Ball valve airtightness test method and test system

An air tightness test, ball valve technology, used in fluid tightness test, liquid/vacuum test for liquid tightness, machine/structural component testing, etc. It can solve problems such as high test costs and save testing. The effect of equipment cost, simple structure, low cost and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

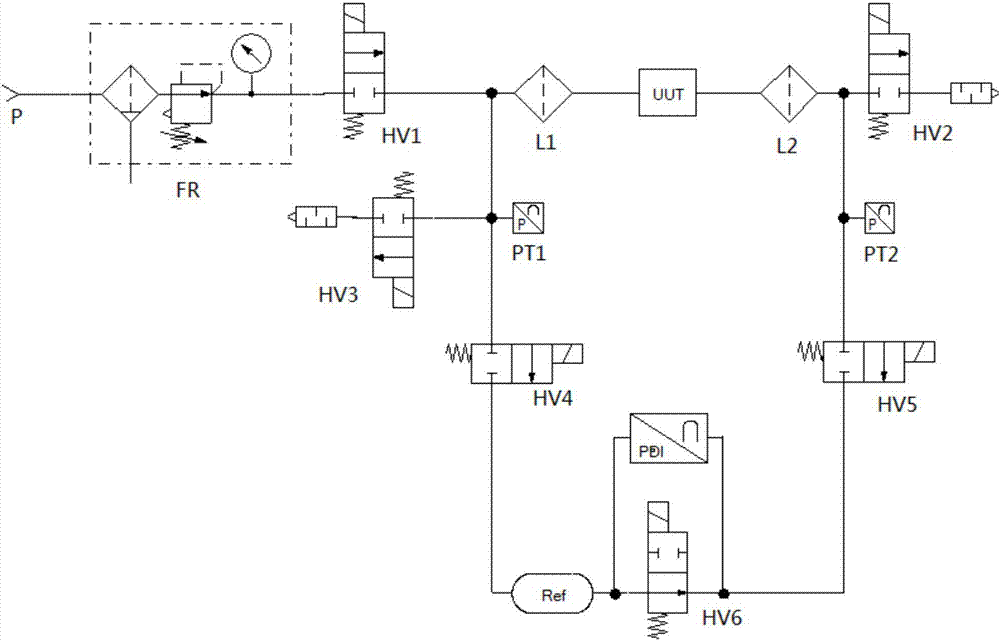

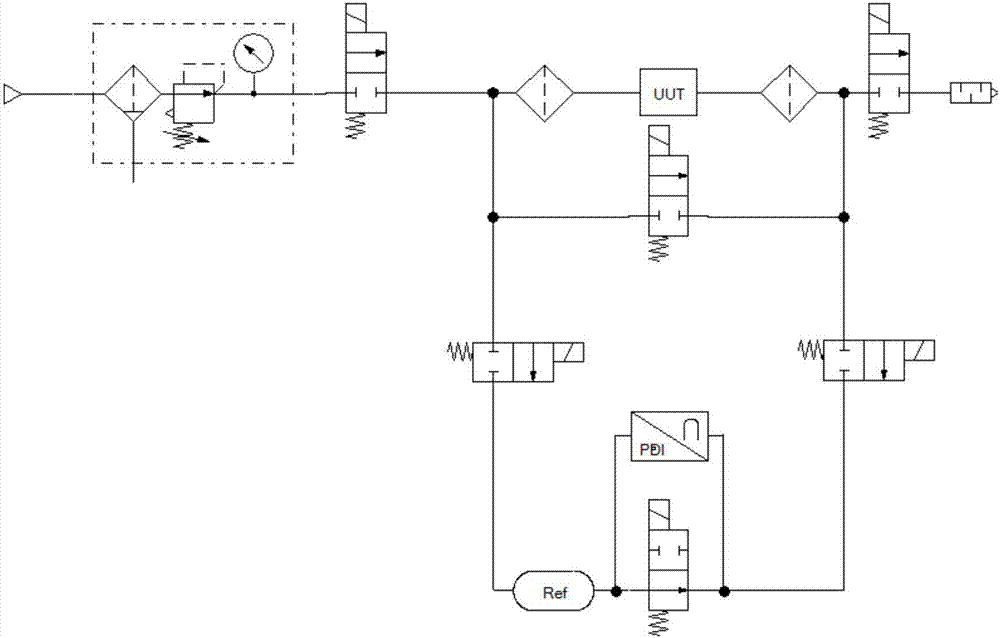

[0043] Such as figure 2 Shown: This embodiment is an automatic test system for external leakage and internal leakage testing of ball valves, including air source P, filter pressure regulating valve FR, inflation valve HV1, filter L, tested ball valve UUT, Filter L, exhaust valve HV2; when inflating, the air source P with a pressure of 0.1-1.2MPa passes through the filter pressure regulating valve FR, the inflation valve HV1, the ball valve UUT under test, the filter L, and is discharged from the exhaust valve HV2. Used here, the filter pressure regulating valve FR and the filter L filter the gas entering the test system to effectively protect the test system. On both sides of the tested ball valve UUT, there is a conduction valve HV3, and the outlet of the charging valve HV1 is connected with a standard chamber Ref. The other outlet is connected to the high pressure end of the differential pressure sensor PDI, and the low pressure end of the differential pressure sensor PDI ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com