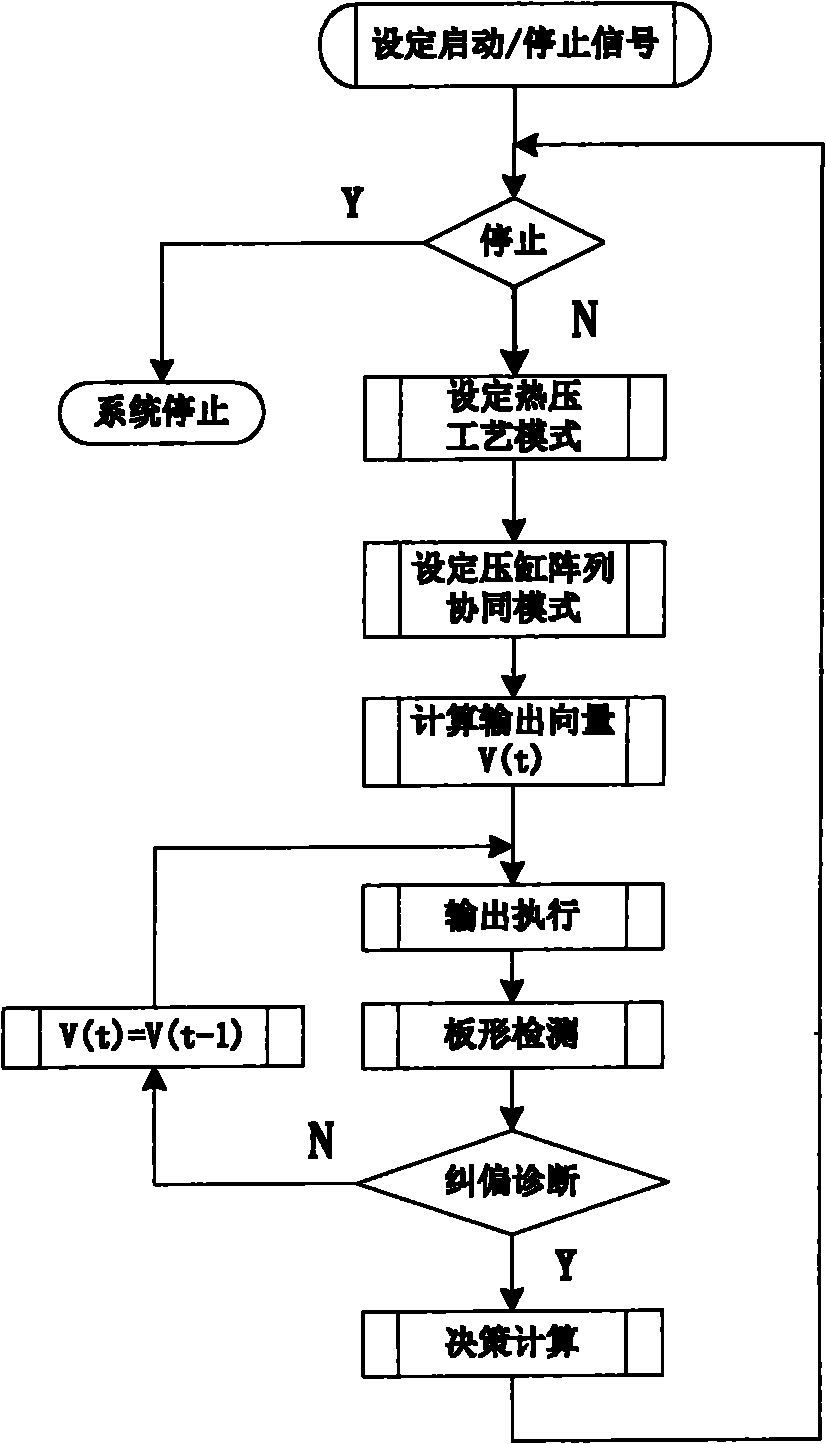

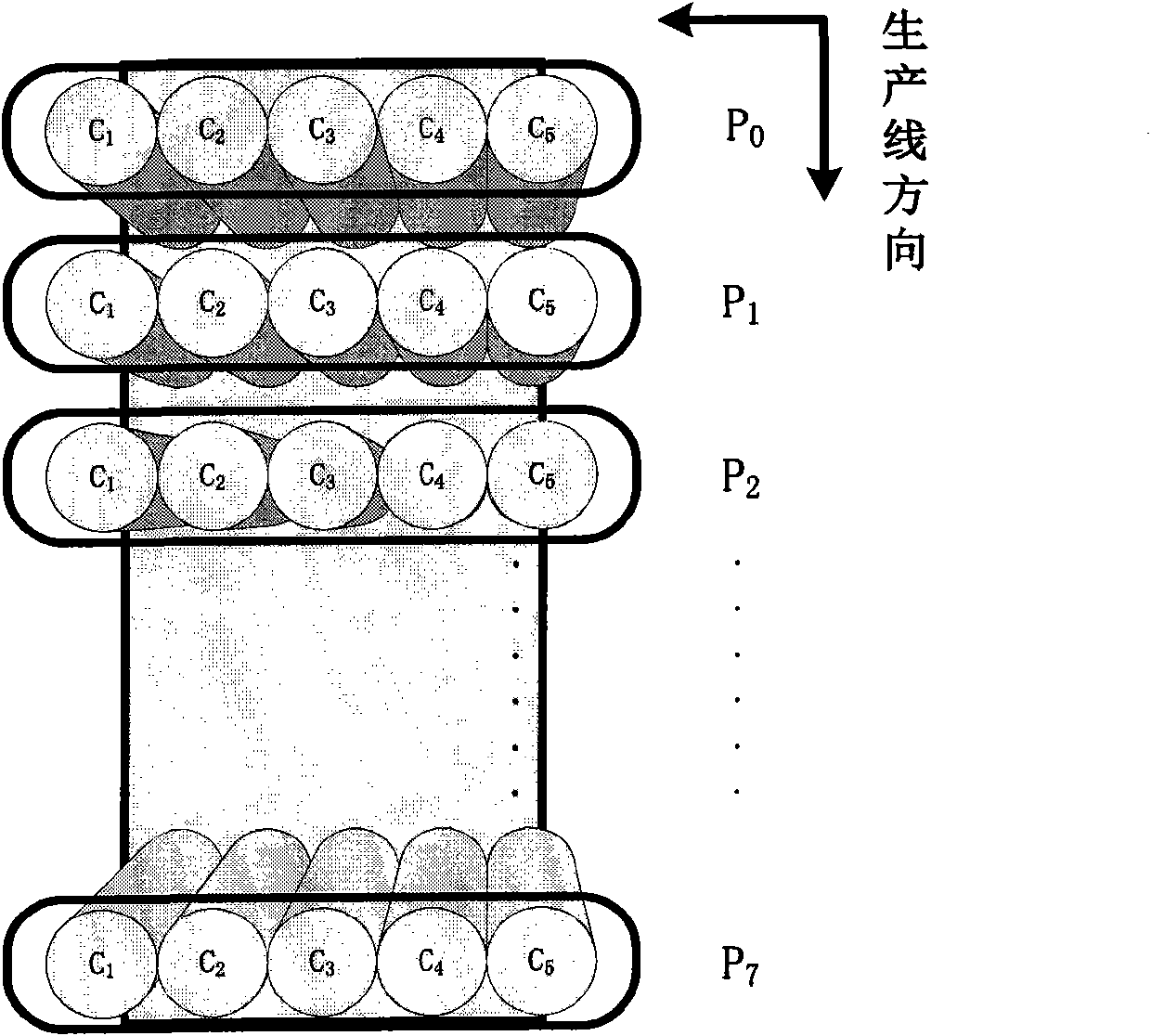

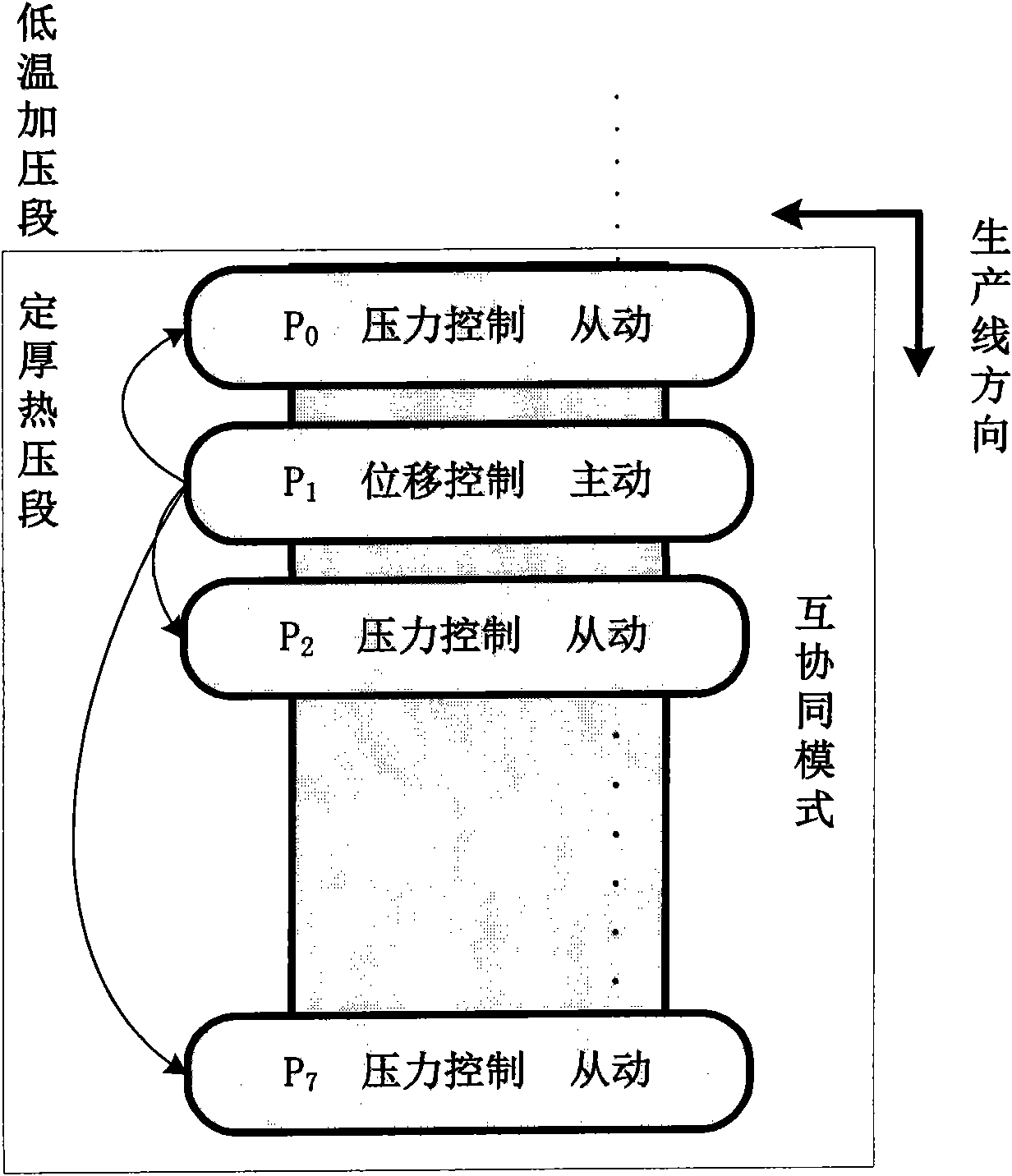

[0025] In this embodiment, the frame P above the hot-pressing plate of the fixed-thickness hot-pressing section 0 ,P 1 ,P 2 ,...,P 7 Arranged in sequence along the direction of the production line, each rack contains a hydraulic cylinder C 1 、C 2 ,...,C 5 .

[0026] After the pre-pressed slab is pressurized at low temperature, it enters the pressurized thickness section, which is controlled by the frame P 1 Set thickness; Rack P required 1 Working in displacement mode, frame P 0 ,P 2 ,...,P 7 Work in the pressure mode; at this time, the production line works in the mutual cooperation mode, and the rack P 1 The active action, the rest of the racks are slave actions, such as image 3 ; at rack P 1 , requires C 2 、C 3 、C 4 Working together in displacement (or pressure) mode, C 1 、C 5 Working in the pressure mode, the rack P at this time 1 Working in self-coordinated mode, C 2 、C 3 、C 4 is an active action, C 1 、C 5 is a driven action, such as Figure 4 ; I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com