Processing method for internal sphere of split bearing seat

A technology of splitting bearings and processing methods, which is applied to spherical grinders, metal processing equipment, manufacturing tools, etc., and can solve the problems of increasing production costs and high prices of domestic iron and steel enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

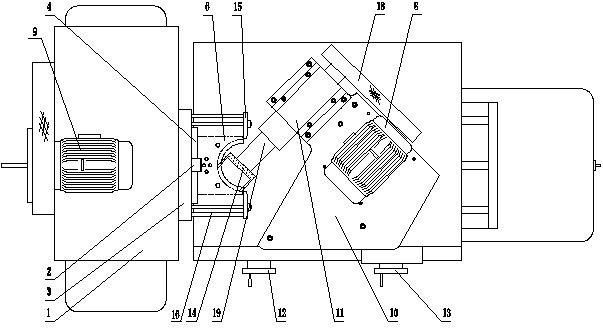

[0035] see figure 1 , a processing method for splitting the inner spherical surface of a bearing seat, comprising the following steps:

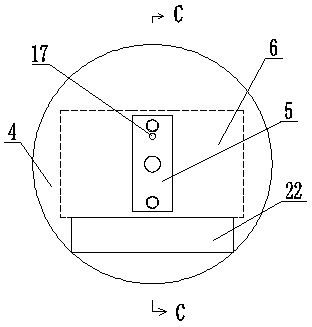

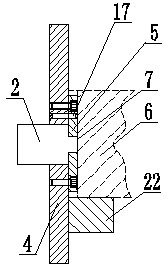

[0036] Step 1, install the positioning mechanism in the spherical surface processing device of the split bearing seat on the workpiece shaft 2 connected to the machine tool motor 9, that is, the positioning plate 3, the transition plate 4 and the positioning key 5 in the positioning mechanism are sequentially set on the workpiece shaft 2, and a pressing rod 16 is symmetrically fixed on the positioning plate 3. see figure 2 and image 3 , the positioning plate 3, the transition plate 4 and the positioning key 5 are affixed to the workpiece shaft 2, and the positioning plate 3 and the transition plate 4 are fixed, and the transition plate 4 and the positioning key 5 are fixed after being positioned by the posi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap