Frame width adjusting mechanism

A technology of width adjustment and racking, which is applied in the field of slideways and slide rails, and can solve problems such as failure to install, poor operation of the drawer device 7, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings and the embodiments.

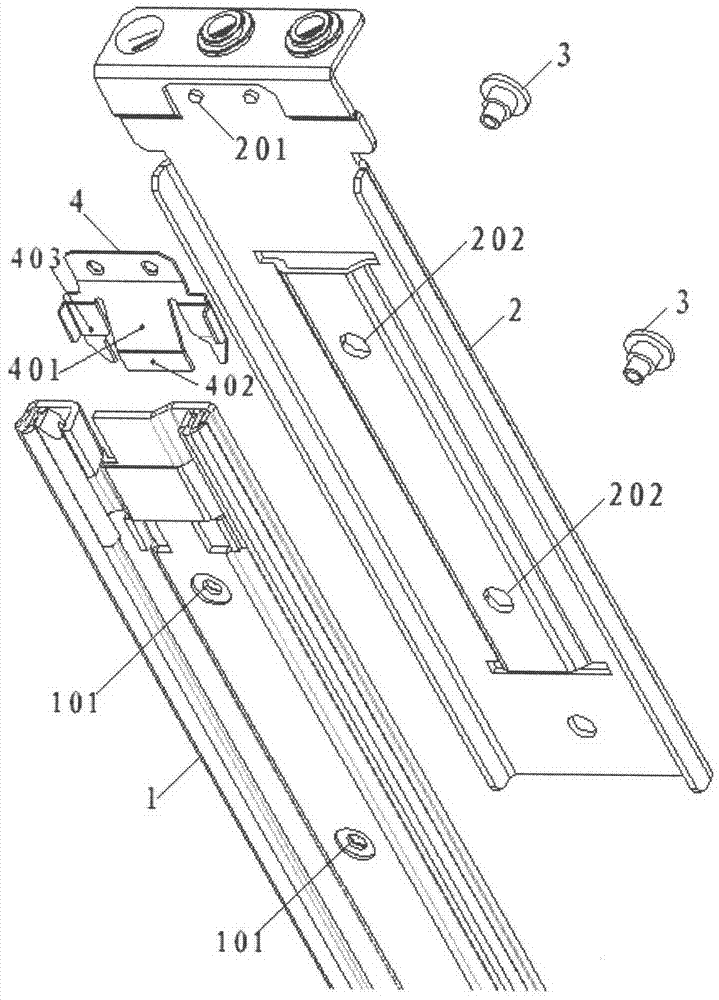

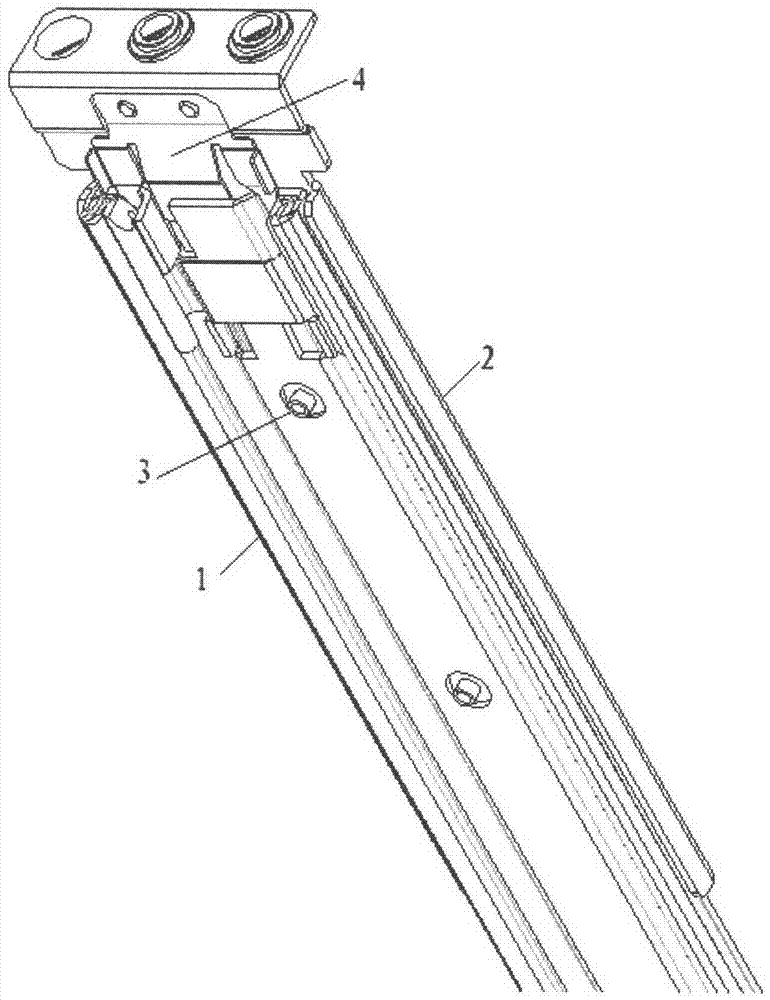

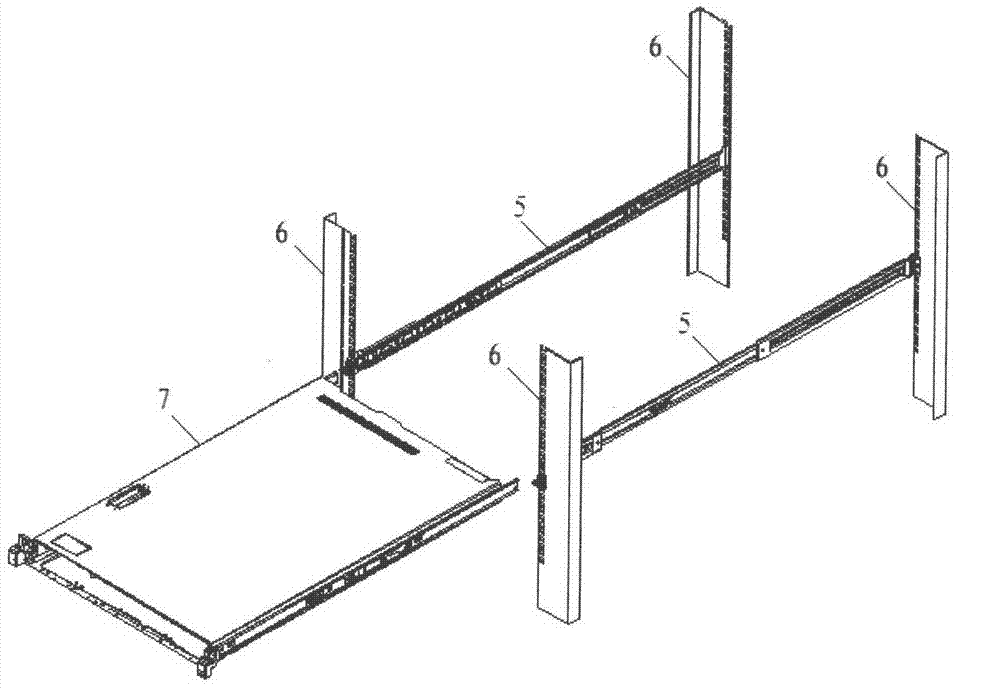

[0022] See figure 1 , figure 2 As shown, a rack width adjustment mechanism includes a slide rail outer frame 1 and a front bracket 2. The front bracket 2 is provided with a pair of through holes 202, and the slide rail outer frame 1 is provided with a pair of rivets for fixing Holes 101, the pair of through holes 202 and the pair of rivet fixing holes 101 are mutually matched, and are sequentially penetrated by a pair of step rivets 3, thereby fixing the front bracket 2 to the outer frame of the slide rail 1, one end of the front bracket 2 is provided with a pair of convex hulls 201, the pair of convex hulls 201 is fixed with an elastic sheet mechanism 4, the elastic sheet mechanism 4 includes an elastic bending surface 401, the elastic bending The two sides of the curved surface 401 are respectively the transition joint surface 403; one end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com