Clamping device, motor, and disk drive device

A technology of clamping device and motor, which is applied in the field of motor, disk drive device and clamping device, and can solve the problem of setting the platform and claw separately with high position accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

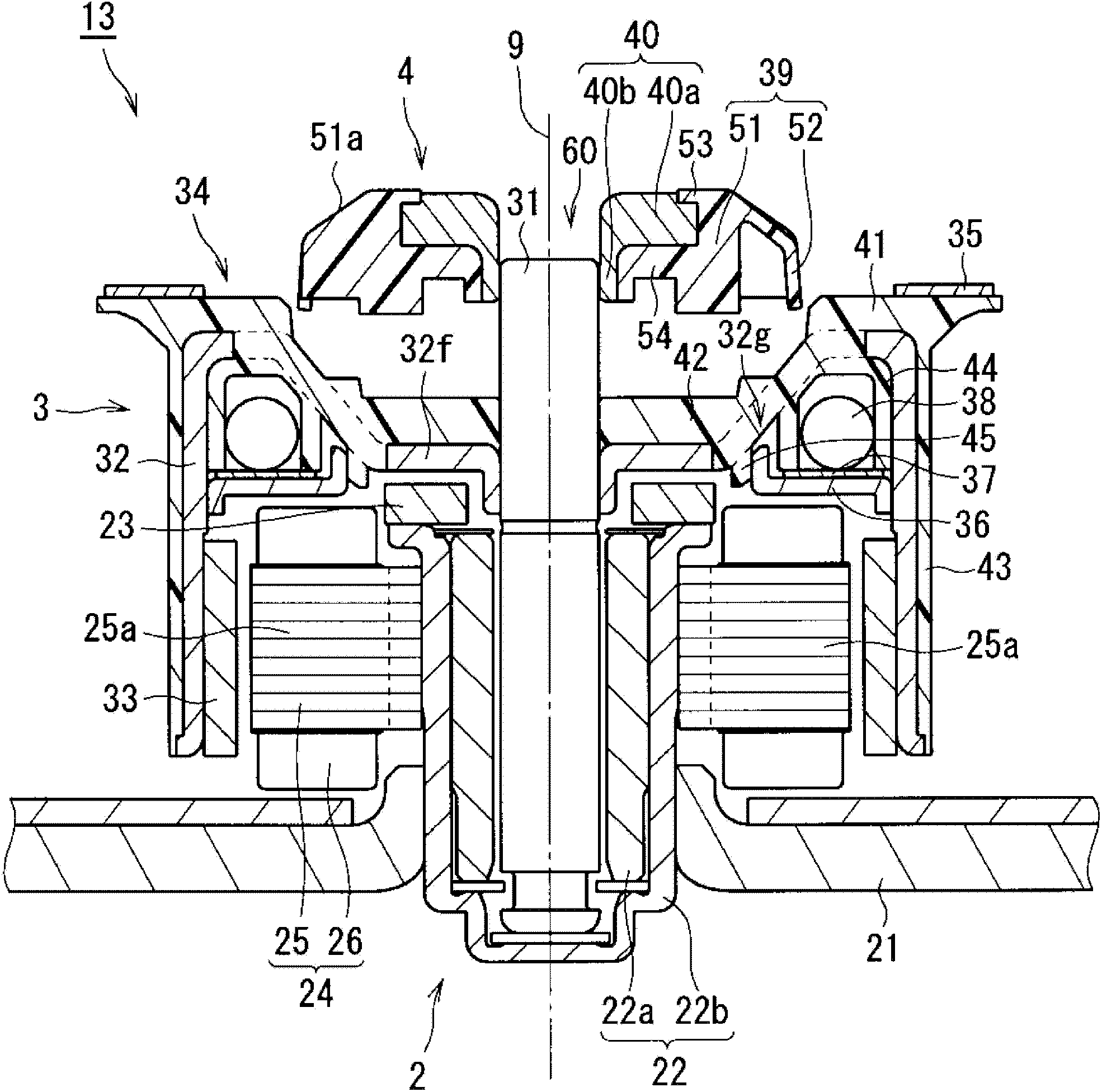

[0058] Hereinafter, exemplary embodiments of the present invention will be described with reference to the drawings. In addition, in the following description, the direction along the central axis of the clamp device is defined as the up-down direction, and the aligning portion side is defined as the upper side with respect to the rotor holder, and the shape and positional relationship of each member will be described. However, this only defines the up and down directions for the convenience of describing the present invention, and does not limit the postures of the motor and the disk drive device of the present invention during use.

