Device and method for applying an adhesive friction increasing material on an upper surface batch of a stack layer

A technology of static friction and surface parts, which is applied in the field of a device on at least one surface part, can solve problems such as pollution, and achieve the effects of avoiding pollution, benefiting economy, and reducing material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

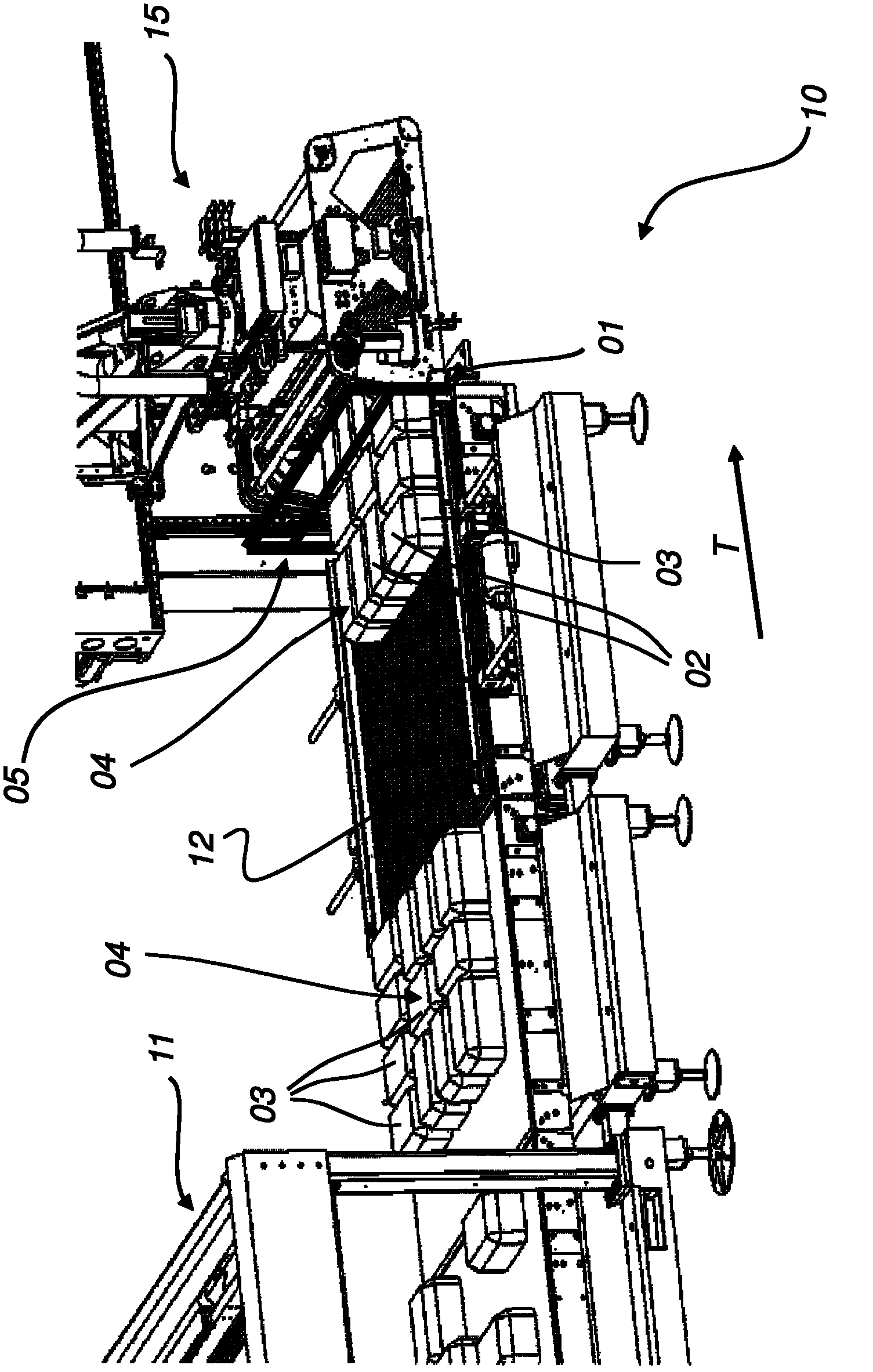

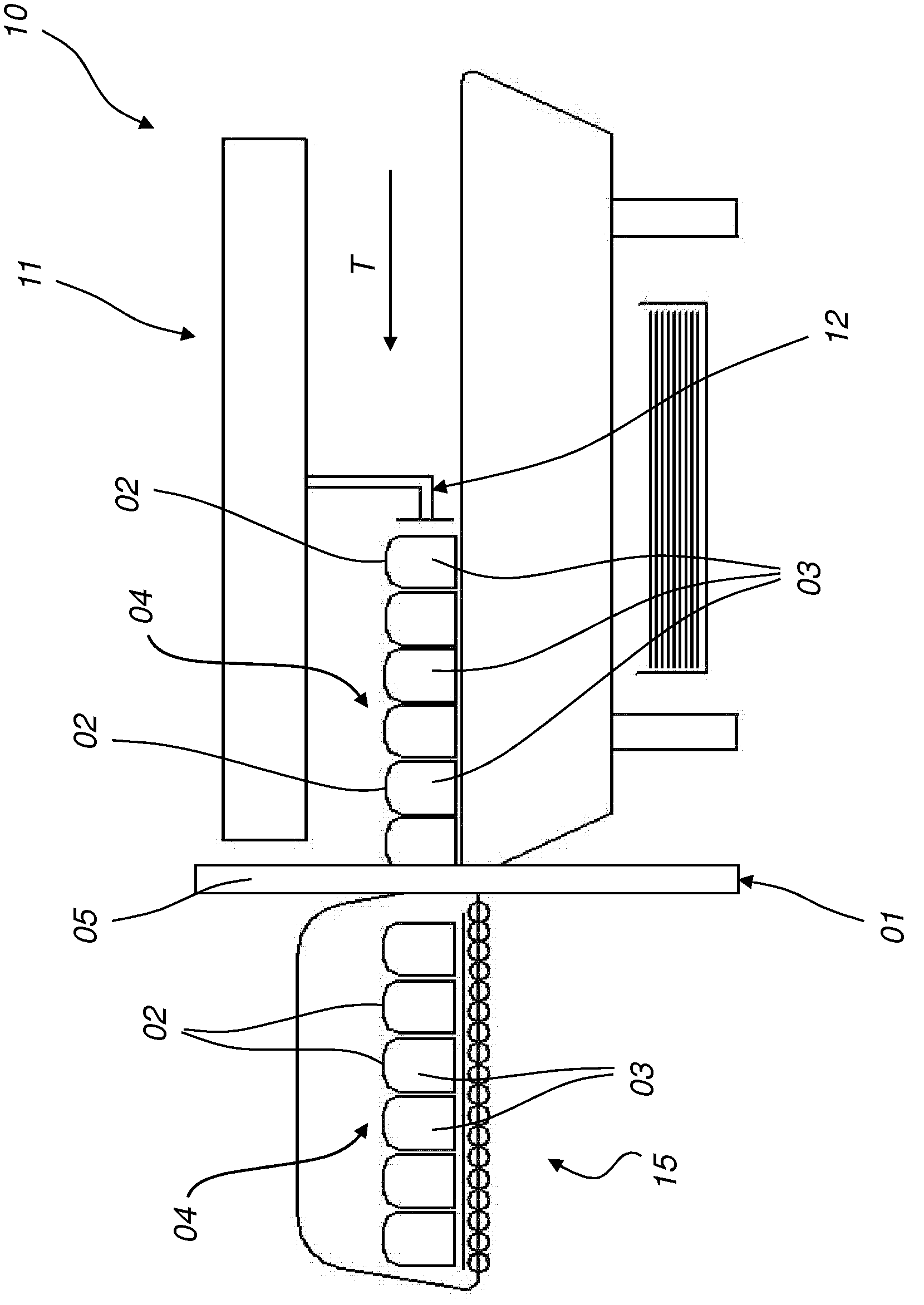

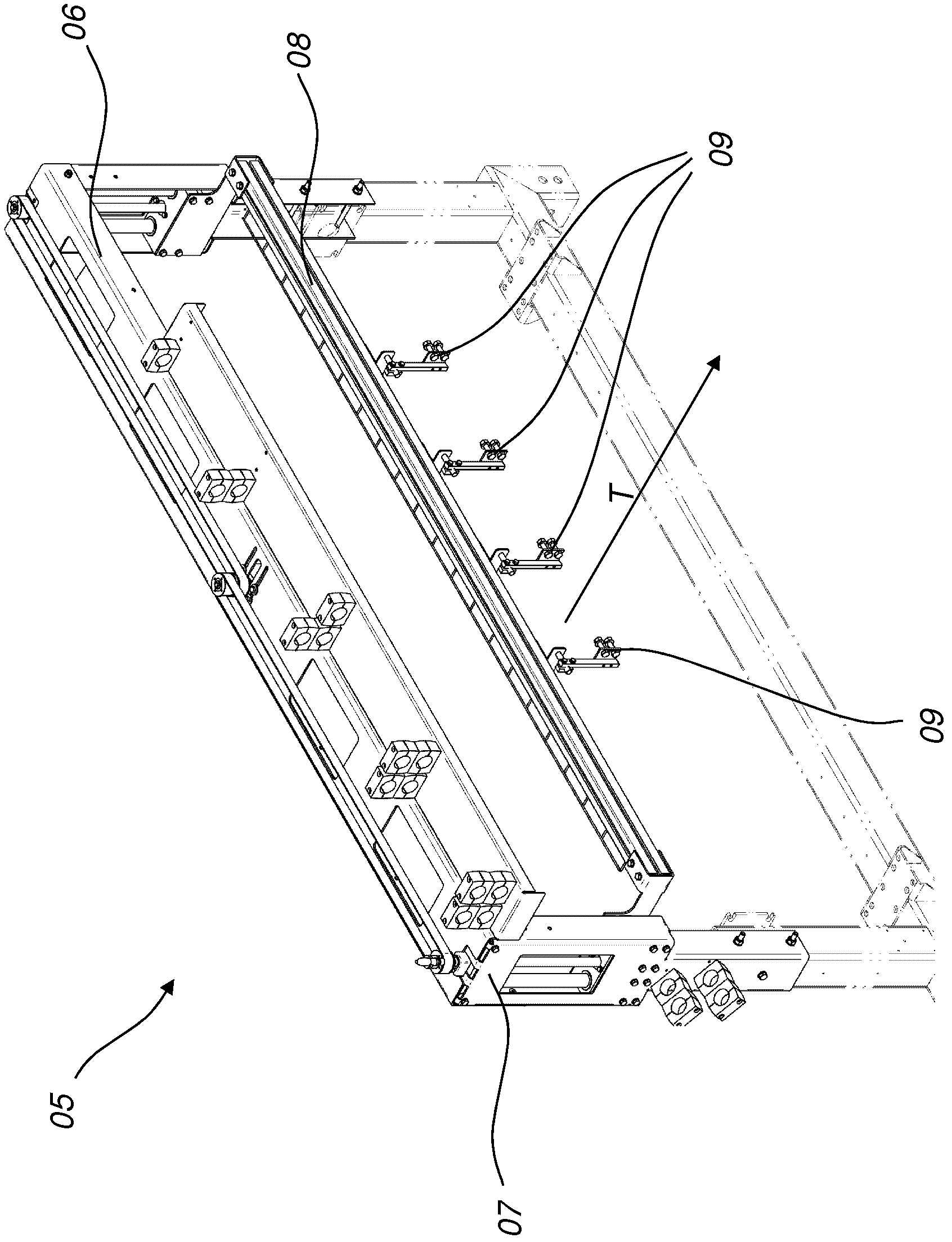

[0053] exist Figure 1 to Figure 3Device 01 shown in full or in part for applying at least one static friction-increasing medium to at least one surface portion 02 of at least one stacking unit 03 of at least one stacking layer 04 to be stacked into a stack , mainly comprising a nozzle system 05 provided for applying a static friction-increasing medium.

[0054] The nozzle system 05 is preferably arranged or arranged downstream of the workstation 11 for grouping a plurality of stacking units 03 into a stacking layer 04 , and here particularly preferably also for the The stack layer 04 is placed before the appliance 15 on the stack at the storage place. A correspondingly configured device 01 for applying at least one static friction-increasing medium to at least one surface portion 02 of at least one stack unit 03 of at least one stack layer 04 to be stacked into a stack thus comprises A nozzle system 05 for applying a static friction-increasing medium to the surface portion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com