Heat exchanger

A technology of heat exchanger and heat dissipation module, which is applied in the cooling of instruments, components of instruments, instruments, etc. It can solve the problems of blocking the opening of the flow channel, unable to provide air volume, and increasing the height of the box.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

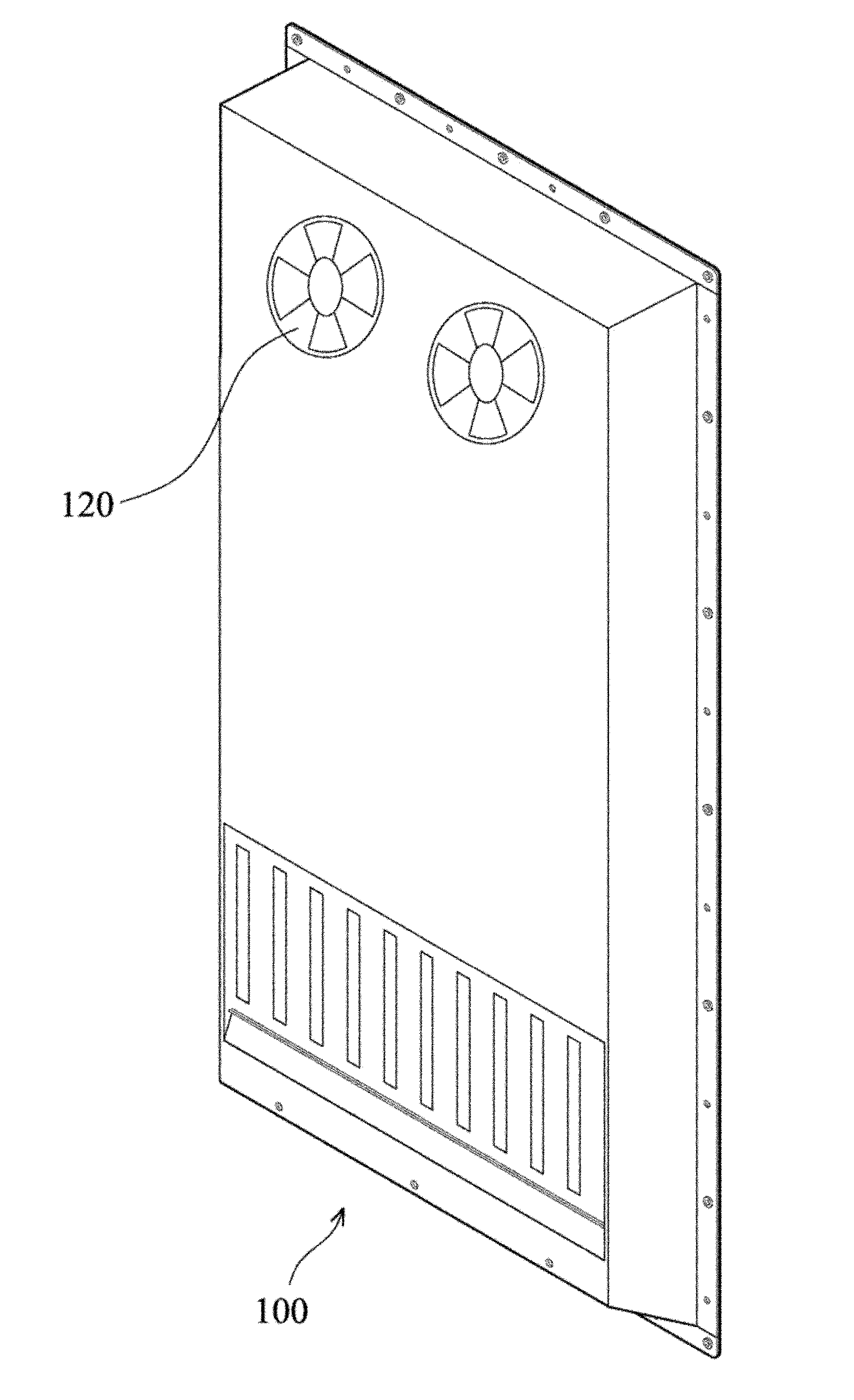

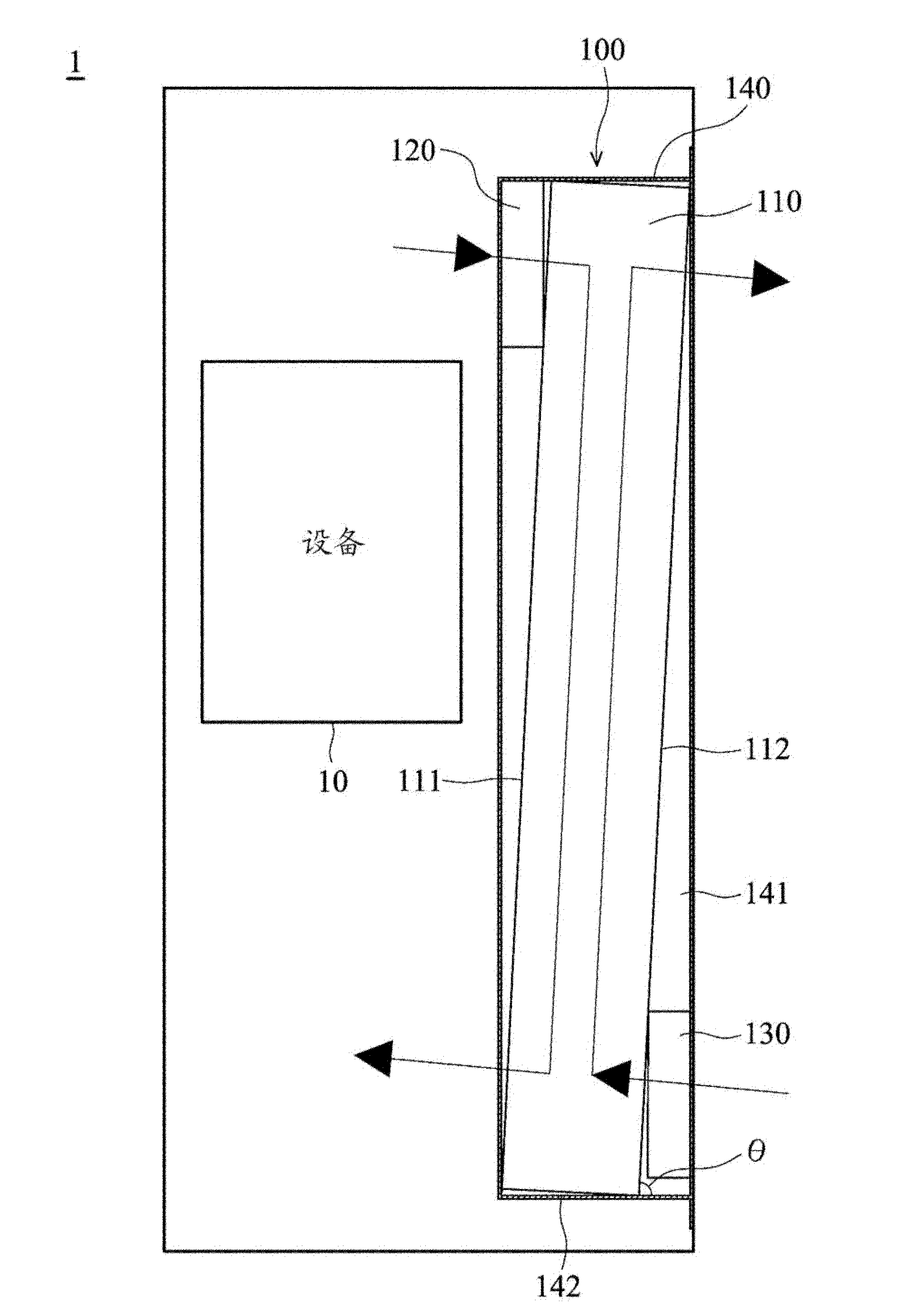

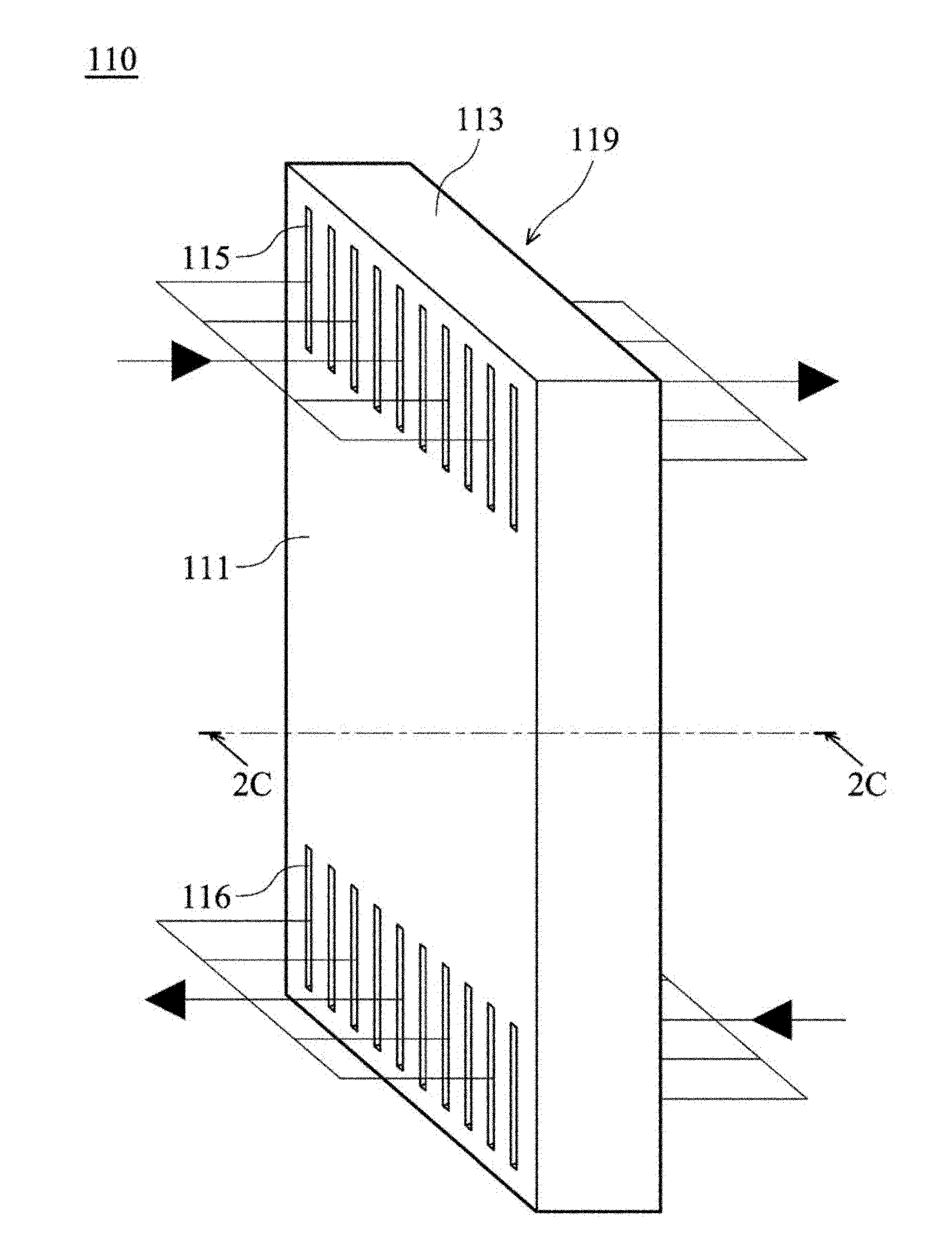

[0034] Figure 1A is a perspective view showing a heat exchanger 100 according to an embodiment of the present invention. Figure 1B It shows the situation where the heat exchanger 100 according to the embodiment of the present invention is installed in a target system 1 . refer to Figure 1A , Figure 1B , the heat exchanger 100 of the embodiment of the present invention includes a heat dissipation module 110 , an inner circulation fan 120 , an outer circulation fan 130 and a box 140 . refer to Figure 2A , Figure 2B The cooling module 110 includes a module body 119, a plurality of first air inlets 115, a plurality of first air outlets 116, a plurality of second air inlets 117, a plurality of second air outlets 118, a plurality of first flow channels 1101 and a plurality of a second flow channel 1102. collocation reference Figure 2C , which is displayed Figure 2A 2C-2C in the sectional view, the plurality of first flow channels 1101 and the plurality of second flow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com