[0059] 1. Clamping device according to one embodiment

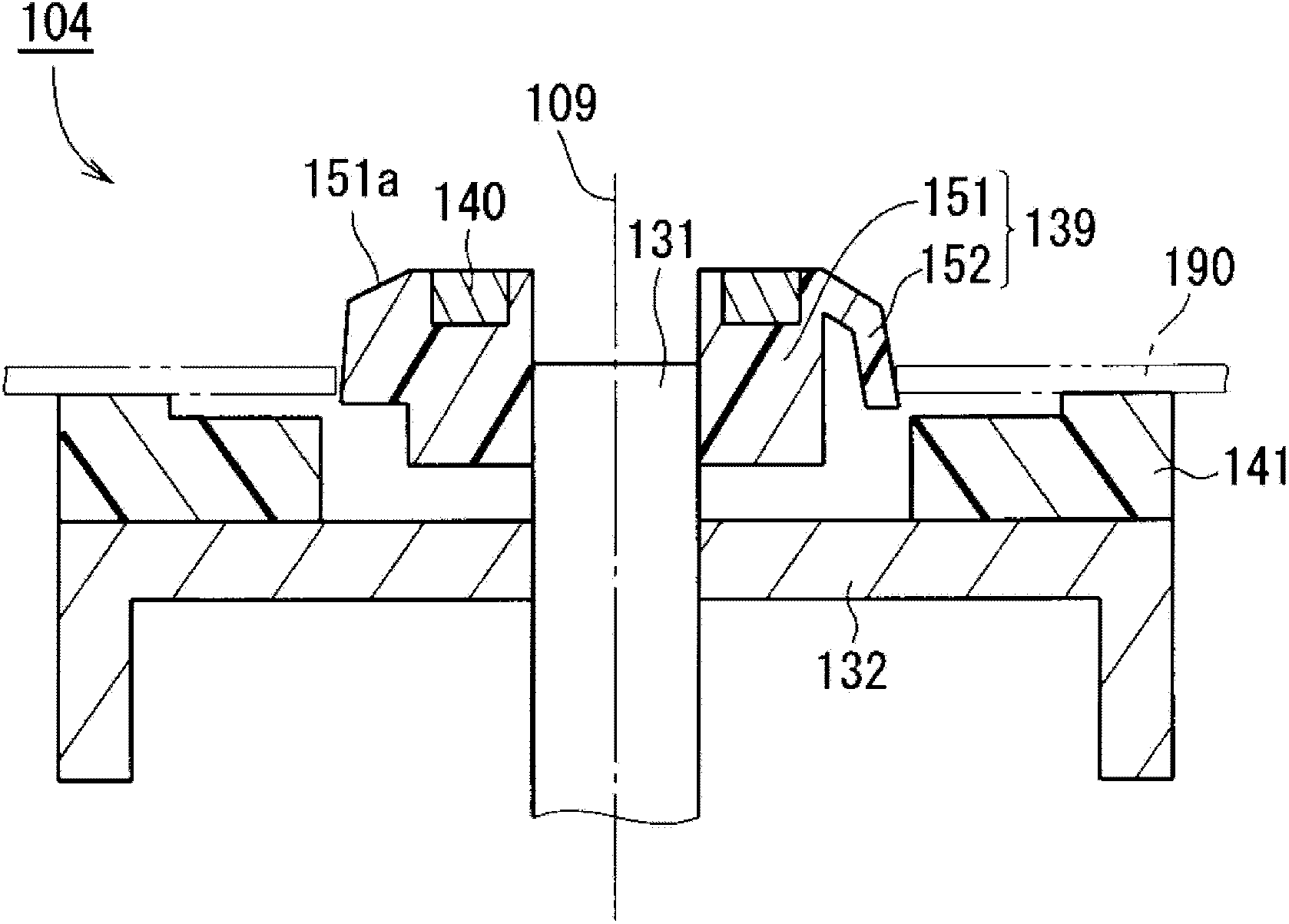

[0060] figure 1 It is a vertical cross-sectional view of the clamp device 104 according to one embodiment of the present invention. Such as figure 1 As shown, the clamping device 104 includes a shaft 131 , a rotor holder 132 , a disc loading portion 141 , an aligning portion 139 and a co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com