Method, device and system for processing circuit board

A technology of circuit board and circuit layer, which is applied in the direction of printed circuit, printed circuit manufacturing, and electrical connection formation of printed components, etc., which can solve problems such as difficult to determine the position of the alignment target, unrecognizable alignment target, poor alignment accuracy, etc. , to achieve the effect of enhancing the CCD system to identify the alignment target

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

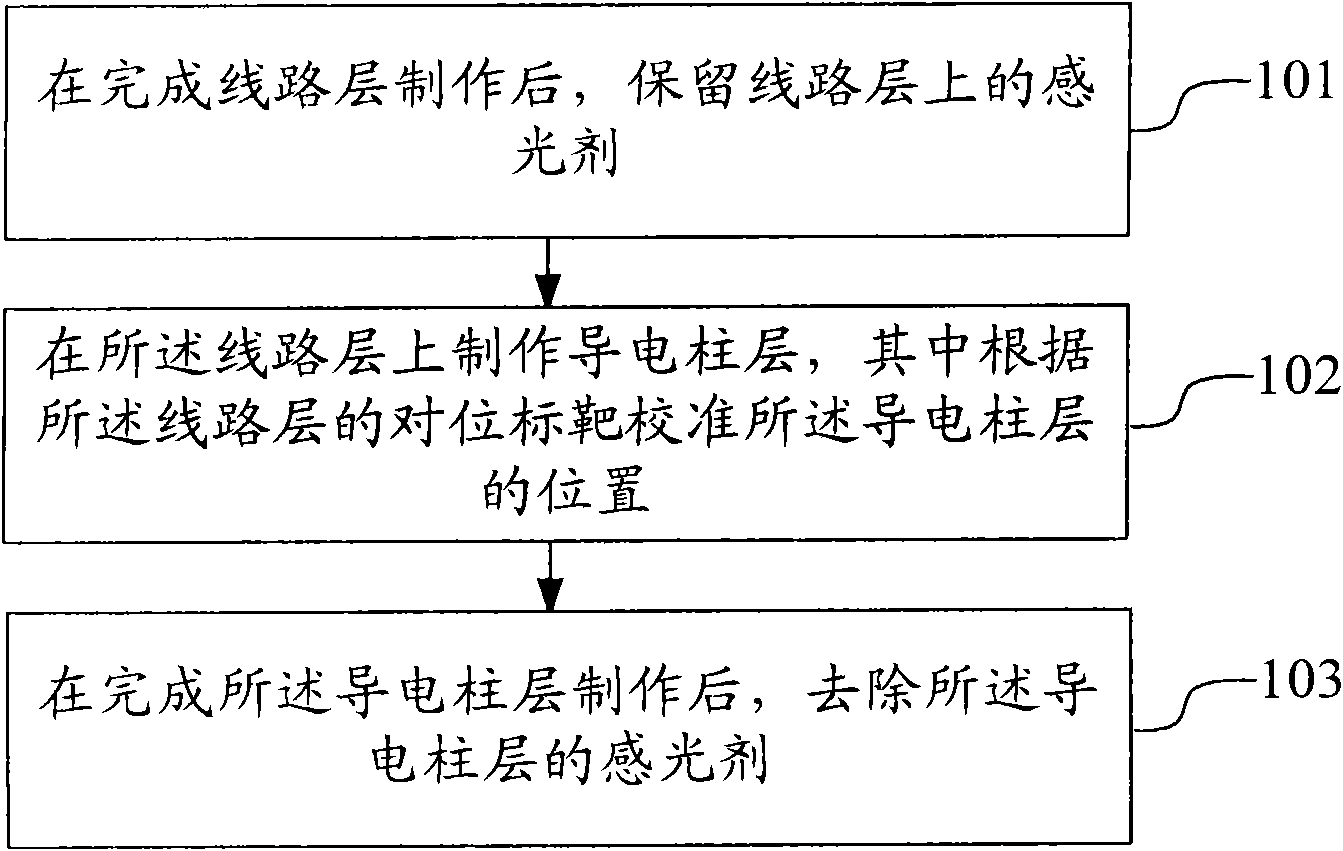

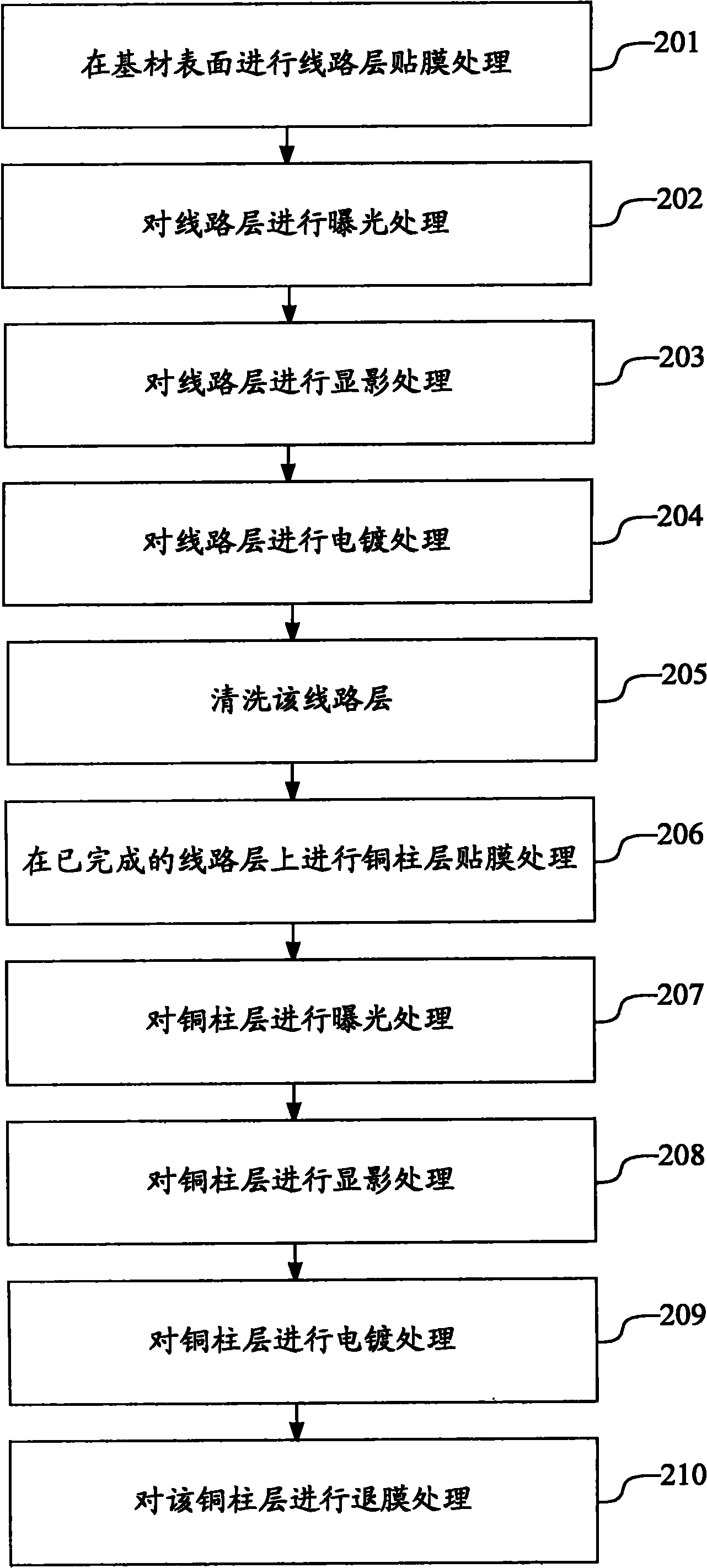

[0028] The invention provides a method for processing circuit boards, characterized in that the method comprises:

[0029] After completing the production of the circuit layer, keep the photosensitive agent on the circuit layer;

[0030] making a conductive column layer on the circuit layer, wherein the position of the conductive column layer is calibrated according to the alignment target of the circuit layer;

[0031] After the fabrication of the conductive column layer is completed, the photosensitive agent of the conductive column layer is removed.

[0032] Preferably, in each embodiment of the present invention, after the circuit layer is fabricated, the circuit layer is cleaned, preferably with an acidic solution.

[0033] Preferably, in each embodiment of the present invention, the alignment target is determined when manufacturing the circuit layer.

[0034] Preferably, in each embodiment of the present invention, when making the circuit layer or the conductive column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com