Ladder stand as well as stay wire type steel tube tower

A technology of steel pipe tower and climbing ladder, applied in the direction of tower, ladder, building type, etc., can solve the problems of increasing the production cost of the iron tower, increasing the weight of the iron tower and material waste, and achieving the effect of improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

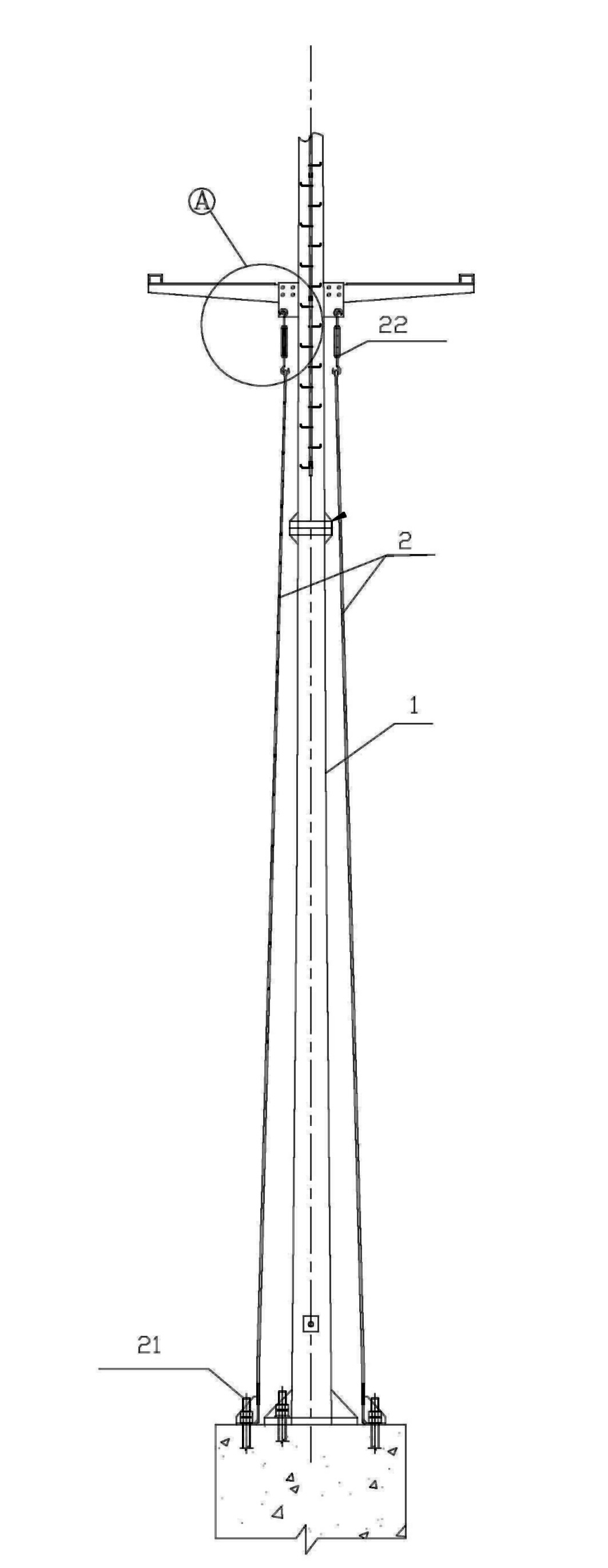

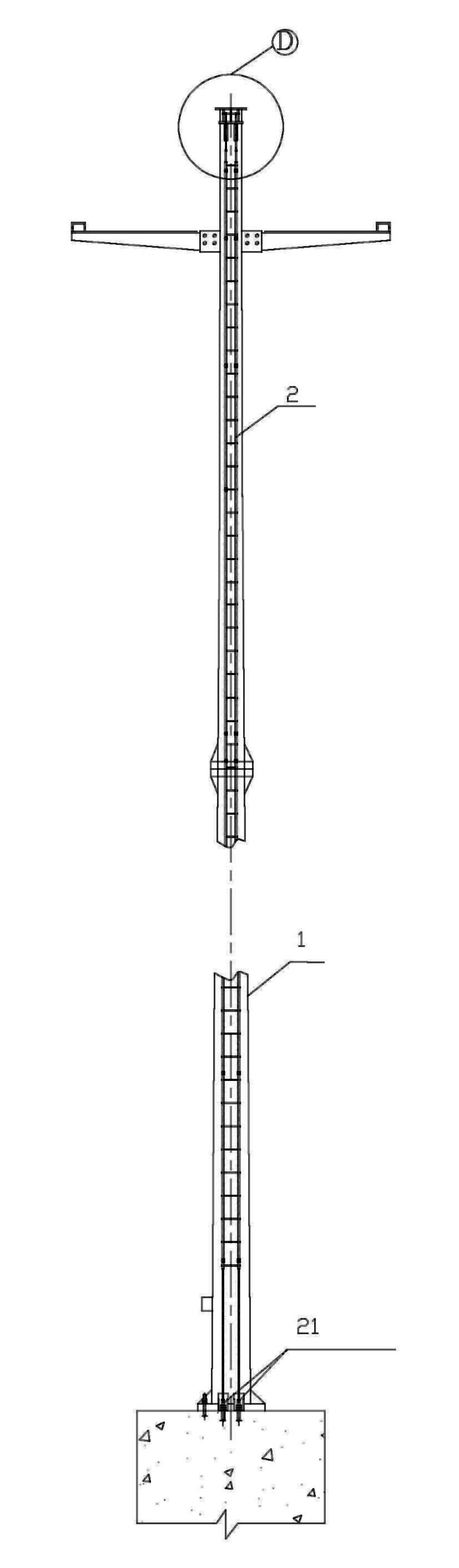

[0015] Such as figure 1 , figure 2 , image 3 As shown, the ladder and guy wire type steel pipe tower includes a steel tower body 1 and a ladder 2, the ladder 2 is installed obliquely, and its inclination angle is greater than the inclination angle of the inclined tower bar of the iron tower body, the lower end of the ladder 2 is fixed in the ground, and the upper end is fixed on the iron tower body.

