Pressure fuselage of an aircraft with aft-side pressure bulkhead

A pressure chamber and fuselage technology, applied in the direction of fuselage bulkhead, fuselage, aircraft parts, etc., can solve the problem of troublesome removal of debris, reduce work cost and ensure static stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

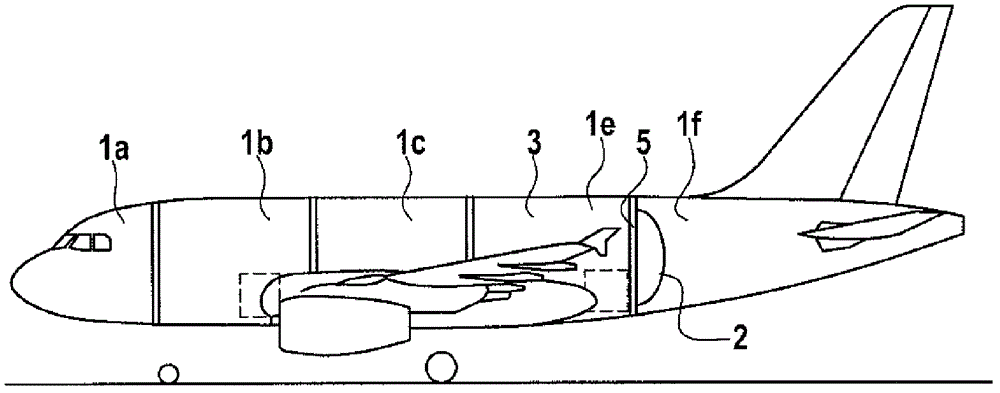

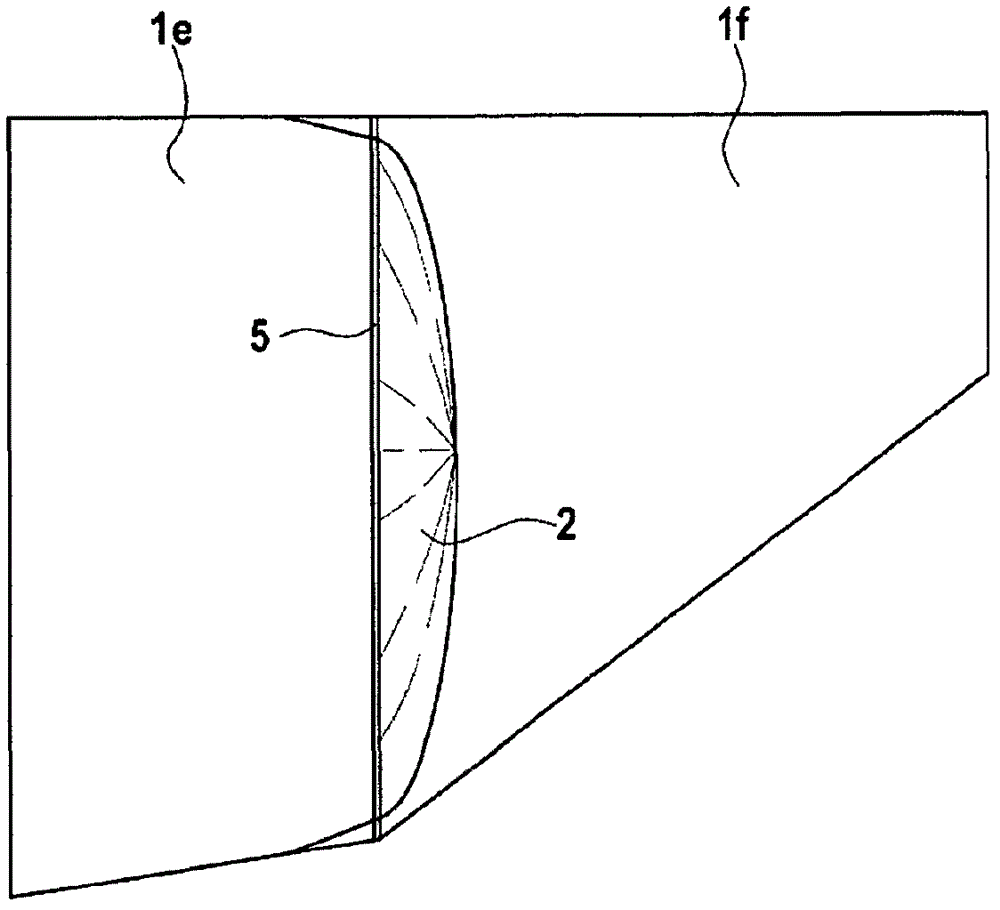

[0028] according to figure 1 , viewed in the longitudinal direction, the pressure fuselage of the aircraft consists of a plurality of fuselage sections 1a-1e, which are connected to each other at the borders by closed elliptical annular cross-sections in order to produce a long-shaped pressure fuselage. Between the fuselage section 1f forming the tail area and the adjacent fuselage section 1e, the tail-side pressure bulkhead 2 is fixed by means of a special bulkhead profile 5, said pressure bulkhead enclosing the pressure area inside the aircraft. 3 Separate from the unpressurized tail region, the pressure bulkhead is assigned to the fuselage section 1f. In the pressurized area 3 inside the aircraft there is a passenger cabin as well as a cargo space arranged below the passenger cabin.

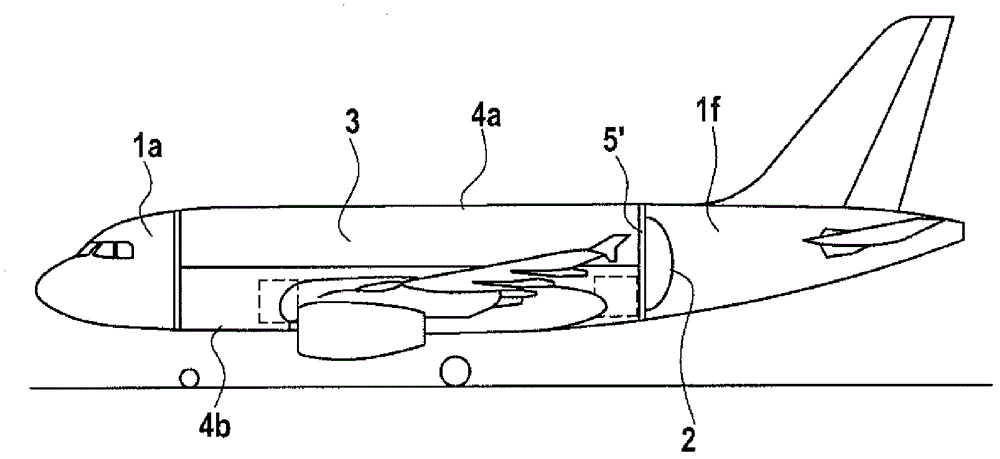

[0029] In contrast, figure 2 A pressure nacelle constructed according to the so-called shell division concept is shown schematically. In addition to the traditional fuselage section 1 a fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com