Oxygen generating device special for ozone device

An oxygen generation and ozone machine technology, which is applied in the field of special oxygen generation devices for ozone machines, can solve the problems of waste of regenerated oxygen, increase system operating costs, and the water content of oxygen does not meet the requirements of the use of ozone machines, and achieve the effect of ensuring emptying and waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

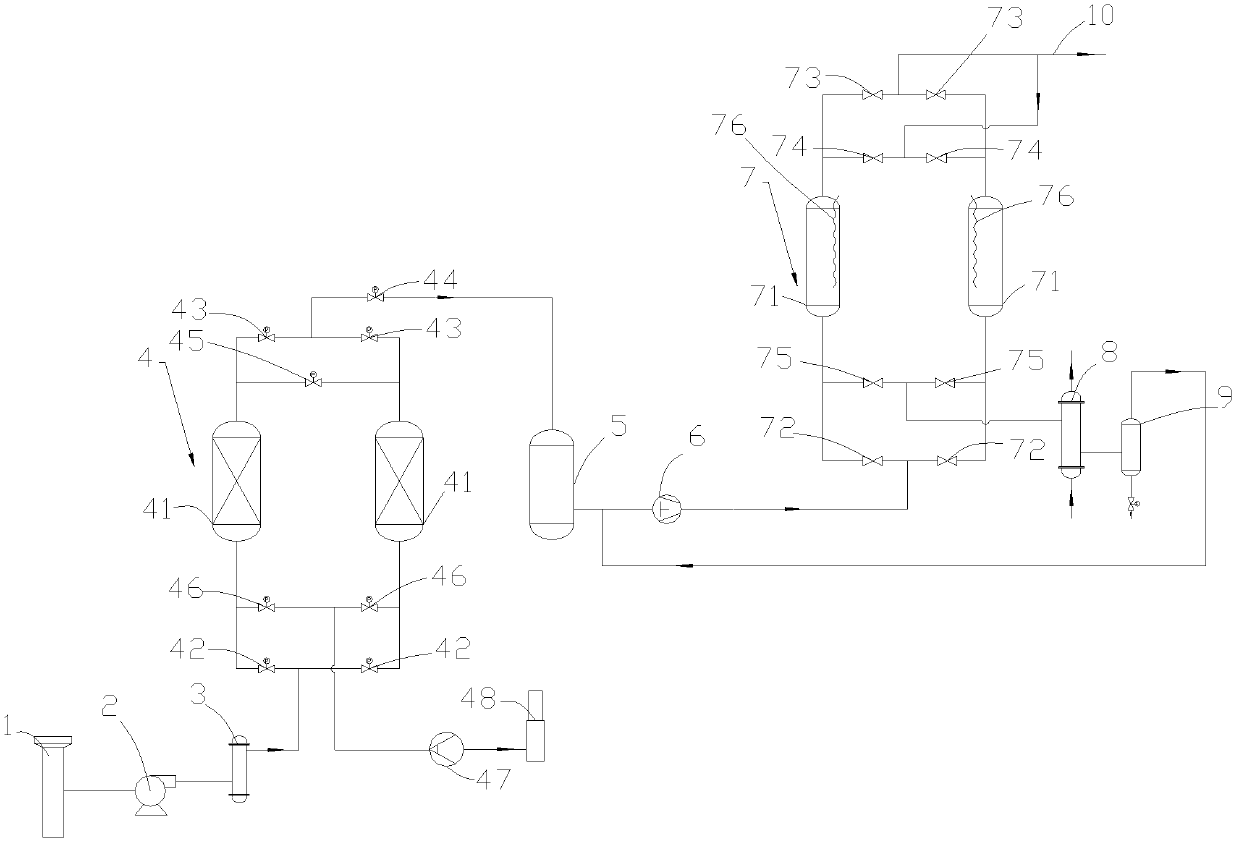

[0021] The structure of the present invention will be further described below in conjunction with the accompanying drawings.

[0022] The special oxygen generating device for ozone machine described in the present invention provides oxygen with a concentration of 90% to 95% for industrial ozone machines. The normal pressure dew point of oxygen reaches below -60°C required by the ozone machine, and the energy consumption per unit of oxygen is less than 0.4KW. h / m 3 ·O 2 .

[0023] exist figure 1 In the process, the air is filtered by the filter muffler 1, blown into the cooler 3 by the blower 2, and then enters the adsorption tower 41. The adsorption tower 41 is densely filled with activated alumina, 13X molecular sieve and adsorbent sequentially from the bottom to the top. After removing moisture, nitrogen, carbon dioxide and other impurity gases in the air, oxygen flows out from the top of the adsorption tower 41 . There are two adsorption towers 41 in the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com