Novel feeding bottle with automatic milk spilling function

A feeding bottle and milk spilling technology, which is applied to feeding bottles and other directions, can solve the problems of large suction, complex structure, unfavorable promotion and application of baby feeding bottles, etc., and achieve the effect of reducing oxidized liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

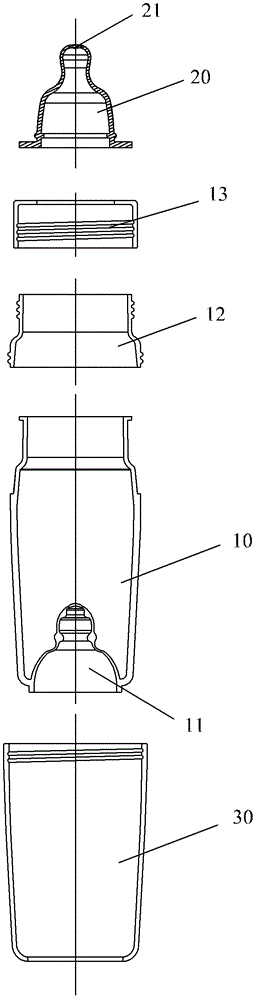

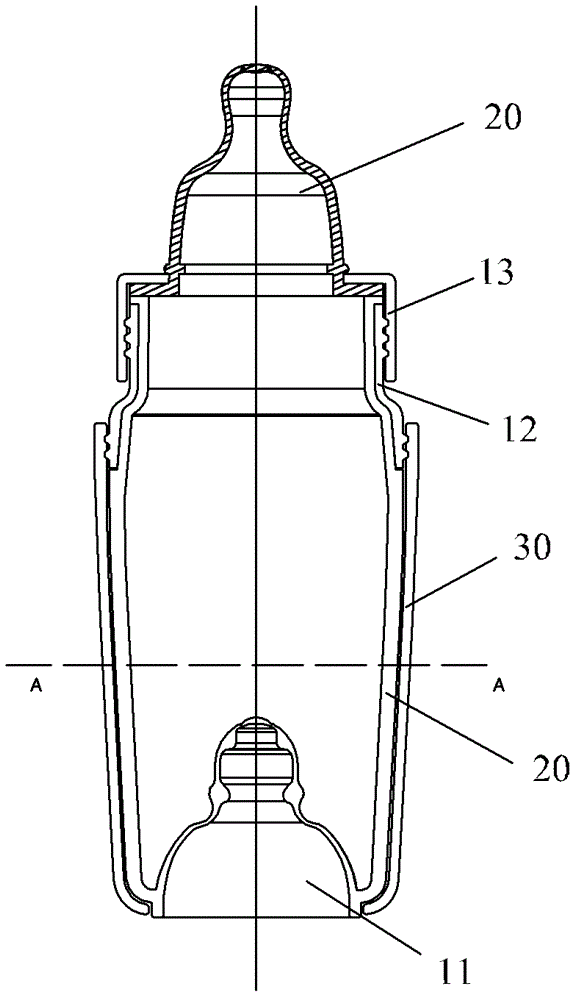

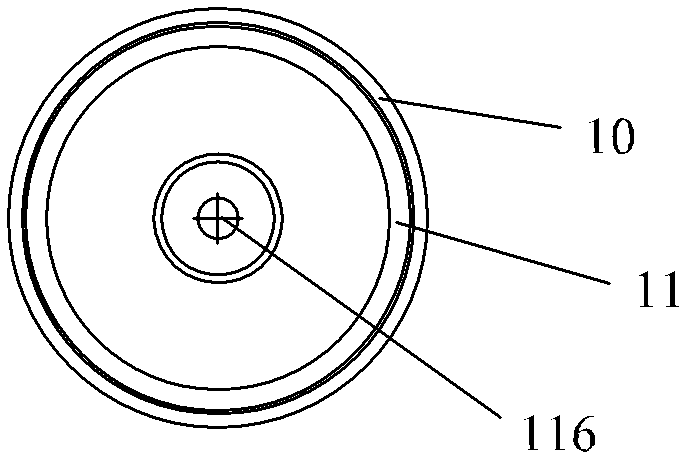

[0030] see figure 1 and 2 As shown, the new feeding bottle with automatic milk overflow function of the present invention mainly includes: a feeding bottle body 10, a bottom protrusion 11 formed by indenting the bottom of the bottle into the bottle body 10, a nipple 20, a bottle body protective cover 30, etc. . The port overcoat of the bottle body 10 is connected with a bottle mouth fixing sleeve 12, and the material of the bottle mouth fixing sleeve 12 can be plastic or other hard materials that can play a role in fixing. The bottle mouth fixing sleeve 12 can be threadedly connected with the feeding bottle cap 13 sleeved on its outer surface. The bottom silica gel of the pacifier 20 can be embedded in the feeding bottle cap 13 . A filter screen (not shown) can also be installed in the port of the bottle body 10 for filtering larger viscosity or solid matter in the feeding bottle liquid.

[0031] The feeding bottle body 10 is made of hard plastic material or food-grade sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com