A method for processing the lock opening of the last rotor blade with threads

A processing method and rotor technology, applied in the field of steam turbines, can solve problems such as long processing time, difficult processing, and complex structure, and achieve the effects of simple operation, reduced processing cost, and improved processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

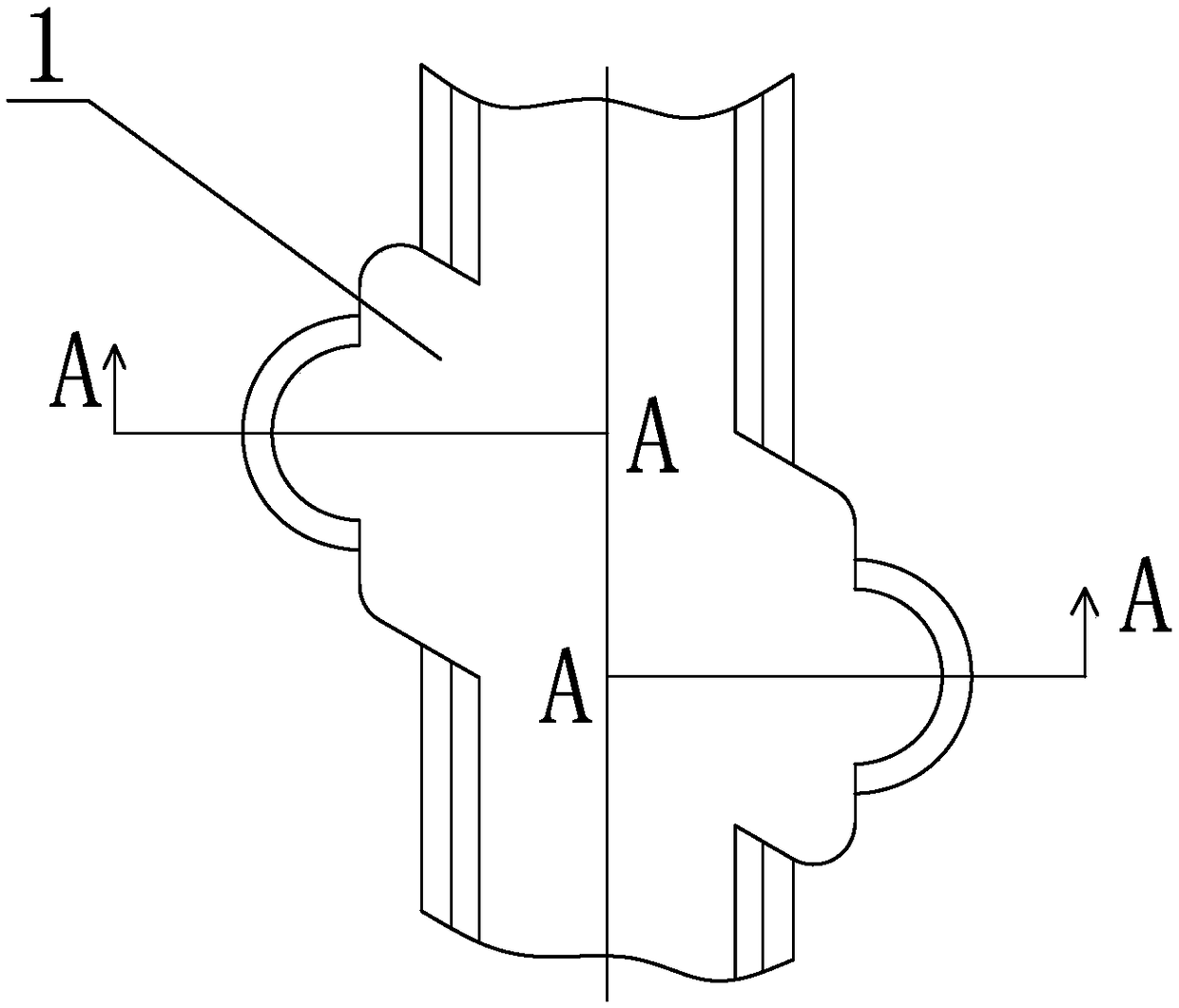

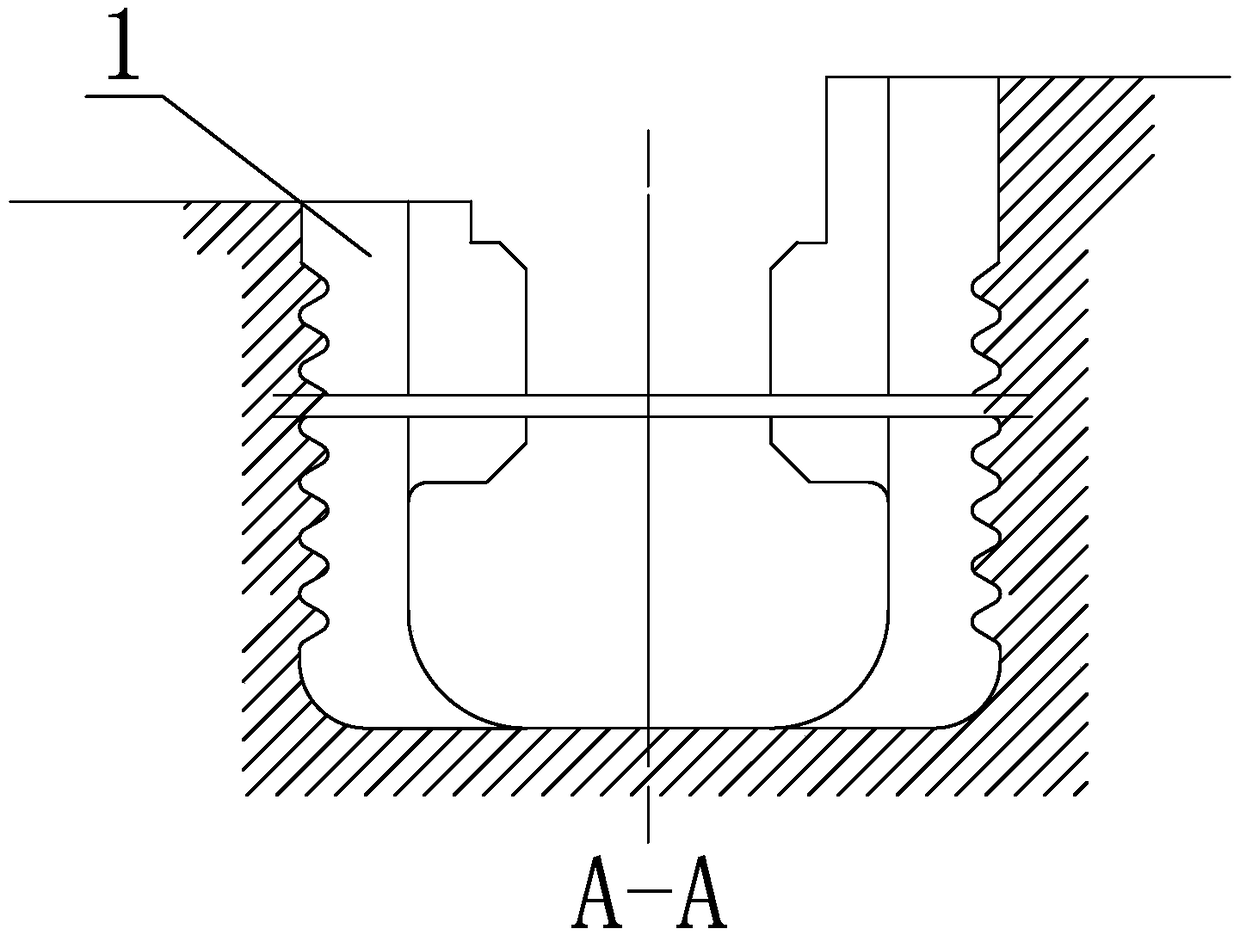

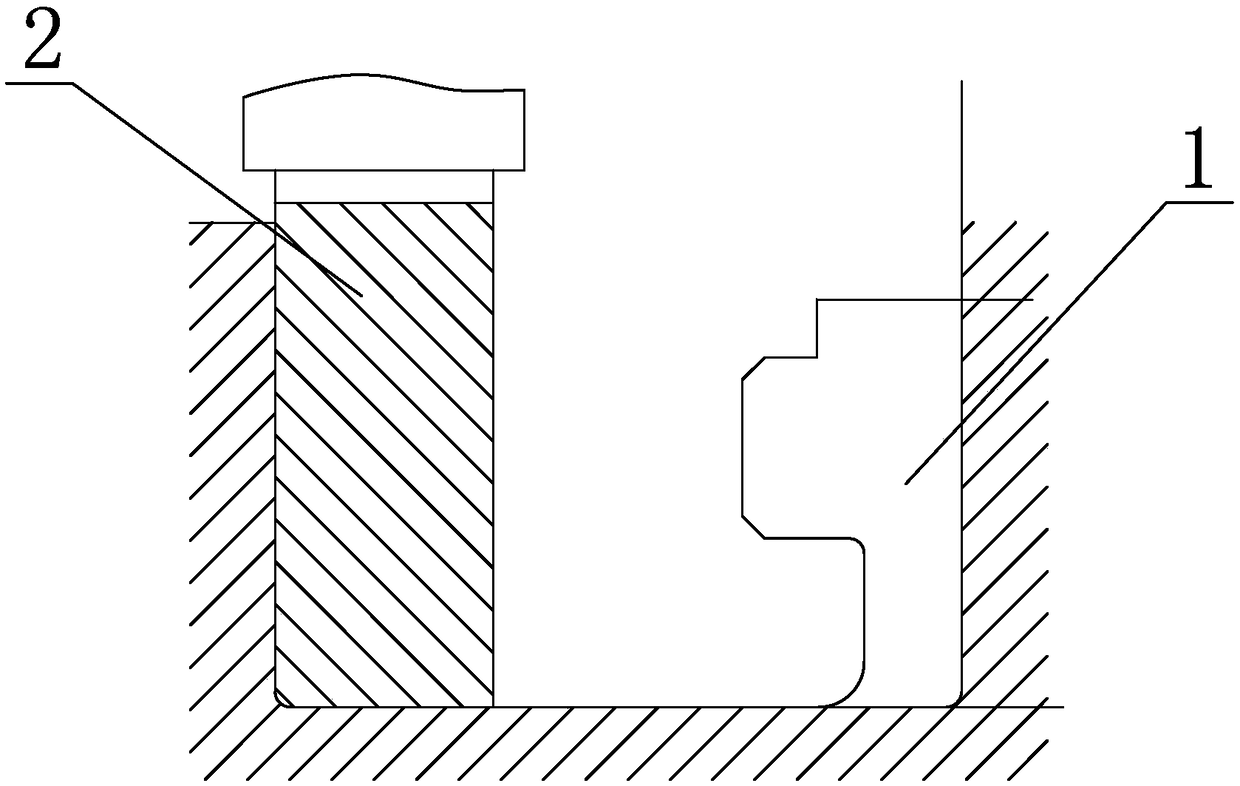

[0035] Specific implementation mode one: combine Figure 1 to Figure 6 Describe this embodiment, a method for processing a threaded rotor end blade lock in this embodiment, the processing method includes the following steps,

[0036] Step 1. Install and align the rotor:

[0037] Install the rotor on the boring machine through the bracket, align the position of the rotor T-shaped blade root and blade 1 lock with the main shaft of the boring machine, and align the rotor at the same time;

