Buoyancy tank and afloat buoyancy tank joining process

A technology of floating tanks and crafts, which is applied to floating buildings and other directions, can solve the problems of high requirements for operators and poor working environment, and achieve the effects of improving the working environment, reducing the difficulty of closing, and shortening the closing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described with reference to the accompanying drawings:

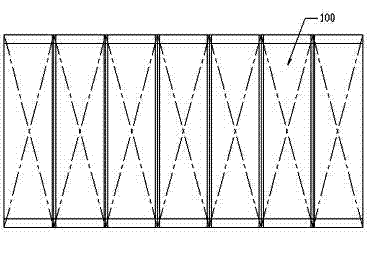

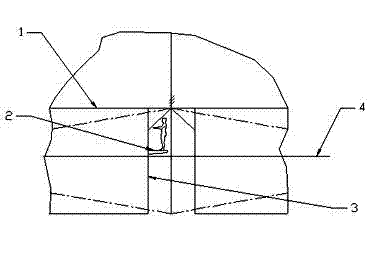

[0016] like Figure 1 to Figure 3 As shown, in the pontoon in this embodiment, the connection structure between the pontoons 100 is arranged on the outer side wall 3 of the pontoon below the deck 1 of the pontoon and above the water surface 4 . A grid channel 2 is also provided on the outer side wall 3 of the pontoon under the pontoon deck 1 and above the water surface 4; the distance between the bottom surface of the grid channel 2 and the pontoon deck 1 is greater than or equal to 1.8 meters, In order to facilitate the staff to stand in the grille channel 2 to carry out the closing construction operation.

[0017] like image 3 , 4 and Figure 5 As shown, the above-mentioned floating box water closing process of the floating box includes the following steps: (a) a connection structure between the floating boxes 100 is arranged on the outer side wall 3 of the floating box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com