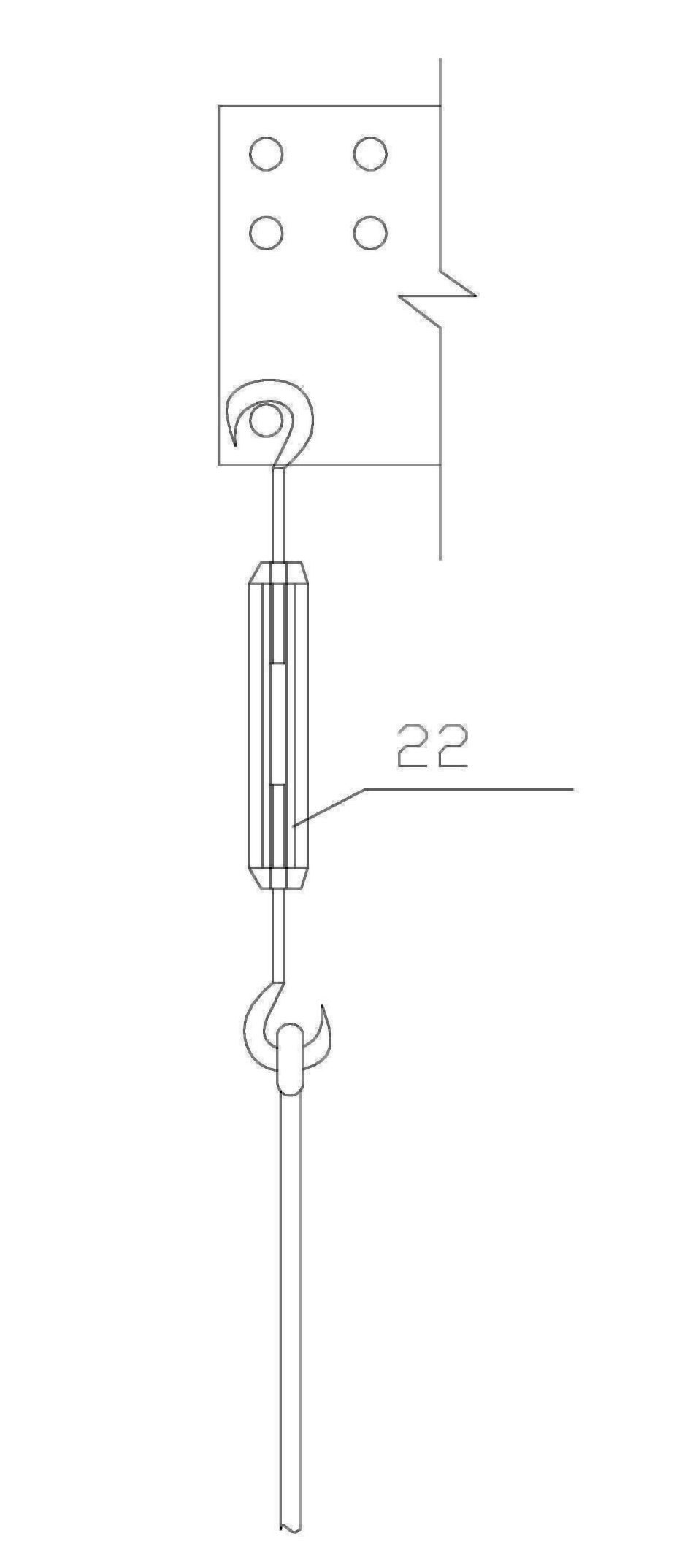

[0016] Such as figure 1 and Figure 1.1 As shown, the iron tower body 1 is a linear tower, and two ladders are installed symmetrically on both sides of the iron tower body 1; the ladder 2 is a single-pole ladder, and the lower end of the ladder 2 is fixed on the foundation with foot bolts 21, and the upper end is fixed with turnbuckle screws 22 hooks are hung on the upper cross arm of the iron tower body.

[0017] Such as figure 2 and Figure 2.1 As shown, the iron tower body 1 is a terminal tower, a climbing ladder 2, and the climbing ladder 2 is a double-pole ladder co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap