Threaded core pulling device with automatically reset thread starting point

A technology of automatic reset and core-pulling device, applied in the field of thread core-pulling device, can solve the problems of easy to produce waste, low production efficiency, not suitable for large-scale production requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

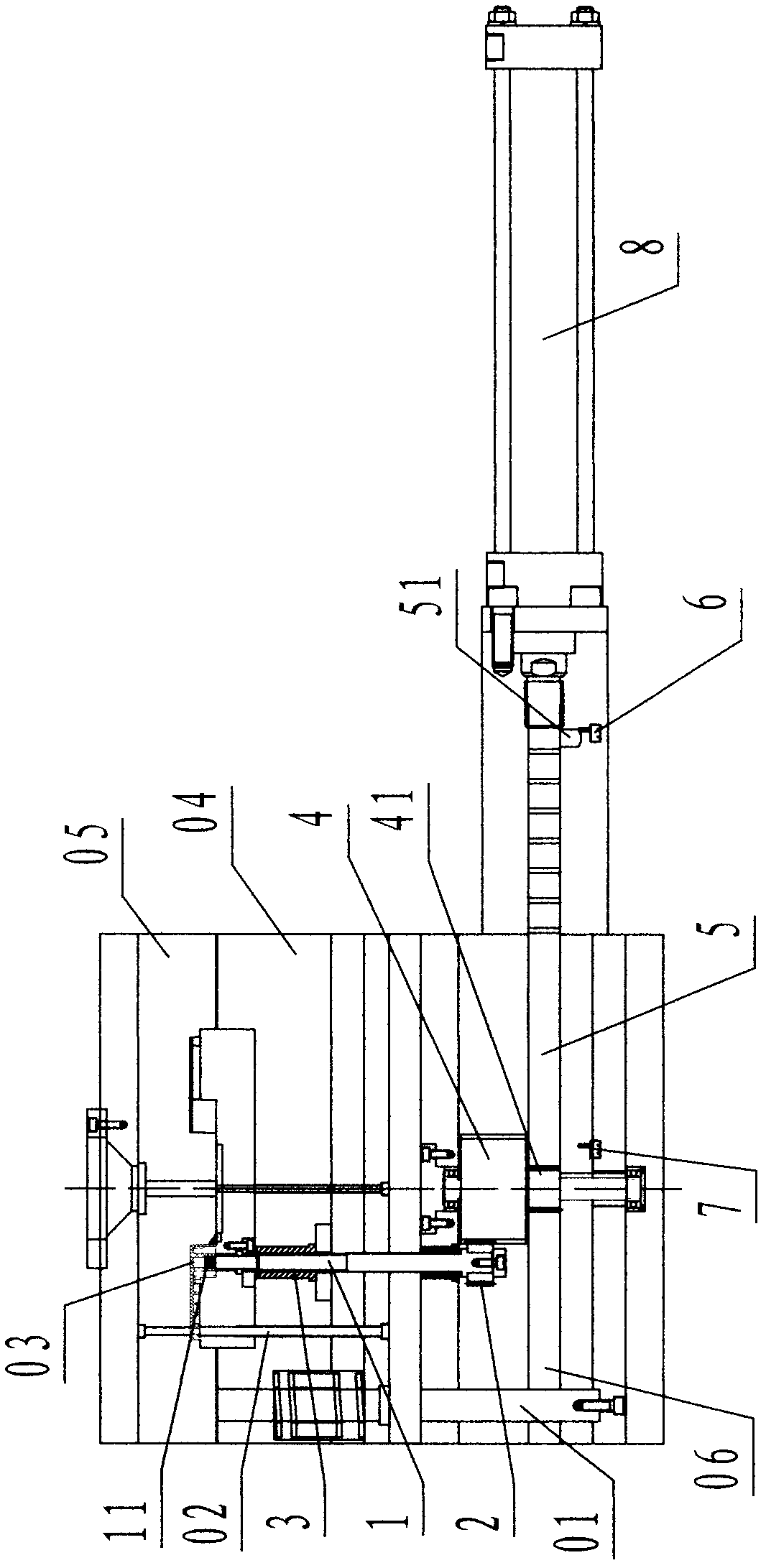

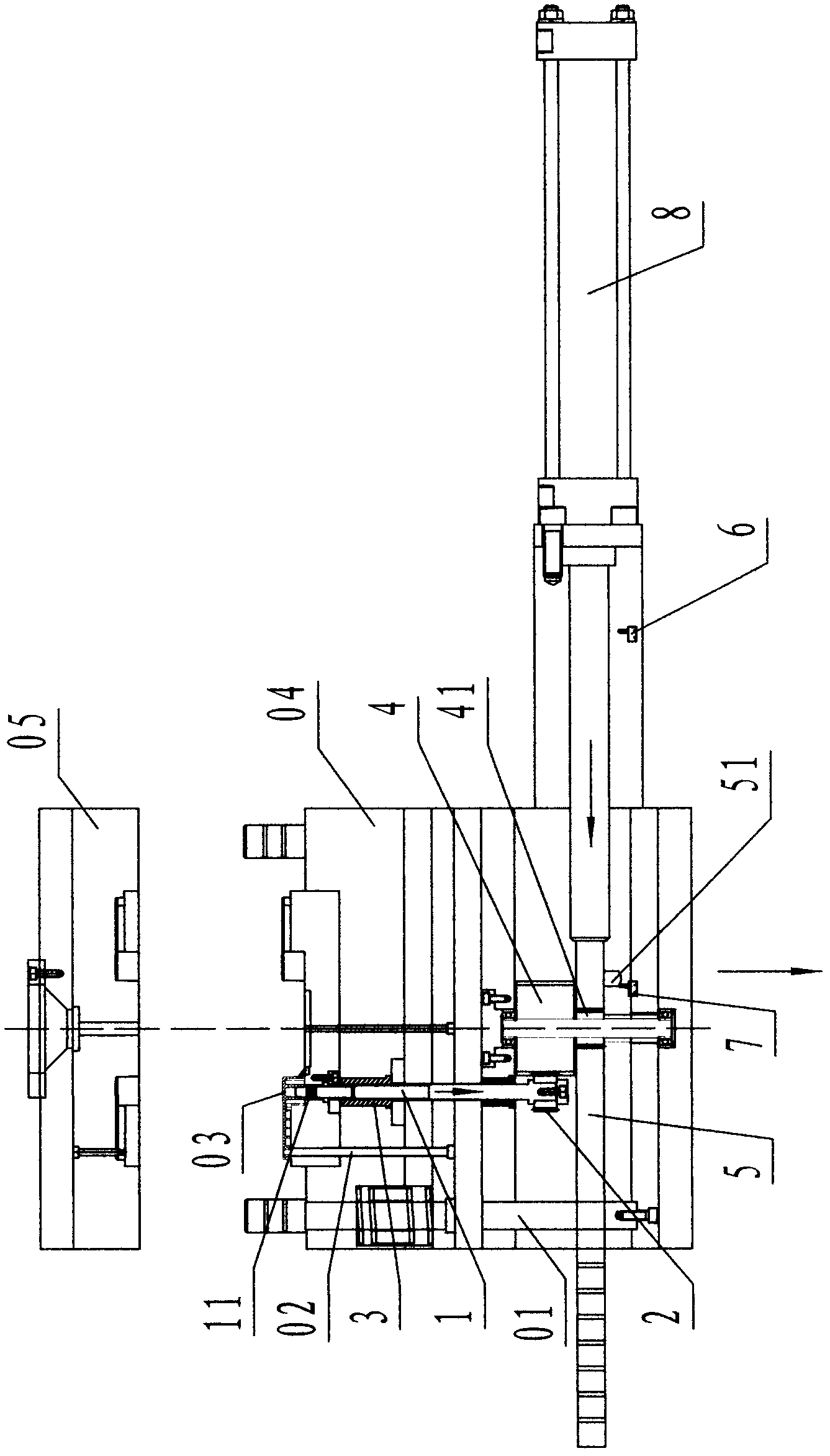

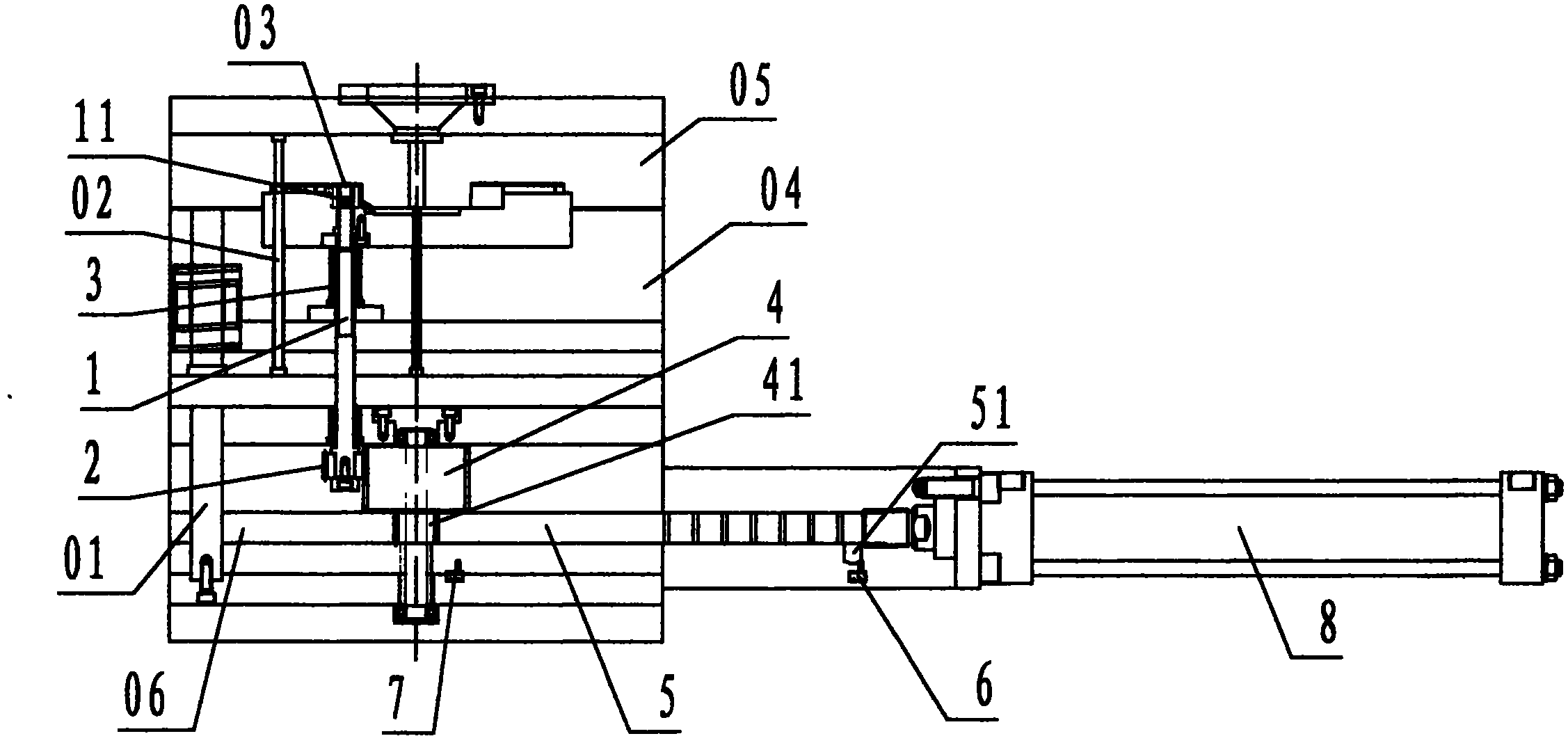

[0021] refer to figure 1 , a thread core-pulling device of the present invention that automatically resets the thread starting point, including a screw 1, a thread core 11, a B gear 2, a nut sleeve 3, a transmission gear 4, an A gear 41, a rack 5, and a limit block 51 , reset travel switch 6, escape travel switch 7, oil cylinder 8, wherein: described screw rod 1 is the steel component of cylindrical rod shape, and cylindrical surface is provided with external thread; Cylindrical screw-shaped thread core 11; the pitch of the external thread of the screw rod 1 is equal to the pitch of the thread core 11; the bottom end of the screw rod 1 is fixedly connected with the B gear 2 of the steel spur gear;

[0022] The nut sleeve 3 is a cylindrical step-shaped bronze nut with an internal thread in the central inner hole, and the internal thread of the nut sleeve 3 is slidingly matched with the external thread of the screw rod 1;

[0023] The transmission gear 4 and the A gear 41 are s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com