Gear cleaning device for gear roller of titanium sponge single roller crusher

A titanium sponge single roller and crusher technology, which is applied in grain processing and other directions, can solve problems such as sponge titanium accumulation, sponge body damage, and hindrance to automatic production of sponge titanium, so as to reduce friction, reduce tooth picking force, and improve tooth picking effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

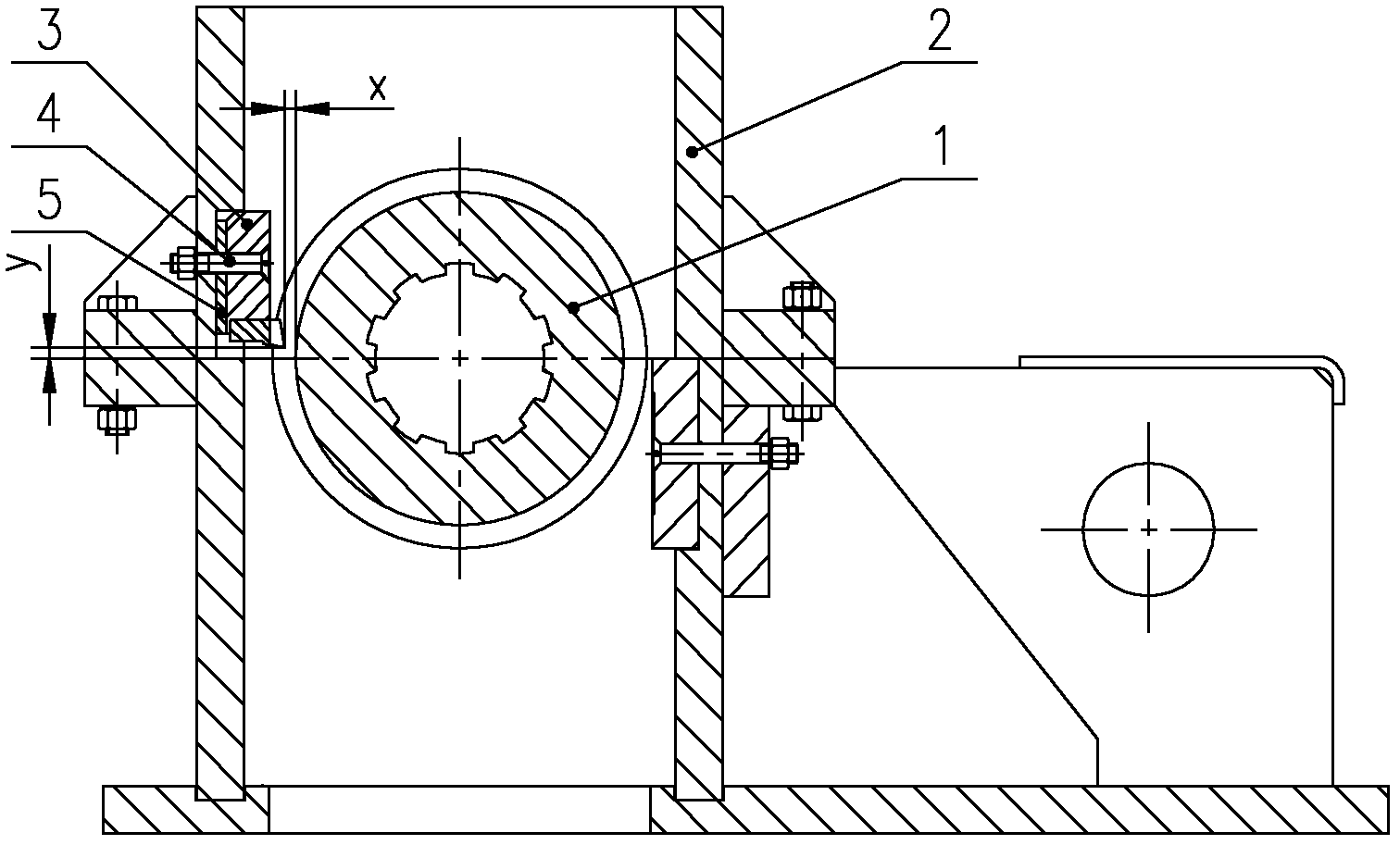

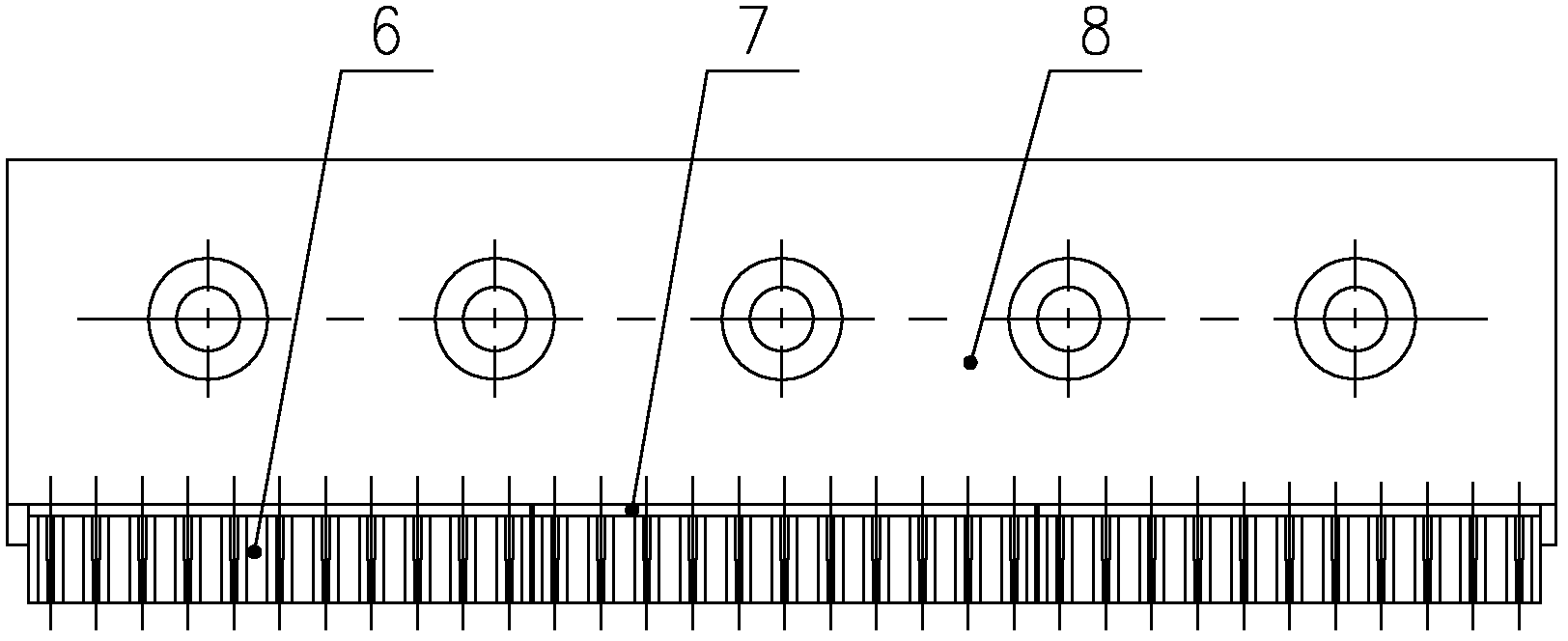

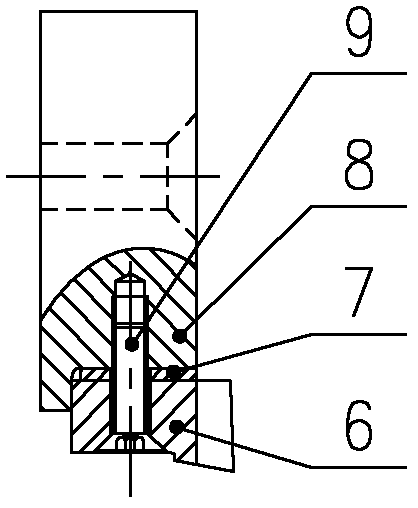

[0018] Such as figure 1 The tooth-picking device of the toothed roller of the sponge titanium single-roller crusher shown mainly consists of a toothed roller (1), a casing (2) and a tooth-picking knife (3). There is a square slot on the inner side of the casing (2), the length and width of which are larger than that of the tooth picking knife (3), and the tooth picking knife (3) is installed in the square slot of the casing (2) of the crusher through the bolt (4). One side of the toothed roller (1) is opposite to the jaw plate of the crusher; the tooth top of the toothed knife (3) is inserted into the tooth groove of the toothed roller (1), and a certain gap is left; the adjusting pad (5) is installed in the casing ( 2) and the gear picking knife (3), used to adjust the radial distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com