Method for engraving gravure roller

A technology of gravure plate rolls and plate rolls, which is applied in the engraving field of gravure plate rolls to achieve the effects of improved resolution, high ink content, and high definition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

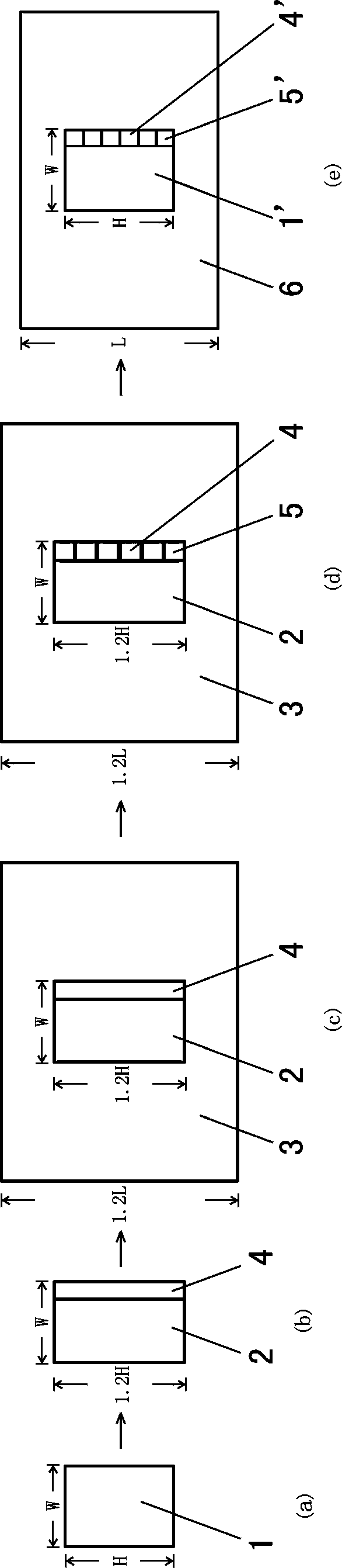

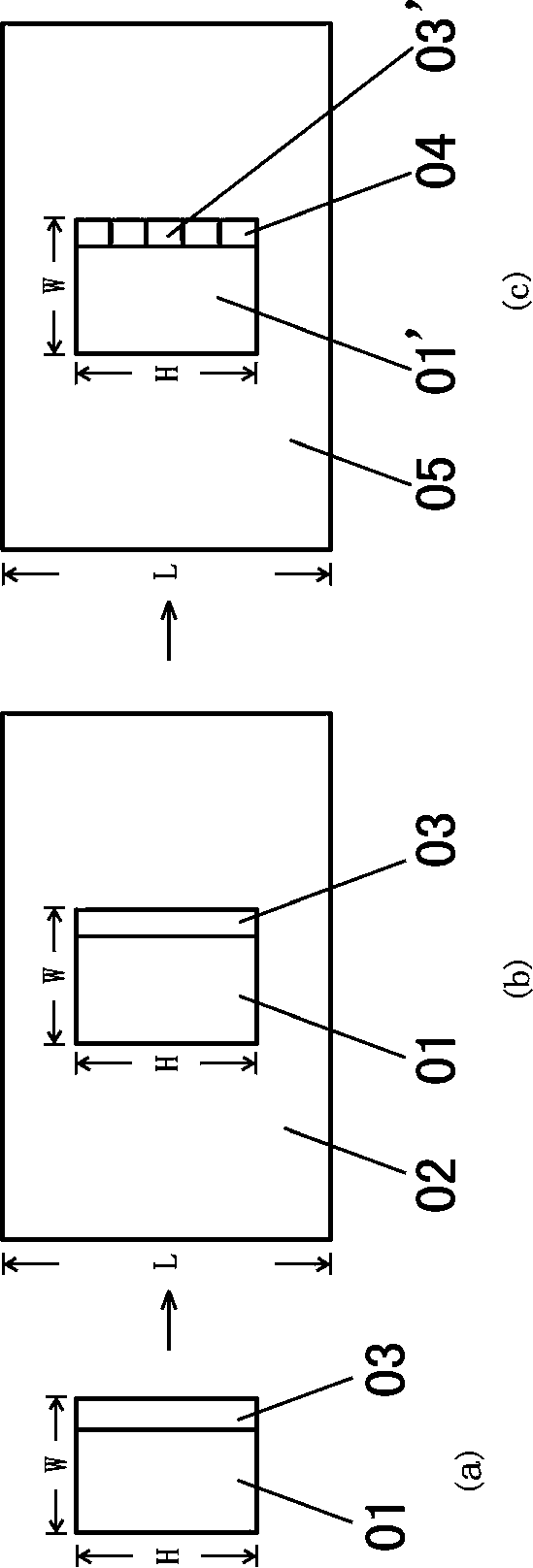

[0025] Combine below figure 1 The engraving method of the gravure roll of the present invention is described in detail.

[0026] In the present embodiment, the engraving method of gravure plate roll comprises the following steps:

[0027] (1) Process the design pattern (such as cutting) according to the requirements of the plate-making power of attorney, so that the design pattern 1 is consistent with the size of the target pattern;

[0028] The above design pattern 1 is designed according to the target pattern to be printed, and the design pattern 1 adopts a tiff image with a resolution of not less than 600dpi;

[0029] The size of the processed design pattern 1 is the size required on the plate-making power of attorney; the pattern size includes the width and height of the pattern, where the width of the pattern is the size of the pattern in the axial direction of the plate roller body, and the height of the pattern is the size of the pattern on the plate. Dimensions in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com