[0038] Step 2. Use the first end mill 2 to roughly machine the lock mouth profile of the rotor T-shaped blade root and blade 1:

[0039] Install the first end mill 2 on the boring machine, perform tool setting on the first end mill 2 according to the lock shape of the rotor T-shaped blade root and end blade 1, use the program according to the zero point of the tool that has been aligned, and pass the first vertical The milling cutter 2 rough-machines the lock mouth profile of the rotor T-sha...

specific Embodiment approach 2

[0048] Specific implementation mode two: combination image 3 and Figure 4To describe this embodiment, the rotational speed of the first end mill 2 in step 2 of this embodiment is 300 r / min; the cutting amount is 0.08 mm / r. With this arrangement, the first end mill 2 is used to roughly machine the profile of the rotor T-shaped blade root and terminal blade 1 lock, which ensures the machining accuracy of the rotor T-shaped blade root and terminal blade 1 lock profile, shortens the processing time, and effectively improves the The machining efficiency of the final blade lock. Other compositions and connections are the same as in the first embodiment.

specific Embodiment approach 3

[0049] Specific implementation mode three: combination Figure 4 The present embodiment will be described. In step 3 of the present embodiment, the rotational speed of the second end mill is 310 r / min, and the cutting amount is 0.09 mm / r. With this setting, the second end mill is used to finish machining the rotor T-shaped blade root and final blade 1 lock, which ensures the machining accuracy of the rotor T-shaped blade root and final blade 1 lock, shortens the processing time, and effectively improves the lock of the final blade. Mouth processing efficiency. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com