Method for testing annular orientation of pipe

A technology of orientation degree and pipe material, which is applied in the analysis of solid directions by using sound wave/ultrasonic wave/infrasonic wave, which can solve the problems such as the difficulty in characterizing the degree of orientation in the circumferential direction of biaxially oriented pipe materials, achieve scientific and accurate test results, high test costs, and solve test difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The test method for hoop orientation degree of pipe mainly includes the following implementation steps:

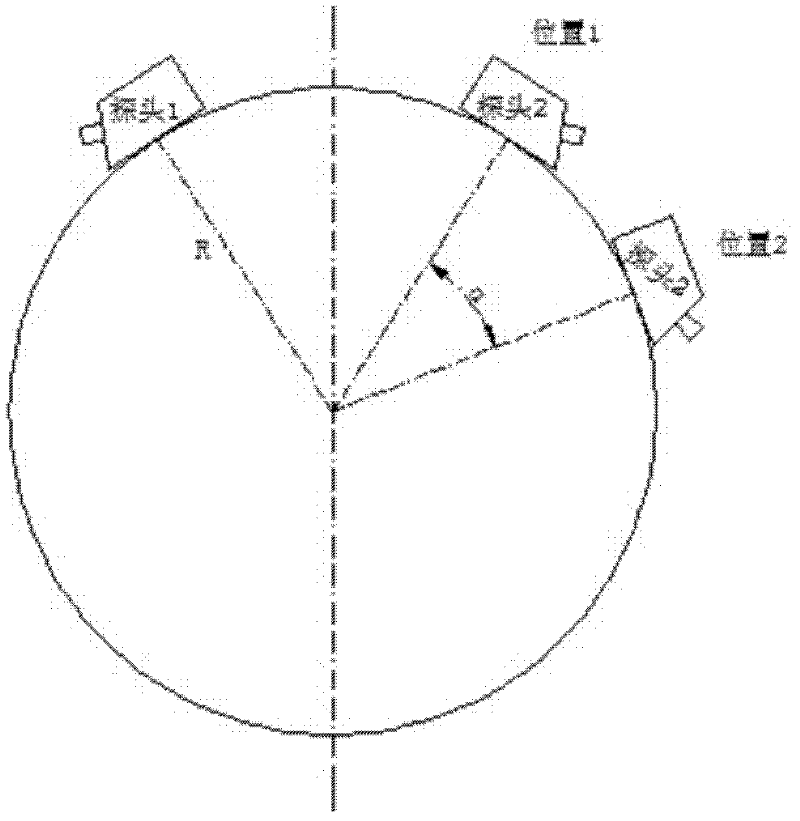

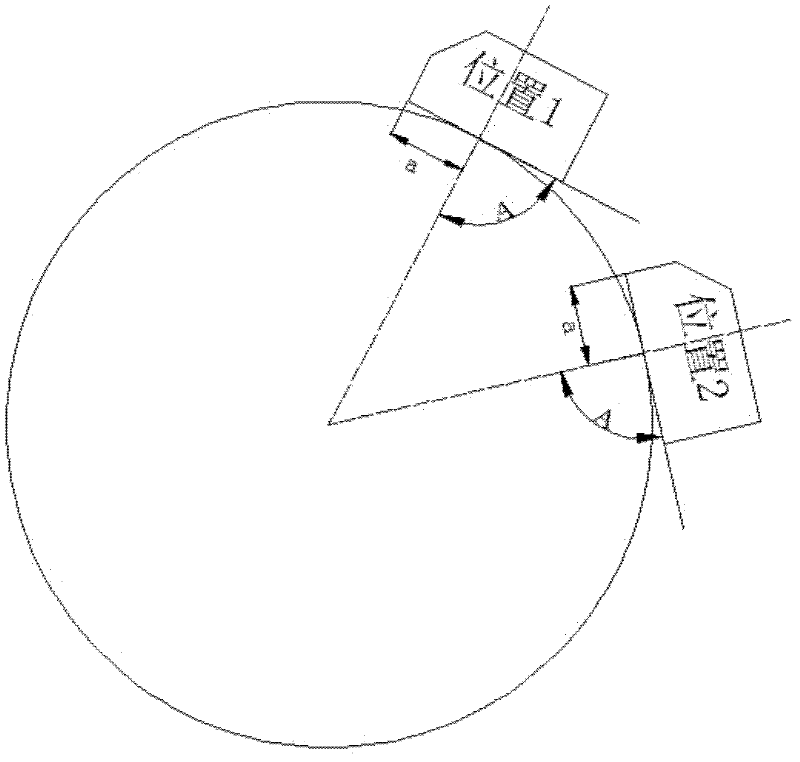

[0025] 1) The angle between the initial position of the probe should be moderate, about 10°, which will not affect the results. Set the rotation angle, measure the outer diameter and wall thickness of the pipe.

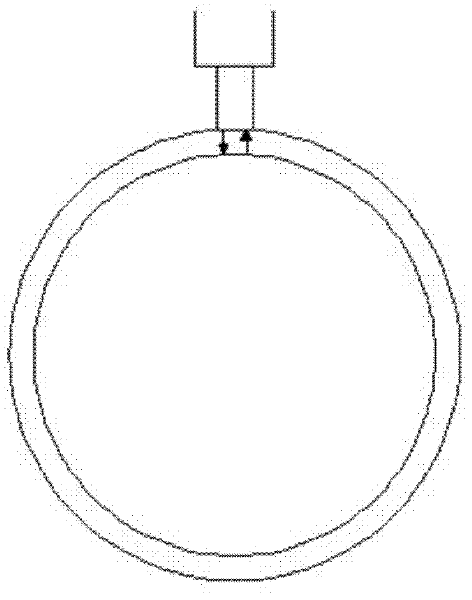

[0026] 2) Test the hoop ultrasonic velocity of the oriented pipe.

[0027] 3) Test the hoop ultrasonic velocity of a completely unoriented pipe material of the same material as the tested pipe material.

[0028] 4) Calculate the hoop orientation degree of the pipe according to the ultrasonic orientation degree formula (1).

[0029] The actual operation process and results are as follows:

[0030] 1. Select an oriented PVC pipe with an outer diameter of 90mm and a wall thickness of 4mm. The outer diameter of the PVC pipe before expansion is 50mm and the wall thickness is 8mm. The rotation angle of the probe is 5°.

[0031] 2. Test the ultrasonic velocity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com